The block house appeared not so long ago - the 90s of the XX century. This lumber is similar in construction to the clapboard, but its outer part has a convex shape. This feature allows the lining to create a surface that simulates a log house. Products are processed on milling machines for the manufacture of tongue and groove, so the installation is easy to perform independently. The main raw material for the production of finishing materials are coniferous trees: larch, pine, cedar, spruce. An alternative to an expensive block house made of natural wood are products from polymers and metal. They mimic realistically wooden veneer, while resistant to moisture and microorganisms.

How to choose high-quality lumber

Extra

Extra

The wooden block house is used for internal and exterior home decoration. Among its advantages:

- environmental friendliness;

- attractive appearance;

- vapor permeability.

Depending on the placement of the material, the requirements for it change. For interior design, boards are taken of a thickness of 20-24 mm and a width of 95-105 mm, varieties "Extra" or A, which are distinguished by the absence of knots and defects. Exterior finish requires a more durable material, the thickness of the boards is 40-45 mm, width - 140-200 mm. More affordable varieties will fit here: AB or B, but there should be no mold, cracks and knots on the material.

Installation of a wooden house block

To install the finishing material, you need a screwdriver and a hacksaw to cut the boards. Fixation is carried out in two ways: by self-tapping screws and klyimer.

Fastening with a self-tapping screw

Fastening with a self-tapping screw

Using kleimer creates a reliable fastening, self-tapping screw or a nail can damage the wood , and a galvanized steel clip gently fixes the edge of the groove.

Clamping

Clamping

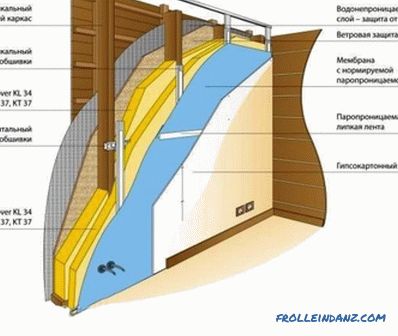

The exterior finish is not fixed on the wall, but on a wooden frame timber. Between the block house and the surface lay a multilayer cake:

- vapor-permeable membrane;

- crate;

- insulation;

- waterproofing;

- block house.

Before mounting the board is treated with antiseptic and antipyrine. Mineral wool is recommended as a heater, which is close to wood in terms of vapor permeability and does not burn. The lining is performed as follows:

- A vapor barrier film is attached to the wall with brackets, at the joints it is glued with aluminum tape.

- Fastening of the batten from a bar equal to the thickness of the insulation is performed. The step of an obreshetka of 50-60 cm. Pre-wood is treated with an antiseptic.

- Mineral wool is laid between the guides.

- The insulation is covered with plastic wrap to protect from moisture.

- The second layer of the batten is stuffed, to which the block house is fastened with klyimers, the products are interconnected by inserting a tenon into the groove. When using self-tapping screws, the fastener is screwed into the groove, the fixing pitch is 40 cm.

Mounting layout of the skin with insulation

Mounting layout of the skin with insulation

Installation of the material starts from the bottom, when installed outside the board, they are placed with the groove downwards, which prevents water from entering the joints.

External corners are decorated with a special decorative element. For internal joining on the boards, sawn-offs are made at an angle of 45º. Window and doorways are decorated with platbands.

Finishing of external corners and window openings

Finishing of external corners and window openings

Variety of materials

Among materials from which make facing, metal and polyvinyl chloride. The metal block house is produced as an imitation of rounded logs, while it is superior to a wood product in strength, fire safety and moisture resistance. With numerous advantages, lining loses in appearance analogue of lumber.

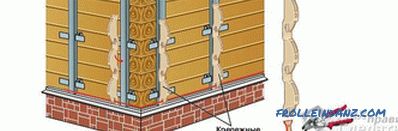

Mounting the metal house block

Mounting the metal house block

The metal house block is mounted on a galvanized profile. Unlike wood, a steel sheet coated with a layer of polyester is insensitive to moisture and does not require antiseptic treatment. The thickness of the material is only 0.5 mm, and the width is 210 mm. The weight of the metal house block is significantly less than that of wooden boards and does not exert a significant load on the foundation. Guides for horizontal mounting finishes are installed vertically. For insulation between the cladding and the wall is placed insulation - mineral wool or extruded polystyrene foam. When fastening the panels, the screws are not fully screwed in so that the material can move during thermal expansion. For decoration facing used internal and external area, the docking plate.

Mounting the vinyl block of the house

Mounting the vinyl block of the house

The vinyl block of the house has an affordable price and a variety of colors. The panels are resistant to temperature changes, the action of microorganisms and moisture.They are easily mounted and serve up to 50 years. Installation is also carried out on the batten. When mounting the panels between them, gaps of 1-2 mm are left to expand when heated.

Some types of vinyl house block are completed with fixing profiles style, the work does not require serious training and special knowledge, it can be done on its own, asking for the help of a partner.

Some types of vinyl house block are completed with fixing profiles style, the work does not require serious training and special knowledge, it can be done on its own, asking for the help of a partner.

Video

For instructions on external house cladding, see below: