Since ancient times, the most popular building material has been wood. It was used in almost any area where it was necessary to build something. But in some cases, for special architectural ideas, ordinary logs can not be used. It is necessary to use other materials. After the appearance of laminated veneer lumber, it became possible to build buildings that were complex in their construction entirely of wood.

The appearance of the end slice of laminated timber with a description of the merits.

With such construction it is required that the technology of building a house from glued laminated timber should be done very carefully and attentively. When a house is built, the best and the highest quality materials are selected for it.

Natural materials that meet basic requirements are preferred. They must be durable, reliable and comply with the external design. The recently developed technology of building a house of laminated veneer lumber revived the lost interest in the construction of wooden houses. After all, recently houses that were built of brick have become very fashionable.

Project and its features

Every construction always begins with design. The construction of houses from glued timber is no exception. To carry out an independent development and design of the house of glued laminated timber will allow a special computer program. Of course, such work will require some knowledge. When developing documentation and drawings for a laminated timber house, you need to prepare:

A foundation for a laminated timber house.

- Foundation Plan. A foundation drawing is being developed, indicating its type, depth of trench, materials used, and so on.

- Floor beams plan. The type of support beams will depend on the type of the selected foundation. To do this, a special drawing is made, which will become the base for the future construction of the floor.

- Floor project of the building. Such documentation is considered the most time-consuming when developing a plan. The drawing must show the places where they will be: windows, doors, walls, internal partitions.

- For each part, all dimensions must be indicated. In addition, it is desirable that the executed drawing shows the location of the fireplace and the connections of all engineering communications.

- Breaking. When designing a drawing shows a section of the house wall. In accordance with these drawings, preparation of glued timber is carried out. This process is the most time consuming, it is necessary to pay special attention to it. I must say that this is the most difficult point of design. When the scrubbing technology is developed, the walls of the future building are drawn, an axial section is made, all the details of the wall are shown, its connection with other walls. In the final form of scrubbing of houses from glued laminated timber, a drawing of every detail of the wall is made. All major dimensions, hole diameters, cutouts and cups are shown.

- Numbering. Each project gives all elements an individual number with which it can be easily identified in the future.

Advantages of a laminated timber house

Positive qualities are ensured due to the technology of manufacturing laminated timber. It is first cleaned, remove all the knots, then sorted according to the texture and color shades. This technology allows you to get a great appearance:

Construction of the walls of the house of laminated veneer lumber.

- Constancy of overall dimensions. Glued wood is able to maintain its size. It does not change shape after long years of operation. Houses made of laminated veneer lumber do not shrink because the timber does not curl and does not begin to bend over time. The reason for such properties are the absence of internal stresses and ideally dried raw materials.

- Durability. Solid wood in this issue is much inferior to laminated wood. Its strength is half less than that of laminated veneer lumber. Therefore, such timber began to be used in the newest wooden house-building. Characteristics of houses from glued timber meet the requirements of construction technology.

Thermal performance of a glued timber house

It has long been known that any wooden house is warm. Excellent thermal performance makes it possible to save on the purchase of expensive heating equipment and fuel . To heat houses from laminated veneer lumber, it requires ten times less fuel when compared to a house built of bricks.

Building a wall in a house of laminated veneer lumber.

The time during which the construction of such houses takes place is much less than the time needed to build the same building if untreated wood is used. This was made possible due to the fact that glued laminated timber is manufactured at the factory with an exact dimensions of exposure and good drying.The design of the house is going very quickly, installation does not cause much difficulty. After laying the foundation, the assembly of the house takes about 5 weeks.

A lot of space is allocated to the weatherization of the house. In ordinary wooden houses there are seams, which are very difficult to seal. With houses from glued timber everything is much easier. During assembly, the bars are precisely sized to fit, so it is not necessary to install additional insulation to close the grooves. It should be noted that the design of such bars protects its middle from water. Such a house is never affected by rot.

Separate logs are very difficult to finish even with excellent fit. The walls still remain uneven, the finishing process is much more complicated. The walls of laminated veneer lumber are very smooth, the surface is completely smooth. Such a wall looks like a monolithic. To trim these walls outside is not necessary.

Nuances of construction from laminated veneer lumber

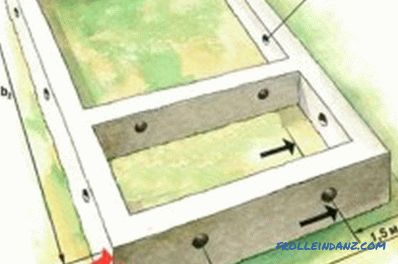

Any home begins with a foundation. For glued laminated timber use tape option. Such a foundation must have a well-ventilated space (directly under the house). Therefore, in this base special vents are provided, due to which the airing of the subfloor takes place. For each part of the strip foundation, there must be two dampers.

