Wooden houses are always very popular, especially for those who want to build their suburban housing. The material is environmentally friendly, affordable. But the main thing is that the timber is convenient because even not very experienced builders can build a house from it. The work is quite realistic for 2 people to do.

The material of the house from a bar is ecological and affordable.

How to build a house from a bar: a step-by-step instruction

The work begins with the design, it is necessary to designate heating and ventilation systems and the layout of the rooms. For example, in order to make it easier to make communications wiring, rooms such as a bathroom, kitchen, bathroom, it is desirable to be located close to each other.

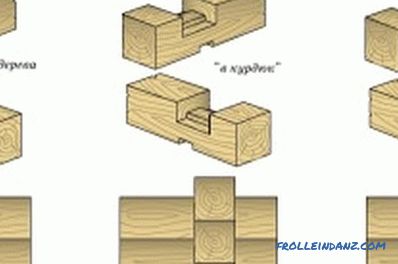

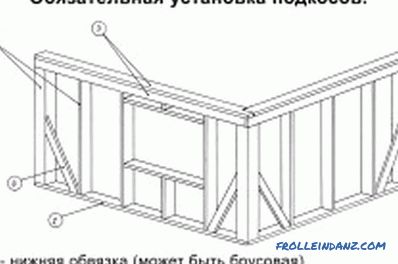

Principles of the organization of corners of a house from a bar with the rest.

Tools and materials for building a house from a bar:

- cant in the right quantity;

- ax;

- chainsaw;

- electric planer;

- drill, drill;

- sledgehammer;

- tape measure, level;

- nails, self-tapping screws;

- construction corner;

- compactor (moss, felt, jute fiber);

- insulation;

- roofing material;

- wood preservative.

Material calculation

Scheme of the house from a bar.

If you decide to build a house yourself, you will have to perform the calculation of the beam. To calculate the material on the walls, do the following:

- measure the perimeter of the house;

- multiply the perimeter by the height of the floor of the building;

- multiply this figure by the thickness of the timber that plan to use in work;

- so you will know the number of cubes that you need to build the 1st floor.

If, besides the external walls, there are internal partitions, this should be taken into account. If required, you can calculate the timber not only in cubic meters, but also in pieces. For this, the volume divided by the volume of a unit of material.

So, how to build a house out of a bar? It is desirable to sort the timber before work. Then touch. Then the bars are faced, customized to the desired length. Perform markup. They make grooves and spikes, prepare pins and holes for them. Based on the markup, lay the boards on the walls for which they are prepared.

Do not wait until the bar dries, process it raw and in the process of laying it into the wall.

The material should dry in the wall.

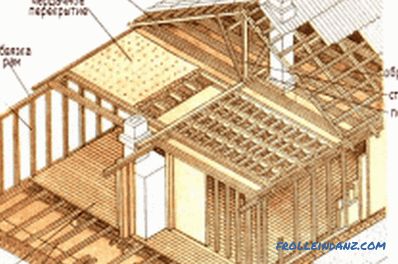

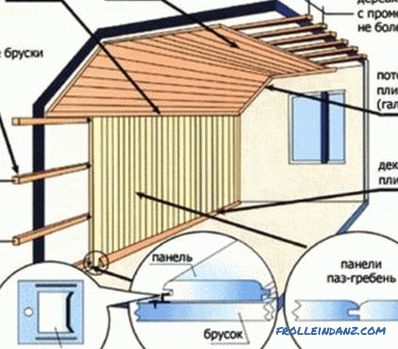

Scheme for assembling the walls of a frame house.

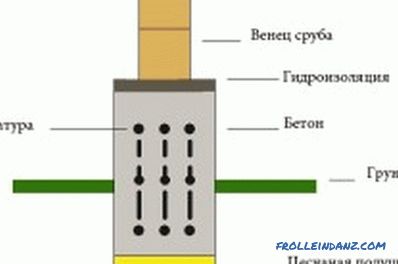

First you need to build a foundation. In this case, it is possible to make a shallow-tape foundation or a pile foundation. The choice will depend on the characteristics of the soil and the future weight of the structure. Once the foundation reaches the desired strength, you can begin laying the first crown of the structure. The first crown is a kind of contour that can withstand the greatest loads and is most susceptible to moisture. Experts advise between the foundation and the first crown to lay a larch wedding board, thereby creating a protective buffer. In addition, when repairing the lower part of the frame, it is easier to replace the board, and not the crown. The optimum thickness of the board is 50 mm. It must be treated with antiseptic.

