Almost any topcoat needs a smooth surface, and you can perform leveling work in several ways. The easiest way to level the floor with plywood, by the way, this method will not be so expensive.

Leveling the floor with plywood is one of the cheapest ways to finish the floor, but also very high quality.

In order to get the perfect effect, it is necessary to make a complete dismantling of the floors, this will allow the most efficient installation of the new coating. Leveling the floor with plywood can be done with or without lags, but the latter option will be less labor-intensive.

Required tools and materials

- plywood;

- primer;

- roller;

- bitumen mastic;

- needle roller;

- self-tapping screws;

- perforator;

- sandpaper.

Leveling the base with plywood without applying lag

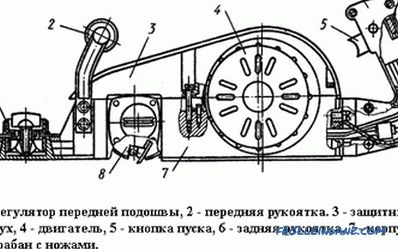

Tools for laying plywood.

Before leveling the floor with the base of the wooden floor, it should be noted that the surface will eventually turn out to be flat but not aligned horizontally. However, this is not always required.

If it is necessary to level the concrete floor, then it should be noted that immediately after laying the screed, it is not necessary to begin work. In addition, it is necessary to analyze the moisture level of the surface, in the process of which you should use a piece of polyethylene, which must be laid on the floor and pressed into bars along the entire perimeter of the room. After 4 days, you need to check if there is condensate under the base of the film. If it is absent, then you can begin to work on the alignment of the floor.

The process must begin with cutting the material, the elements of which are to be expanded in the room. This will help prepare the elements that will form near the communications, arches, openings, corners, etc.

Plywood is realized in the form of square sheets with a side equal to 125 cm. Material of standard sizes must be cut into 4 squares. As soon as a cut has been made, it should be checked whether the ends of the blanks have been damaged.

Sheets should not be laid excessively tightly to each other, this is due to the fact that the material tends to deform and also reacts to periodic changes in temperature and humidity.

Floor covering with plywood.

If you close the sheets close, over time the floor will begin to change its linear dimensions and creak. Thus, the gap between the sheets should be equal to the limit of 5-10 mm. When leveling the floor with plywood, it is necessary to leave a gap between the walls and the floor, which should be 10-20 mm. These grooves are necessary for free air circulation.

Sheets should be displaced relative to each other when laying, avoiding the formation of a joint between four corners. It is preferable to first lay the canvases without reinforcing them and number them - this will allow us to remember the order of installation. If necessary, you can draw a pattern of stacking, making notes on the draft coating.

In the next step, you can prepare the surface by removing dust from the floor. Now you can cover the surface with a primer, which may be a primer. It can be prepared by mixing glue intended for plywood, solvent (gasoline) and bitumen mastic. The resulting solution has good absorption into the concrete base. This process will ensure the safety and durability of the cement floor, increase the adhesion of plywood sheets to the surface. Apply primer to the floor with a roller or a wide brush. Once the base is dry, it is permissible to begin the process of leveling the floor.

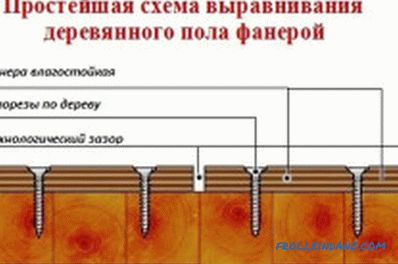

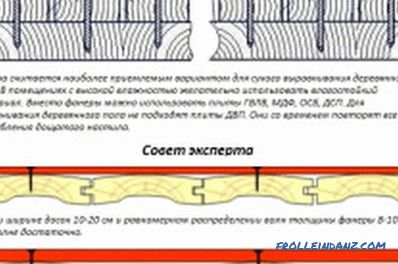

The scheme of leveling the wooden floor with plywood.

