Intrusive insects prevent live and sleep at night in the warm season. They fly into the house through open windows. Despite the presence of a large number of special sprays and electric mosquito catchers, only the mosquito net can significantly reduce the number of insects. Today, carrying out the replacement of windows, you can additionally order this item that costs money. How to solve the problem in the budget option? In fact, everything is very simple, as the mosquito net is mounted very quickly with the hands of the available materials.

Protective meshes

Mosquitoes on stocks

Mosquitoes on stocks

Before heading to the hardware store for all the necessary components, you should decide on the type of grid. They all differ in different parameters:

- According to the type of attachment: hooks, velcro, pins and Z-shaped brackets.

- By type of opening: stationary, removable, movable and rolled.

- By the presence of the frame: frame and frameless.

- By fastening: internal and external.

The frame structure

The frame structure

Each of these types has its own advantages and features, but together with them and disadvantages. All this is important to take into account in order to make the right choice and not waste your money. Particular attention is paid to the method of attachment, so let's see: what are the pros and cons?

- The frame is very rigid, because it is made of metal with a mesh canvas. It can be installed on plastic and wooden windows from any side.

- Sliding mounting is only suitable for aluminum windows, since sliding doors will be used.

- Mosquito net on magnets is a very relevant option for those who want to quickly get rid of insects. It is mounted on the windows and on the door. In the latter case, you can not worry about the permeability, as the curtains can easily open and close instantly.

- Rolled nets will allow you to effectively combat mosquitoes. The material is easily folded and unfolded from the cassette placed above the window.

- Simple stickies are also easily fixed and removed. In this case, the grid can be washed at any time in a washing machine.

On magnets

On magnets

Mosquito nets are installed not only on windows, but and on the door, because mosquitoes and midges also penetrate through them.

Rolling mosquito

Rolling mosquito

On Velcro

On Velcro

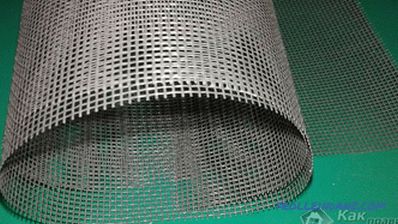

Canvas selection

The main element of any mosquito net is the canvas. You can buy it at any hardware store on the footage or on a roll (approximately 30 m). If you need to make only a couple of nets, then it is better not to spend money and buy the required number of meters. For more protective nets, it’s worth comparing prices: they can vary per square and running meters.

Canvas in a roll

Canvas in a roll

When it comes to quality, it is important to consider several parameters:

- cell size;

- web thickness;

- material type;

- strength.

The strength parameter is very important for creating an “anti-cat” grid, since it must withstand all “attacks” of pets. The most ideal option for this will be polyester with special impregnation. Additional fasteners are also needed. It is especially important to install such mosquito nets on the balcony.

Types of mosquito nets

Types of mosquito nets

When determining the size of the cells, consider the size of insects in areas that require additional protection. The minimum size of the cross section is 0.25 * 1 mm. Such a grid can become a reliable protector not only from mosquitoes and flies, but even from sand, poplar fluff and dust. To protect windows and premises from rain, experts recommend a section of 1 * 1 mm.

Having decided on materials and having made necessary purchases, it is possible to start production. How to make a mosquito net on a window frame and frameless type, will be discussed below. Protection will be the same functional as with the production.

The material of which it is made will be responsible for the quality of the protective mesh. Recently, the most popular fiberglass with a polymer coating.

Making a frameless mesh

Frameless mesh

Frameless mesh

This is the easiest and the budget option, which will make a removable mosquito net, spending small funds. The easiest way to make the protection stationary - just stick the canvas to the window frame. To make it better fixed at the edges, a tape of material with high adhesion properties is sewn on. When it comes to wooden windows, the usual clerical buttons can act as additional fasteners. There is one significant drawback - such a mesh can not be removed for washing.

It is better to put a little more money and effort into getting universal protection. It is about a grid on a flypaper. To make it yourself, you will need the following materials:

- anti-mosquito material by window size;

- adhesive tape (burdock - one side with a nap, the other with hooks);

- construction glue.

Stitch velcro to the grid

Stitch velcro to the grid

Measurements are performed on the inside (opening) part of the window with a stock of 1 cm on each side. This size is necessary for fixing the future mosquito net. One part of the adhesive tape is fixed around the perimeter of the window with the help of construction glue (for example, Titan) or a simple double-sided tape. The second is sewn around the entire perimeter of the grid. When everything is ready and the glue is completely dry - you can fix the protective sheet.