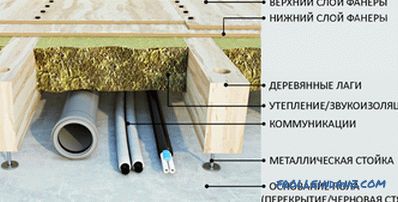

On the other side of the foundation on which the board will be laid, lay 2 layers of roofing material (waterproofing). The corner joint for the first crown is half a bar. Lags for the floor on the 1st floor are pierced into this or the 2nd crown. Or use a special fastener for timber.

The technology of assembling a house from a bar

The foundation scheme for a house from a bar.

The assembly of the house consists of a stonework laying, in which each successive timber is mounted after laying the underlying. Between the crowns put jute, designed to seal the joints of honey with them. If you work with a material of natural moisture, then every 2 crowns are staggered connected with dowels from a bar. They give the wall rigidity and ensure the preservation of geometry during the drying of the material. In the walls where there will be window and door openings, the material is selected depending on the size of the openings. In order to prevent the timber from deforming, when setting up the openings, a part of the bars is left to the size of the wall, and after shrinking, the excess material is cut out.

The floors of the 1st floor and the attic room are warmed with mineral wool. Flooring can be used any. Ceiling set up in the process of finishing works. Lining is very popular. The roof is often made gable. The simpler the geometry of the roof, the less often you will have to carry out repairs.

Before weatherization and finishing work, it is advisable to wait 3-6 months until the house is seated. If wet material was used, more time is needed. During the shrinkage of the house may appear cracks. To avoid heat loss, log houses from non-profiled timber caulk before finishing work. The job is to seal the gaps with jute fiber, it is performed from the outside and inside manually.

If profiled sawn timber was used in the work, it is enough to perform painting work. The coating layer should protect the house from water and UV light. Before painting the timber must be polished. Despite the fact that this will take some time, grinding will allow you to apply a paint coating economically and efficiently.

Recommendations for building a house from a bar

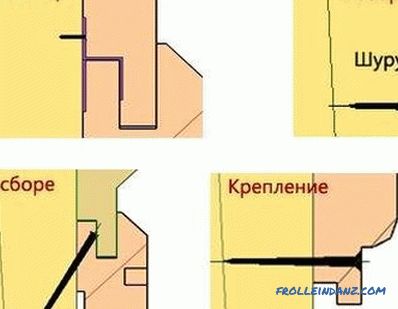

Building a wall of a bar.

- Before work, be sure to touch the beam, remove the chamfer.

- The building is assembled on dowels, without nails. Under them you need to make holes in the bar. For 6-meter timber, 4 pins are needed (2 - on the sides and 2 - in length at the same distance). If a window opening is placed in the wall, then pins are placed at the corners of the window box.

- When building a wall, install a draft window box. It is mounted to compensate for shrinkage.

- When collecting the corner joint, use the thorn-groove option. In one timber they make a thorn 50x50, in the mated timber a notch 50x45 is cut out. The difference of 5 mm makes it possible to make a caulker of corners. The next crown overlap. Angles are connected with dowels.

- Since the lumber is not perfectly flat, before laying it needs to be carefully checked: a flat bar is used for the lower and upper rims of the walls, the curve can be used for short lengths (window joints).

Now glued laminated timber is quite popular. The material is quite expensive, but it lacks the flaws inherent in the tree: it does not shrink, it has high fire resistance.

The technology of building a house from a bar includes many different works. Following the basic rules and sequence of work, you build a reliable and practical home.

Didn't find the answer in the article? More information on the topic:

-

How to properly fasten the eurolining?

Step-by-step instructions on how to fix the lining with your own hands. Materials and tools needed for work. Installation of this coating using klyaymerov.

-

Guide to covering the balcony with a tree

The process of covering wood balcony. The necessary tools and material for plating. Warming and creating a frame for plating. Features trim the walls of the balcony or loggia.