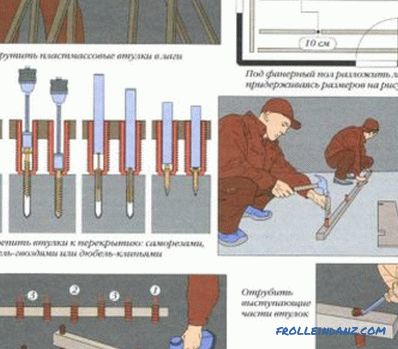

Floor correction with plywood without lag can be carried out using glue. As it can be used and bitumen mastic. The composition should be applied in a layer whose thickness is 2 mm. Uniform distribution of the composition will contribute to the needle roller. Plywood sheets to the surface of the floor should be fixed not only by glue, but also mechanically. Fasteners can make screws or anchor bolts. Fasteners must be selected taking into account that its length was 3 times the thickness of the plywood. Leveling the floor should be done by installing fasteners at a distance of 20 cm.

After the sheet is laid, it is necessary to drill it and make a hole in the base of the screed to the required thickness and depth. Using a large drill bit, you need to countersink a hole in the sheet, which will subsequently completely drown the fasteners. After the alignment process is completed, the sheets can be sanded by applying sandpaper, a sander will help to speed up these works.

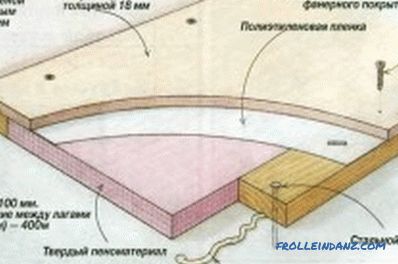

Layout of plywood on the plank floor.

Leveling the floor with plywood can be done using an adjustable method. To do this, you have to drill the holes according to the scheme, then attach the sheet to the floor surface and equip the holes in the base. Anchors with nuts and washers should be installed in the holes. The location of the nuts can be set using a laser level. By installing anchors on the floor surface and determining the level, you can mount the plywood, fixing everything on top with nuts and washers. The rods will have residues to be disposed of. This method involves laying the second layer of plywood. Installation must be overlapped so that the joints of the lower layer are located in the center of the plates of the second layer.

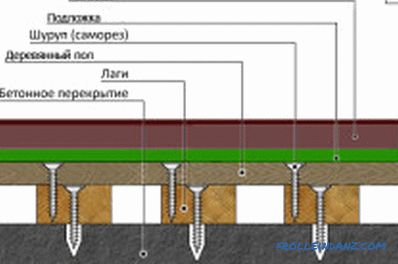

Leveling the base with plywood over lags

Even if the surface is equalized with plywood without a lag, it does provide a less durable finish than with a lag. In order to ensure the alignment of the surface horizontally, you can first lay logs on the rough base, which are to be fixed with anchors, but first you need to lay a substrate of elements made of fiberboard on the floor. A pitch equal to 60 cm is used as the optimal distance between the lags. A higher degree of strength will be provided by the grid, which must be formed from the lag. Across the main lag you need to put trimming, observing the level.

Layout of plywood on wooden logs.

If lags are supposed to be mounted in the living space, their laying should be done perpendicular to the direction of light.

Lags can also be laid on beams, which will increase the rigidity of the floor structure, extending its lifespan.

If you wish to level the floor with lower labor costs, you can initially install two beacon lags, which should be removed a considerable distance from each other. Between beacon lags, the rest of the lag is to be assembled, taking the level of the former as a basis.

Before the final laying of sheets, you need to determine the points at which the fasteners are to be installed. After the marks you can drill holes, the diameter of which should not be larger than the cap of the screws. Holes should be separated from each other at a distance of 10-30 cm. In the end, the sheet of plywood must be strengthened with screws. It is possible to level a floor in this way, laying plywood in several layers. After you have managed to level the floor with the first layer of plywood, you need to seal the gaps, during which it is recommended to apply elastic mastic, which is pressed into the seam, and then rubbed with a spatula.

Floor correction with plywood without a lag is much easier, but then it will not be possible to achieve horizontal alignment of the surface. But using a lag involves raising the floor height by a few centimeters.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building in case of serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.