At the first stage, the dimensions of the strip footing are determined.

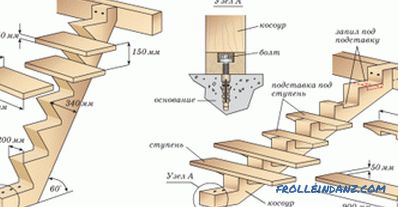

Mounting beam scheme.

A single-storey house from glued timber usually has a foundation that is poured to a depth of 800 mm. Its width reaches 500 mm. 15 cm of the excavated trench is covered with sand, which must be compacted.

After the work with the foundation has been completed, all construction is carried out according to the classical system:

- the reinforcement cage is made;

- formwork is mounted;

- the work is done pouring concrete.

Decking should rise about 300 mm above the ground level. Before pouring the concrete, it is necessary to prepare ventilation holes in advance. To this end, mortgages are inserted in the right places, which are subsequently knocked out. You can, of course, do without the device mortgages. It is possible to make holes using a perforator. However, such work is quite complicated and time consuming. Exactly one month waiting for the foundation to dry.

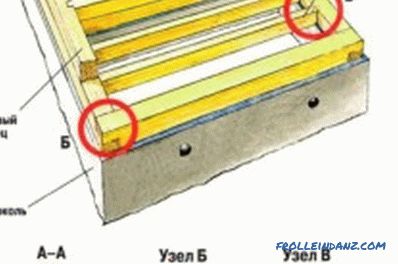

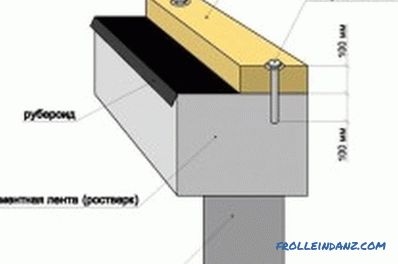

The second construction step implies the mounting of crowns. Before this operation, the foundation is covered with waterproofing material. First, the entire surface is coated with bitumen mastic, and then several layers of roofing material are laid.

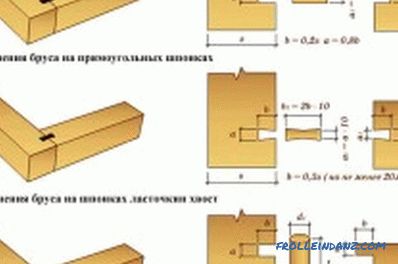

Layout of corner angle joint connections.

The installation of the crown is carried out on the insulation, which consists of beams that fit directly onto the foundation. First, the bottom strapping is done. Sex lags are put together with it, after which the first crown is assembled. This structural element is laid on the partitions: it is installed together with the bearing walls.

After completing the work with the crown, the construction of walls begins. In this case, the installation of the house of glued laminated timber is similar to the assembly of the designer. The beams are fastened with spikes, which are driven into pre-prepared holes. In this paper, much attention is paid to when corners are tied up.

The final moments of construction

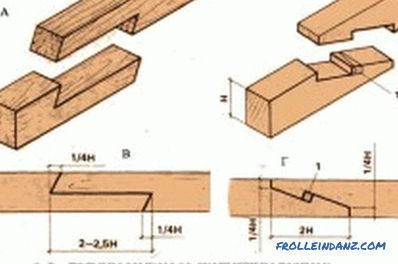

Connection of timber along the length with a direct patch lock and a slanting overlay lock.

One of the penultimate steps of building houses from glued laminated timber is to mount the roof. Its installation is similar in complexity to walling. As mentioned above, such houses are built on a special project in the factory. They are brought to the construction site in the form of finished parts that need only be assembled.

One of such details is the roof. In this regard, its installation requires only proper fastening of the necessary elements in specific places. Mostly similar houses have a roof made of colored shingles. I must say that only the roofing material in this case is not made of wood.

The final operation of erecting a laminated timber house requires only finishing the surface of the floor and walls. The most important work during this technological operation is floor fabrication. Usually it is a multi-layer construction, down which moisture-proof plywood is put. On top of it is mounted a special decorative coating. Both of these layers are separated by reinforced screed, sometimes a durable boarding is put.

Wall surfaces inside the house are most often made of wood, but decorating with other types of materials will also look good.

Didn't find the answer in the article? More information on the topic: