Regardless of the size of the kitchen, whether it is a spacious kitchen in a new building, a country house, or a small one in a small family, the most important piece of furniture is the kitchen table. For the production of tables today are used different building materials, for example, glass, metal, stone, plastic, wood. But of all these materials, wood is used more often. If you want to save, the kitchen table can be done independently. In this scenario, you can save up to 70% of the cost of the table. But first you should work hard and take into account a large number of factors that we will consider with you in this article.

We make important measurements and calculations

Measurements and calculations

Measurements and calculations

Before proceeding to work on the manufacture of the kitchen table, it is important to make some calculations. Typically, these tables are calculated on a specific number of people. Typically, this number ranges from three to nine. But it is best to take into account when calculating a couple of extra places, in case of the arrival of guests. If you are a hospitable host, then most likely you will need a large-sized table that can accommodate up to fifteen people.

Important calculations:

- The working segment for one person should be 60 cm. This figure is multiplied by the number of persons. The resulting figure will be the perimeter of the future table.

- How exactly the table will be set: in the middle of the kitchen, near the wall. In the first version, the table can accommodate a larger number of guests.

- Will the desk have drawers or other accessories?

From the tree

From the tree

You should decide on the size and location. The optimal width of the table is 80-110 cm. If a narrower table is planned, then you will have difficulties in serving. In the case of choosing the oval-shaped table, it is necessary to calculate the length of the circle. To do this, multiply the square of the radius by Pi (3.14).

Round or oval kitchen tables are necessarily located only in the center of the kitchen.

Tips and recommendations for the location of the table in the kitchen:

- Do not place the table near the stove.

- Do not set the table under the air conditioner.

It is equally important to determine the shape of the table. The surface geometry can dramatically change the look of the entire space. It depends on the form whether it will be convenient to eat or not. Most in demand is a rectangular shape with right angles. These countertops are great for square or rectangular kitchens. At the same time it can be placed near the wall or in the center of the room.

Oval-shaped

Oval-shaped

Oval-shaped tables are also very popular. There are several valid reasons:

- The oval table has an attractive appearance.

- There is no need to bypass the corners. This is especially convenient when there are small children in the house.

- The oval table is better suited for a solemn meal.

There is a large number of advantages in favor of an oval-shaped kitchen table. But in the presence of a large family, it is inferior to a rectangular shape. There are also round forms, but with this option it will be inconvenient to take certain dishes. As for the oval table top, the ideal diameter is 140 cm.

Round

Round

Rectangular with rounded corners

Rectangular with rounded corners

So, when choosing the shape of the table, push off, mainly, from your own taste. Moreover, remember that for a kitchen with an area of 8 m 2 and a smaller oval table will be impractical, as it will require a lot of free space.

Preparing drawings and tools

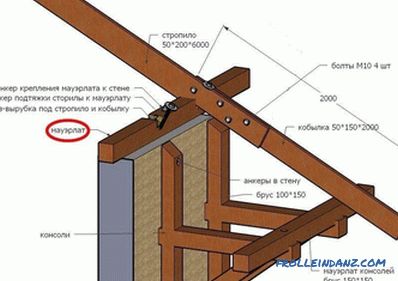

Mounting table layout with a round table top

Mounting table layout with a round table top

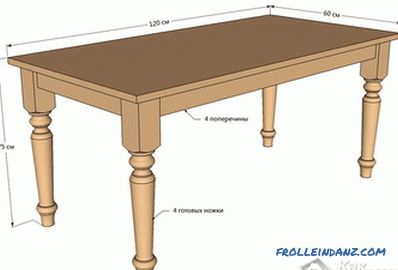

If you have decided on the size and shape of the kitchen table, then you can proceed to the next step - drawing up a drawing. It should display the required dimensions of the surface, legs and other elements. It should consider the method of attachment of various nodes. Consider, for example, a kitchen table, which will have the following dimensions: 120 * 60 * 75.

Although such a table will be small, in his example one can easily understand the principle of making such furniture. In your drawing you can resize the table according to your needs.

Diagram of a rectangular variant

Diagram of a rectangular variant

You will need:

- Tabletop 1.2 * 0.6 m - 1 piece.

- Crossing bars 40 * 2.5 cm - 2 pieces.

- Longitudinal jumpers 100 * 2.5 cm - 2 pieces.

- Table legs with a height of 70 cm - 4 pieces.

To build a worktop, it is necessary to prepare boards of the appropriate size. Before you begin, you need to think about the method of attachment of important components.

First of all, you need to collect all the necessary tools and materials:

- planer,

- hacksaw,

- electric jigsaw,

- drill,

- screwdriver,

- sandpaper,

- ruler or tape measure,

- square,

- pencil,

- circular saw,

- milling machine,

- file,

- clamps,

- painting brush,

- carpenter glue,

- polyurethane varnish: matte or glossy,

- solvent.

When everything is ready, you can get to work.

Assembly Guide: Requirements for the tabletop

What could be the tabletop

What could be the tabletop

As for the tabletop, it is important to determine whether it will be sliding or not. For example, the assembled table can be used for cooking, and in the sliding state as a means for eating.

