Without the caulking of a log house, a wooden structure cannot effectively hold heat, even if the logs are fitted very tightly. This is especially true for such facilities as the bath, where other types of insulation is usually not provided. Caulk bath with special tools, caulks, and as a sealer use several different materials.

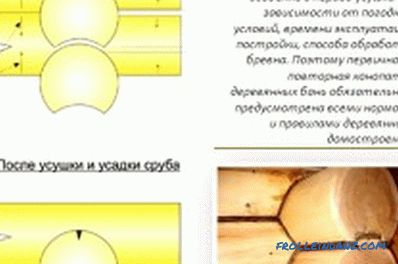

A scheme for embedding cracks and crevices between individual bars or logs.

Selection and preparation of material

For caulking a log house, along with long-proven tow, hemp, felt and moss, modern materials are increasingly being used: flax cotton and jute. All of them have their own advantages, but they require some preparation. This is due to the fact that natural seals are prone to rotting and are afraid of insect pests. Competent and timely processing of insulation will help to avoid this problem and extend its service life several times.

Moss is probably the oldest logging compactor, since they have been caulking baths since time immemorial. And now in some regions the use of this material is the cheapest way to warm log buildings. The moss must be properly dried: if the moss is overdried, it will crumble in the hands and will not get stuck in the cracks, but not dry enough will start to rot itself and contribute to the rotting of the log house.

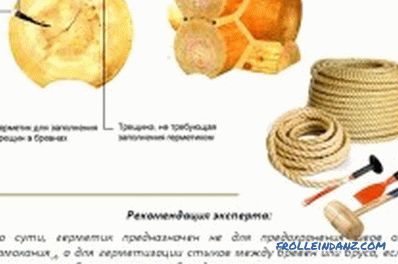

Types of materials for bath caulks.

Felt and tow have more advantages than moss, but moths love these materials too much. To protect the insulation from insects, it should be soaked with formalin solution and dry well.

Lnovatin and jute are made on the basis of natural components, therefore they are environmentally friendly materials. Thanks to modern technology, these seals are more convenient to use, resistant to weathering, and not damaged by insects. The cost of such materials is higher than tow or felt, but the service life is much longer. In addition, they do not require preliminary preparation, and therefore can immediately be used for caulking.

The process of compaction of a log house

Without adequate experience, making the caulking of a log is hard enough, because this process requires not only accuracy and patience, but also skill. And yet, it is easier to pierce a bath than a house, and therefore you can do without professionals. First you need to prepare the tools:

Sealants for a log of a log.

- road builder;

- rubber mallet;

- 20 mm chisel;

- set of caulking tools;

- hammer.

For high-quality insulation, it is necessary to caulk a bath 2 times, immediately after assembly, and approximately one year after a partial shrinkage of the structure. Full shrinkage occurs after 5 years, and then you can make a log caulk again, securing the effect of thermal insulation. 2 methods of caulking are applied: "stretching" and "into a set"; the first is used if the gaps between the logs are narrow and shallow, and in the presence of large voids and gaps the second method is more justified.

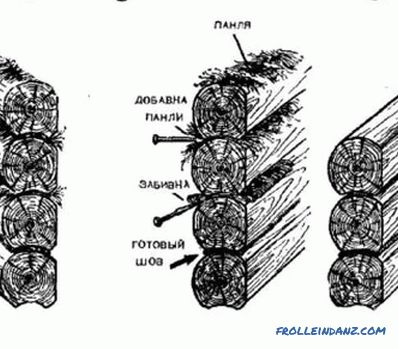

So, with a caulking iron "in stretching", a sealant tape is applied along the groove, and then pushed with a spatula inward so that an edge about 5 cm wide remains outside. to the groove and tamped with a chisel-chisel. The material should be evenly distributed between the logs, without lumps and hanging edges. If the piece of material ends, the next one is attached slightly overlapped to eliminate the slightest gaps.

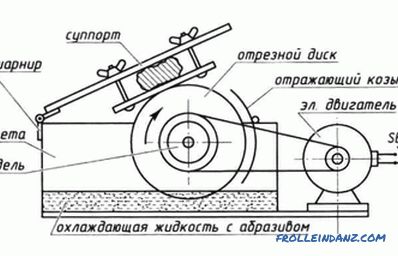

Primary and secondary log caulking tools.

If caulking "into the set" is used, make strands from the compactor and wind them into a ball. Then the strand is unwound of the desired length, rolled up in a loop and pushed into the gap with the help of a chisel: first, the voids are filled at the top and then at the bottom of each slot. The deeper the gaps between the logs, the more loops will be needed. The grooves should be clogged very tightly and carefully, and in order to have a more attractive appearance after the caulking of the walls of the bath, it is recommended that the seams be sealed with a road builder.

Regardless of the method, it is necessary to caulk a bath in a circle, starting from the lower grooves. If you seal each wall separately, the frame may twist. In addition, the sealing of the joints helps to raise the bath frame by a few centimeters, so the interior should be done after the completion of the thermal insulation work. For the same reason, you need to free up space around the chimney in the ceiling and roof of the bath, temporarily removing fasteners.

The caulking of the bath can be alleviated even during the assembly of the log house: it is necessary to immediately lay insulation between the logs, leaving 4-5 cm on each side.

This simple guide to warming a log house will help you choose the right materials and do the caulking on your own.Even if something does not turn out too neatly, you can correct the flaws later, when the bath shrinks. Having coped with such work once, the second time you can do everything much better and faster.

Didn't find the answer in the article? More information on the topic:

-

How to handle a tree in the bath?

What is the way to process a tree in a bathhouse so that it lasts longer, and it is comfortable and pleasant to be in it? We will try to consider the main features and nuances.

-

Tool for caulking the house from a bar

The caulk of the house from a bar protects it from external influences. For caulking iron, felt, moss, jute, hemp and tow are used. Plugging the gaps between the logs can be 2 ways: stretching or in the set.

-

Why do we need wood treatment with wood stain and varnish?

The rules for processing wood stain and varnish. Preparation of wooden surfaces for processing. Brief description of the main types of stains and varnishes for wood. Processing technology and the right tool.