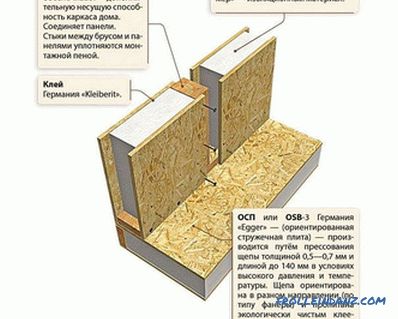

CIP panel is a building material inside which there is a layer of insulation, and the outer part is a layer of OSB.

Insulators

Inside the panel there can be different types of insulators, each of which has its advantages and disadvantages:

- Polyfoam (durable and environmentally friendly, waterproof, resistant to exposure to UV rays, but not resistant to fire).

- Mineral wool (almost does not burn, but at the same time does not have a harmful effect on health, is resistant to external factors, except water and moisture).

- Polyurethane foam (practically does not conduct heat, but burns quickly).

Assembly scheme of CIP panels

Assembly scheme of CIP panels

The panel can be of different thickness, which directly depends on thickness of insulation used. Standard dimensions of SIP panel (H * W * D): 174 * 1250 * 2500.

For the construction of walls of houses often use material coated with OSB plates. Moreover, there are 4 types of OSB plates, which differ in terms of strength and moisture resistance:

- 1 - First class slabs are the least expensive, but are not suitable for mounting parts that will experience severe stress. The moisture resistance of these plates is also low.

- 2 - The moisture resistance of these plates is also low, but the strength is much higher compared to the first class. In the construction of houses such panels can only be used for the installation of internal structures.

- 3 - Optimum class of slabs for building houses. They are ideal for the construction of facades and for internal partitions. During the construction of small low-rise buildings, they can be used even in the construction of floors and roofs.

- 4 - Durable and moisture-resistant material that is suitable for the construction of houses in difficult conditions with regard to the load and humidity.

Advantages of houses from CIP panels

Thanks to the following advantages, the construction of houses from CIP panels is gaining popularity:

- Saving on the foundation, due to the small weight of panels.

- Cost optimization, due to the low cost of the material relative to other types of building materials.

- Easy installation, due to the castle assembly, evenness and large area of the panels.

- Exterior and interior finish are also facilitated.

Disadvantages

- Pillows based on polystyrene foam and mineral wool are not as durable as polystyrene-based panels. Over time, the useful properties of vulture panels are reduced.

- It is necessary to provide high-quality ventilation in the houses.

Building project

House box - scheme

House box - scheme

Buildings from CIP panels are built according to the finished project, supplied with calculations and drawings. The finished project can be ordered in a specialized company, in the same place you can order the construction of the house itself or rely on your own strength.

Then you should order the required number of CIP panels, preferably with a small margin. Do not forget about the various structural elements and supporting materials. After delivery to the site, all elements are checked for compliance with the characteristics, in particular, integrity, size, evenness.

Assembly Procedure

The sip panels are lightweight, so when installing the panels you will not need the help of heavy construction equipment.

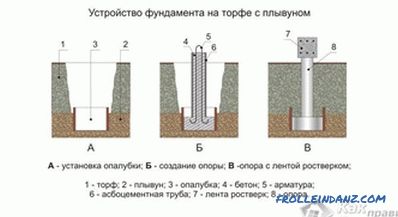

| First, proceed to the installation of the foundation. For houses made of CIP panels, a screw foundation is optimally suited. But the final decision on the type of foundation is made depending on the characteristics of the soil, terrain, and the wiring of communications (water, electricity, heating) must be made before the foundation is laid, laying down the structural elements. Having completed the construction of the foundation, it is necessary to make a strapping from a wooden support beam. Having checked all the parameters with a level, having set corners, make holes in the concrete surface of the foundation with a perforator and fix the timber with 12 mm anchors at a distance of 1-2 m from the adjacent anchorages. There must be at least 3 fasteners per beam. If a grillage is made of a wooden bar, it is necessary to tighten its structural elements with M10 studs at a distance of 30 cm from each pile. |

| In this case, irregularities may form, which can be eliminated with a planer. |

| On the piles, under the grillage, you must put pieces of roofing material. Then the grillage is attached to the piles with M10 studs. |

| Under the nuts and washers make grooves. |

| After installation, the timber is processed by working off or bitumen mastic. Then, in order to protect wooden elements from damage, the bottom of the floor panels is treated with the same substance. |

| Building a house begins with laying the first floor - the first panel is placed on the harness and caught with screws to the harness. |

| The end of the panel is moistened with water, foamed. |

| Install the connecting beam (log). |

| Fix it with self-tapping screws. |

| The outer ends of the panels after the assembly of the first overlap are moistened with water, sealed and set the board - fixed with self-tapping screws. |

| Before installing the wall panels, you must fasten the embedded board. It is treated with foam and set around the perimeter of the ceiling. |

| Fix it with 280 mm self-tapping screws. |

| Then the first wall panel is mounted. From two sides the panel is fixed with screws to the embedded board. |

| The verticality of the installation should be adjusted to the level. Before installing the second wall panel, you must fasten the connecting bar. Joints necessarily propenyvayut. The panel itself is attached to the bar with self-tapping screws. |

| The corner panels are tied together with 240 mm Spax self-tapping screws or "grouse" in 15 cm increments. Interroom partitions are installed in the same way. |

| After the interior partitions are assembled, they start installation of the floor slab - install the beams, creating a temporary fastening with self-tapping screws. In the staircase set support beam. |

| Sheets of OSB are laid on the beams and fixed according to the instructions. |

| Further assembly of the house is carried out similarly to the first floor. |

| The ends of the walls adjacent to the gables should be sawn at an angle. Then install the beams on the gables. Beams must also be cut down, according to the slope of the roof. |

| Install the ridge bar. |

| Cut it out at the required angle. |

| The ends of the gables are covered with sealing material before laying the panels. |

| After the walls have been erected and the beams are installed, the installation of the roof proceeds. This is done according to the drawings, given the labeling on the panels. If the removal of the roof is small, then first the first panel with a length slightly more than the width of one slope of the roof is laid on the gable, the second one is positioned so that it rests with the long side on the gable, and the short one on the first panel. If there is a significant removal of the roof, then the extreme row consists of small panels, between which additional bars are inserted, and the corner panel should consist of two triangles in order to insert the beam diagonally. |

| The panels are fastened to each other with a connecting rod, and the ends are closed with a board. On the ridge panels fasten with each other. |

Thus, houses are assembled from SIP panels. All work (depending on the size of the house) is carried out in a matter of days.