The roof frame of the house is one of the key elements of the building. And if the frame is erected taking into account all the rules and compliance with the norms of the building, then it is highly likely that this building will serve its masters with faith and truth for more than a dozen years.

The device truss system.

The construction of the foundation and the construction of the walls of the house is coming to the finish line, and the beginning builders have a question: how to build a roof for the house? In fact, the choice of roofing and waterproofing material is large enough, and you can always buy it according to your financial possibilities. But the roof of the house require special attention. To begin, you will need to decide what kind of roof you see and choose its type: single, gable, hipped or sloping.

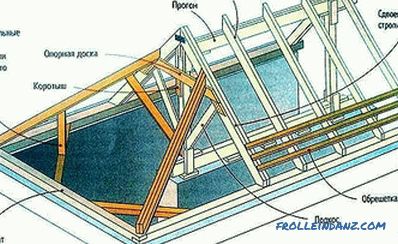

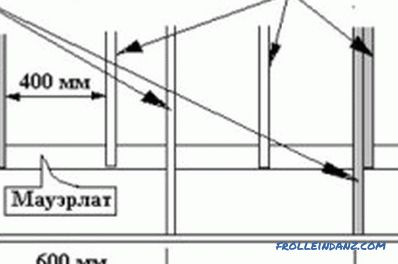

Scheme of assembling the roof of a frame house.

There are many advantages in making a roof frame with your own hands. First, you will have a great opportunity to save on payments for hired craftsmen. And secondly, you yourself will control the entire construction process and in the future will be able to prevent possible repairs.

Once you have decided on the type of roof, you can safely proceed to its construction. As an example, the process of erecting a gable roof frame is given, since it is this type that is the most common among the majority of buildings of private houses.

Choose a truss system

As you know, absolutely any truss system is a combination of two truss beams at the top of the structure. In the lower part of the design, the rafters are fixed due to the presence of the lower tie, and it can serve as an additional support that fixes the integrity of the structure.

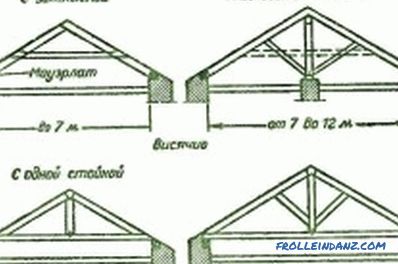

Scheme of types of roof systems.

There are two main types of truss systems: inclined and hanging. It is an inclined roof system used in the construction of private housing. The choice of truss system is usually due to some design features of the building itself. For example, if the distance between the two main bearing walls of the house is not less than 6 meters, you can safely equip the hanging truss system. Then the main carrier mass will take over the walls of the house. If the width between the walls is more than 6 meters, then the probability of subsequent sagging of the rafters is great. In this case, you need to take care of installing additional support.

Choosing a material for a solid frame

Before you make the roof frame, you will need to decide on the choice of material.

Design of the truss frame of the roof.

Wood is used as a material for the rafters, namely, edged board and timber. It is best to give preference to coniferous trees, since this material is composed of resin, which acts as a kind of natural antiseptic that prevents rot. The size of the edged board must comply with the following parameters 50x150 mm, and timber - 150x150 mm.

Also remember that the rafter system is not only the rafters themselves, but the racks and the purlins for them. These also include the attic floor, the batten and the counter lattice. If you plan to use the attic as a warehouse and do not plan to make additional living space out of it, then 50x150 mm boards will fit the attic floor. And if you have always dreamed of an attic, then you should get a timber of 150x150 mm.

For the contra-lattice and the batten, a 40x40 mm timber will fit, which is quite enough to support the weight of any roof. The main requirement for such a material is its sufficient frankness, because if the timber has deviations, the crate of the frame will be uneven and the weight of the roof will be unevenly distributed.

Required inventory

In addition, you will need the following materials and tools:

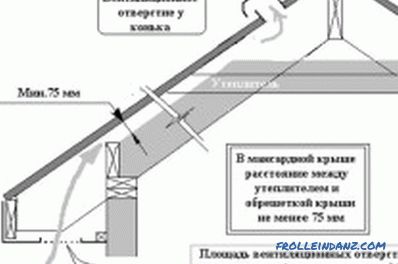

Crate Scheme the roofs.

- special metal studs that, thanks to their thread, securely fix the support bar (mauerlat);

- brackets and brackets for fixing rafters to the support bar;

- various fasteners (galvanized nails, screws and small diameter studs);

- drill;

- saw;

- hammer;

- tape measure;

- ax;

- plane;

- level or plumb.