The entire work process takes a maximum of 2 hours, and as a result, everyone gets reliable protection from insects.

Before sticking the adhesive to plastic, it should be thoroughly cleaned and degreased with alcohol.

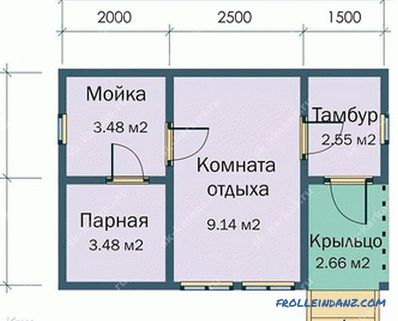

Making a mesh of a frame type

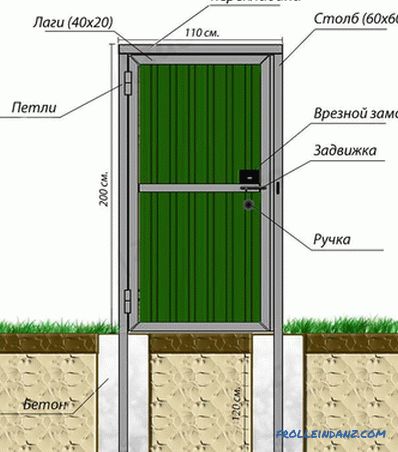

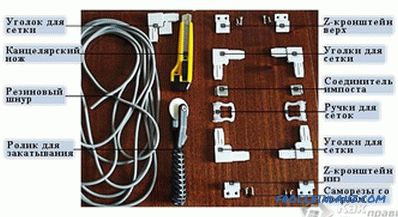

In contrast to the previous method, it is somewhat more difficult, but everyone can cope with it. It should be noted that this option is suitable for the manufacture of mosquito nets on the door. So, for the installation of the frame, you will need the following components:

- cable channel of rectangular section 15 * 10 cm (length is determined independently based on the external parameters of the frame where the frame will be fixed);

- metal corners 10 mm - 4 pcs. ;

- rivets - 16 pcs. ;

- thin nylon mesh;

- construction glue.

Tools:

- knife;

- sharpening bar;

- pencil;

- scissors;

- roulette.

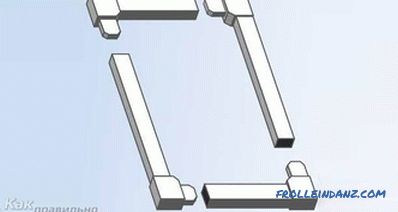

Assembling the frame from the profile

Assembling the frame from the profile

Go to the construction of the structure:

- Measure the outside of the window opening. Based on the data obtained, a frame will be made.

- We mark the length and width on the plastic box.

- With a knife, cut off the vertical and horizontal parts at an angle of 45 °. The cut points are carefully ground with a grinding block.

- We assemble the structure: we fix the corners with special connecting metal corners with rivets (nuts and screws will also fit).

- We apply a mosquito net with an allowance of 2 cm on each side.

- In the upper part, we clamp the canvas with the cover of the plastic cable channel. In the process of snapping, we change the long and short sides. For reliability, some places glue glue.

- Excess tissue is cut with scissors.

The finished mosquito net is installed in the window opening using Z-shaped brackets.

And this is how the grid from the special profile is assembled:

What you need

What you need

Details are cut

Details are cut

Restoration of mosquito nets

An equally important process is the restoration, which includes such main steps:

- Removing the frame from the brackets.

- Dust and dirt cleaning.

- Removal of damaged nylon.

- Installing the repaired mesh in the window opening.

The sealing cord

The sealing cord

is removed before replacing any element in the design, It is necessary to pay attention to how it is fixed and whether it should be removed. Most of the elements on the mosquito net from the manufacturer are fixed with a special sealing cord. If it is carefully removed, the holders can be easily removed.

Cord installation and trimming after restoration

Cord installation and trimming after restoration

All repairs are done very carefully. It is important to remember that you are working with a fragile structure.

As you can see, in order to make a mosquito net with your own hands, you have to spend 2 or even 3 times less than when ordering a similar design from the manufacturer. In addition, the installation process is quite simple, does not require special knowledge and equipment.

Video

See below for instructions on making mosquito nets for plastic windows:

You can also do without making a frame if you act like this:

See also:

- How to measure the mosquito net.

- Installation of a mosquito door.

- Installation of plastic windows.