Often the basement of the house is too high, hence there are problems when entering the house, and then the presence of the porch will simply be an indispensable element of construction.

First of all, it is necessary that it be strong and proportionate to the house itself, otherwise the construction will look ugly and ridiculous. At present, the choice of finishing materials is simply huge, and the question of how the porch and the facade of the house will look like depends entirely on your imagination and material possibilities. The design and style of the porch can also be very diverse.

There are several types of shapes:

- in the shape of a trapezoid;

- in the shape of a rectangle;

- in the shape of a square;

- in the shape of a circle.

Semicircular concrete stairs

Semicircular concrete stairs

The design, in turn, can be:

- open;

- closed;

- made in the shape of a veranda.

The arrangement of the railing and steps can be either on the side or on the front side.

Of course, for the construction you can hire a specialized team of professional builders, but if this is not possible, then you will need to do it yourself.

Construction features

Laying of the foundation

Laying of the foundation

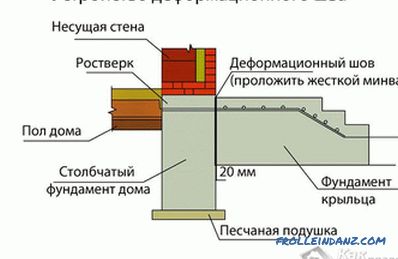

It is best to build a porch directly with home. In this case, they will have a common waterproofing and a common base. Waterproofing works are an obligatory stage necessary for the porch to serve you for a long time without any deformations. But, if simultaneous construction is impossible, it is necessary to know that the porch should be 5 cm below the door level. The presence of the steps depends entirely on the height of the entrance door.

The choice of site for a given building must meet, first of all, the requirement of convenience. It is necessary to use only good quality material that is moisture resistant, since the porch will be constantly exposed to temperature changes.

Reinforcement

Reinforcement

At the beginning the landlord must decide on the main stages of construction:

- Preparation Stage. There is a site preparation for construction, during which the dimensions are calculated;

- Basic. Its essence lies in the manufacture, installation and completion of formwork;

- The final - concrete installation.

Territory preparation and calculations

Clearing the area for the porch

Clearing the area for the porch

First you need to completely clear the area at the place of the future porch, remove the old one, if it was there. For work related to the foundation, dig a hole. Its depth is 20-30 cm, width — more than the size of the entire site by 2.5 cm.

Next, a layer of rubble is filled up, then a layer of raw sand. It is necessary that the cavities in the rubble be filled with sand.

When calculating the required dimensions, you need to start from the distance from the ground to the bottom of the threshold. The resulting figure will be considered height. Steps should be an average of 15 cm wider than the door. In order to make the exit from the house safe, the upper step should have a meter width.

To calculate the height of an individual step, the height of the porch is divided by the number of steps to be made.

Work with formwork

Manufacturing formwork

Manufacturing formwork

After all the necessary calculations have been made formwork, the height of which should be more than 30 cm in height of the porch itself, since it will go to the ground. It is possible that the formwork was 20 cm higher, but this is only if the soil is strong.

It is necessary to draw the risers and treads at an angle of 90 o . Then the ground and treads are drawn with a slope of 6 mm and a depth of 30 cm of water flow. After that, the risers are drawn. Their slope is 15 o . It is necessary to attach stiffening ribs to the sides of the formwork. Next, retreat from the wall of the building by 1 cm and assemble the prepared shields. Stakes are driven to a depth of 25 cm. Their distance from the excavation is 45 cm. Struts are placed between the formwork and stakes, the base is covered by 10 cm and tamped down. Boards are cut to the size of the risers, and boards are nailed to the formwork. To do this, you will need clusters with a double cap.

Concreting

Concreting the porch

Concreting the porch

Finally, the foundation of the house is covered with roofing felt, and then apply sealant to create a temperature weld. From the inside, the formwork is coated with grease to avoid adhesion of concrete to the structure.

It is best to concrete the porch immediately from the tray. It is more convenient if the concrete mixer is located directly near the porch. Laying start from the bottom step, moving up.

Fixing the formwork with additional supports will help prevent its form under pressure from concrete. It is necessary to apply a large amount of concrete in order to avoid voids and holes.After finishing the concrete surface, it is necessary to let it stand for a week, after which the formwork can be removed.

Video

Photo

Porch made of concrete and brick

Porch made of concrete and brick

Installation of porch formwork

Installation of porch formwork

Concrete porch with railings

Concrete porch with railings

Concrete porch with columns

Concrete porch with columns

Trapezoid concrete porch

Trapezoid concrete porch