The stages of the construction of the roof frame

The main stages of the construction of the roof frame for the house are as follows:

Mounting scheme shortened rafters to ridge rafter.

- Wood processing. Since you will not be able to process lumber in the future, this will be best done at the initial stage of construction. Process material with two compositions. The first, an antipyretic, is able to reduce the flammability of wood.The second, antiseptic, helps prevent rotting of wooden elements. Remember that after processing the lumber must be thoroughly dried.

- Install the power plate. Mauerlat is called a timber, which acts as a support for the entire structure of the frame. It must be laid directly on the bearing walls of the house. And its main function is the uniform distribution of the load associated with the weight of the roof.

- To install the support beam, it is necessary to build a solid concrete pavement around the perimeter of the entire building. After drying, the concrete screed on its surface must be laid in several layers of waterproofing material, roofing material is excellent for these purposes. Next, in the concrete blind area install special metal studs with a diameter of at least 10 mm. After that, the support bar "put on" the installed studs, for this it is necessary to pre-drill holes in it. Remember that the ends of the studs will have to protrude at least 10 mm. Subsequent fixation is carried out by means of nuts.

- Install rafters. Experts advise: if you work alone, then to facilitate the work it is best to collect rafters on the ground. If you have an assistant, then you can safely assemble the structure directly on the roof of the house. To begin with, it is necessary to make grooves for the installation of truss legs in the support bar. The distance between the grooves must be determined in advance, based on the dimensions of the structure itself, however, they should not be more than 1.5 m. Otherwise, the structure will have insufficient rigidity.

- Install the rafters from the front-end of the building. After that, you need to tighten the cord between the skates of the two end rafters. Thanks to this technique, it will be easy for you to orient yourself while exposing the vertical of the remaining intermediate rafters.

- Next, the truss legs must be inserted into the previously prepared slots. Fastening is carried out through the use of integrated mounting: transverse and longitudinal. Lateral mounting is carried out through the use of steel brackets, and longitudinal - through the use of special brackets, which securely fix the rafters to the power plate. During the installation of the rafters, make sure that they protrude approximately 40 cm beyond the perimeter of the building.

- Fix the lower part of the truss system, using for this purpose a harness - the base of the attic floor. If necessary, the harness can be extended with additional bars, laying them overlap.

- Between the rafters must be connected by two pairs of studs. The presence of two, not one, studs is due to the fact that when fixed with one fastener, the rafters will rotate around its axis.

- We give the structure greater rigidity and install an additional transverse beam. Now the rafters will externally resemble the shape of the letter A, this technique is relevant in cases where the distance between the walls is more than 6 m. The dimensions of the cross bar can have the following values: 50x150 or 50x100 mm. Fixation is carried out using screws.

- Install the ridge bar at the top of the rafter. If necessary, you can reinforce the top node with an additional crossbar.

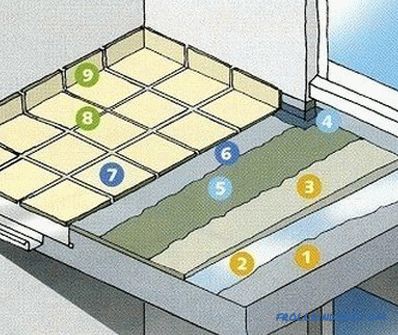

- After all the rafters have been erected, you can safely proceed to the crate and the lattice. To date, there are two options: thinned and solid, depending on what kind of roofing material you plan to use. Thinned crate is a horizontally packed bars on the rafters with a certain distance. Any roofing material of increased rigidity (slate, decking, etc.) can be laid on such a sheathing. With a continuous sheath, moisture-resistant plywood sheets are packed onto the surface of the rafters;

As you can see, the process of erecting and building a roof frame with your own hands is quite capacious. However, with careful preparation and knowledge of all the subtleties and nuances of the arrangement of roofs, you can easily carry out this work yourself.

Didn't find the answer in the article? More information on the topic:

-

How to make the floor on the balcony yourself?

Step by step instructions on how to make the floor on the balcony with your own hands. Useful tips and tricks, tools needed for the job. Optimal flooring material on the balcony.

-

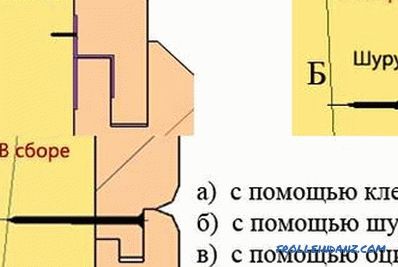

How to fix the wall panel correctly?

Instructions on how to fix the wall paneling. Basic tips and advice when working with different surfaces. The need to use crates. Performance of installation works.