Houses built of timber are characterized by excellent thermal insulation characteristics. They are able to keep warm for a long time, and in the summer heat - to create coolness. Timber belongs to materials that fully comply with environmental requirements, so a large number of people are looking for an answer to the question of how and how the log house is finished.

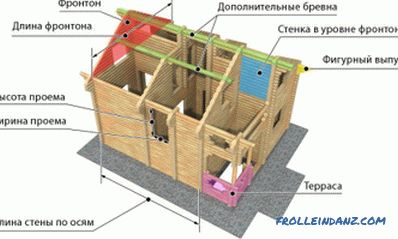

Scheme of a log house.

For the production of finishing works it is required to wait for a complete shrinkage at home. This usually refers to the exterior finish of a log house. It takes place over 2 years, the house gives final shrinkage after 5 years. Work on the interior can begin immediately, but it is necessary to consider some subtleties. Hard materials are not suitable for such work. After a complete shrinkage of a log house, the size of the walls sometimes decreases to 3 cm.

Some features of the finish

Basically, the log house looks great even without finishing. It will be quite enough to carry out the grinding work and cover the logs with antimicrobial coatings. They will be able to protect the walls of the frame from various mechanical effects and scratches. Such impregnations will protect the log house from being absorbed by the tree of all kinds of domestic smells.

Coatings are conditionally divided into two types:

- protective;

- tinting.

The first look creates a smooth surface, and the second - the desired shade. Before complete shrinkage, the log houses are finished using a variety of materials.

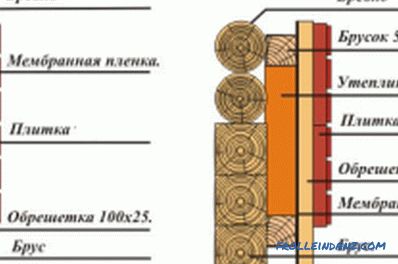

Scheme of the exterior finish of the log house.

Lining is considered to be one of the most popular materials used for finishing a log house. This material has excellent qualities, it is available in various shades and colors. The owner of the log house can only pick up the material in accordance with their requirements. Finishing in the frame clapboard can be carried out on the ceiling and walls of the house.

The interior decoration includes:

- floor;

- ceiling;

- doors;

- windows.

At the same time as finishing, all engineering work is done: electrical wiring is carried out, all communications are laid and necessary plumbing works are performed.

In addition to wall paneling, finishing in a log house can also be carried out with sheets of plasterboard followed by wallpapering.

Clapboards are called boards that have special grooves for joining. Due to this there is a tight connection. Virtually no gap between the boards is not formed. The surface is absolutely flat.

The material for lining is hardwood. One of the best is pine lining. It is divided into several classes:

- extra (most expensive);

- "C" - low cost.

Lining is mounted in two ways:

- open;

- hidden.

Scheme of interior finish of the log house.

Selection of fastening materials depends on the method of fastening. When using the open method, usually use self-tapping screws, easily twisted by a screwdriver. In the case of the use of the hidden method, brackets are used that are “shot” by the stapler. Attachment points remain invisible.

Finishing in a wooden house can be done in a block house. This material, which is a special, decorative lining. It is manufactured in width not exceeding 80 mm. Appearance of this material imitates the rounded log. This material is horizontal finish. The positive quality of the block house are grooves located on the inside. Thanks to them, good ventilation is provided.

To perform the finish, use a bar imitation.

This material resembles a block house. It differs only in its completely flat sides. This block house has a front side in the form of a truncated half-cone, and the back side is completely flat.

The exterior finish of the log is made of a variety of materials, wooden and artificial. For this purpose, apply:

- siding;

- artificial stone;

- stone panels;

- block house;

- lining;

- facing brick.

Practical recommendations

The frame can be painted. It will not be very expensive, but beautiful. Over the years, the exterior finish may change, which revives the beauty of the house. Its appearance becomes attractive again.

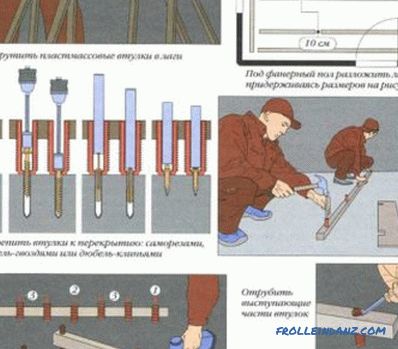

Tools for finishing a log house.

Basically, the exterior trim is made to protect against atmospheric agents. This is especially true of log. When it is built with high quality, its decoration turns into a decorative ornament. She creates an individual look.

The most frequently used siding for decoration. This material is not subject to rotting, it will never rust. Indoors there is free air circulation. The house gets excellent thermal insulation.

Lining is considered the cheapest and most affordable option. She performs interior decoration of the room.It looks great on the outside of the building.

Finishing of the log house inside the room is also made from sheets of drywall. This is probably the cheapest way.

An original “wet” lining is made. Today it is the most expensive option. Sometimes they use different panels for decoration, make a decorative crate. The most popular method of finishing a log house has become ordinary polishing followed by polishing. Tinting is done with special formulations that have protective properties. In addition, such compositions play a decorating role.

It must be said that the finishing works always require large monetary investments, therefore it is best to entrust such work to professionals who will carry out all the finishing works for a not very large fee. The main thing that these were true masters.

Required for work devices

Any finishing work can not be performed without having at hand the appropriate measuring tools:

- level;

- plumb;

- roulette;

- ruler;

- caliper.

The tape measure is necessary to measure the overall dimensions, it helps to determine the required amount of work. The future costs and the repair itself depend on the measurement accuracy.

Without a level it is difficult to determine the horizontal surface. It will help track the vertical installation of all parts of the house. With the help of a plumb line, the installation of vertical partitions inside the building is checked.

To work, you also need hand tools:

- trowel;

- trowel;

- trowel;

- rule;

- graters;

- brushes;

- rollers;

- buckets;

- hammer;

- mallet;

- screwdriver;

- wrenches.

The tools listed above are fully accessible and very easy to work with. They will help you quickly and accurately perform finishing work and decorate your home.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building with serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.