How to make a table and will it work if you work on your own? Undoubtedly, it will turn out if you stock up on the necessary materials, show a little patience and spend a small amount of personal time.

If you want a beautiful, inexpensive, stylish, unusual table, then make it your own hands.

Making a table made of wood will be easier than ever.

Preparation for work

It is important to immediately determine the size of the structure. This parameter is influenced by the size of the room where the product will be used, and a number of other factors . For example, if for comfortable use 70 cm of space per person is required, then a table designed for four people may have dimensions of 1x1 m. If necessary, put the product to the wall, you can increase the dimensions along the length, for example, to 1.4 m, while reducing the width to 80 cm.

Wooden table design.

For spacious and large rooms, the dimensions of the structure must be increased, which will increase the number of people who can simultaneously use the table. As for the height of the object, it is selected based on the growth of family members. The best option is the height of 70-100 cm. In addition, care should be taken that after placing the table there is free space, which is especially important for the kitchen.

Separately, it is worth mentioning the material, since the durability and strength of the product, especially if it is a table made by own hands, depends on it. It is necessary to pay attention to the type of wood, its softness and hardness. There will be knife marks and other damage on soft rocks, even if the damage is not intentional. Softwoods include cedar, alder or aspen, and hardwoods such as elm, ash or oak.

If it is impossible to purchase or use wood, you can take laminated chipboard to make a table. It is worth noting that the thickness of the sheets should be more than 2 cm. Plywood is also suitable, only the specified materials should be pretreated with special tape or PVC.

To make the table yourself, you will need the following tools:

- Hacksaw.

- Grinding machine. Sandpaper is also suitable.

- Electric jigsaw.

- Planer.

- Boards 2-2.5 cm.

- Drill.

- Bolts.

- Milling machine.

- Brush.

- Varnish.

Making the design

Stages of manufacturing a wooden table.

To make a wood table, you will need legs. Their number, shape and size depend on the planned design. You can make a small table on one leg, but it must be strong enough to withstand the design. When using two legs, they should be made with a wide base to increase the footprint. The most popular design is a hand-made table with four legs, in this case the elements are placed at the corners of the table with their own hands. It is necessary to treat the manufacture of the legs with full responsibility, and their appearance should be good enough, since the wooden table itself will cover the tablecloth or other covering, and the legs will not.

As for the table top, it is possible to use a wooden massif or a laminated chipboard previously indicated for its manufacture. However, it should be remembered that the thickness of this element will be more than 2.5 cm. The table top can be given a different shape by limiting it to a simple rectangle or a more complex oval, for which it will be necessary to cut off the extra parts. The result of the work must be polished.

Before assembly, it is recommended to make all the parts to which the tabletop and the legs belong, after which they can be machined with a grinder, then varnished.

Only after the manufacture of these parts should begin to fix the legs. This work is done with the help of corners fastening the structure.

Thus, the construction of a tree with his own hands is not complicated. After making the product, you can paint it in the color you like, and after the material dries, the table will be ready for use with your own hands. It is important to fasten the parts securely, and make all the elements beautifully, so that the product does not disappoint its owners.

Didn't find the answer in the article? More information on the topic:

-

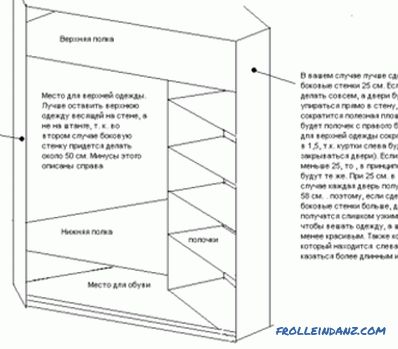

How to make a corner cupboard with your own hands

Instructions on how to make a corner cabinet with your own hands. What materials can be used? The complete process from cutting to closing edging. Features of the workflow.