The tabletop should not absorb odors and grease. Consider and practicality.

A good tabletop should not absorb moisture, withstand strong blows. The surface of the table should not be afraid of steam, condensate and heat. All these requirements correspond to the table top, made of natural and artificial stone or covered with ceramic tiles. But it should be noted that such a table will only look in the interior of modern style.

Ceramic Tile Coating

Ceramic Tile Coating

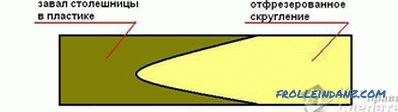

One of the most common types of worktops is chipboard laminated with plastic or plastic . For the price of chipboard available to many. Moreover, it is easiest to work with such material. Some may deny that the chipboard worktop is practical. This is partly true, but if properly processed, it will last more than one year. Here are some recommendations and tips for working with chipboard worktops:

- The film or plastic should be rounded at the ends of the particle board.

- Each rounded end is 90 ° treated with silicone.

- However, in this position, the butt is vulnerable to moisture ingress, therefore it is better to turn the butt through 180 °.

One should be objective and mention the disadvantages of such a tabletop. If the chipboard swells, then fix this problem will not work. As a result, you have to make a new table, or at least a tabletop. But, on the other hand, this surface is resistant to aggressive detergents and mechanical effects.

Chipboard worktop

Chipboard worktop

Of course, if we talk about the most ideal and environmentally friendly option, here on the right in the first place is a tree. But in the care of such a surface is more capricious. Do not allow moisture to penetrate the tree, allow scratches and other damage. Inside them microbes can settle and multiply, which negatively affect the mechanical strength of the wood. Therefore, from time to time, wood countertops must be varnished, cleaned, opened with a layer of wax.

Production of wooden tops

Production of wooden tops

Requirements for legs

Depending on the shape and the size of the table will vary the number of legs. For example, if you make a table made of laminated chipboard, then 4 legs, which are mounted on the corners of the tabletop, will suffice. If you make strong wooden legs, then this design will be durable and sturdy.

The legs can be made with your own hand. To do this, you can purchase a finished sketch. The complexity of this work will depend entirely on the shape of the legs. If you think that you can’t do it, then get ready-made metal legs or choose wooden carved. Everything will depend on your financial capabilities.

The table can be on one leg. As mentioned above, this will depend directly on the weight, shape and configuration of the table top and the table as a whole.

A table with one massive leg looks spectacular and beautiful from the side. For its installation, high-quality cross-bracing is performed.

On one leg

On one leg

Two massive legs are located at a certain distance from each other. In most cases, a table with two legs, is rectangular or oval. The advantage of such structures is that the legs will not interfere with any of the people sitting. As for the design of such legs, they expand at the bottom to increase the footprint. Between themselves, they are connected by a jumper board.

On two legs

On two legs

But even ordinary tables on four legs are simple in design and do not need accurate and complex calculations. This table is stable and durable. Here the most important thing is to choose the right size of the legs and mount them at the correct distance. In this case, the tables on four legs can be very different in shape: oval, round, square, rectangular.

On four straight legs

On four straight legs

So, regardless of the number of selected legs in your design, the most important thing is always their aesthetics remains.The aesthetic appeal of table legs is even more important than the beauty of the tabletop. After all, the table top is always covered with a tablecloth or oilcloth, and the legs are always visible.

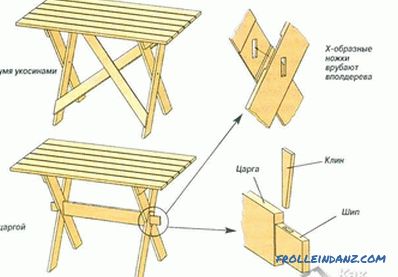

We construct a folding table

Sliding tabletop mechanism

Sliding tabletop mechanism

One of the simplest forms of kitchen The table is rectangular. This design consists of four legs and six sides of the box. The table top and sides can be made of chipboard 18 mm, and the legs of the bar 40 * 40 mm. First you need to make the backs of plywood, 2 cm thick (table legs will be attached to them), as well as two horizontal planks. The removable part of the table will be placed on them. In our case, for the manufacture you will need to purchase the following material:

- Self-tapping screws 4 * 16.

- Self-tapping screws 4 * 50.

- Furniture corners 30 * 30.

- Laminated edges of the chipboard color.

- Wooden dowels 8 * 40.

To extend the table, you can use standard guides. They provide smooth movement of the table top. So, pre-made all the necessary details of the following sizes:

- Leg 710 mm.

- Two fixed parts of 450 * 700 mm.

- Removable part of 400 * 700 mm.

- For the box of the non-removable part there are four sidewalls 420 * 120 mm.

- For the box for fixed parts, two end 600 * 120 mm.

- Of plywood, two side bones of 830 * 120 mm.

- Out of plywood, two end pillars are 498 * 120 mm.

- For placement of a removable table-top two laths of 498 * 120 mm.

With such blanks you will have a sliding table of the size:

- In the extended form, 1300 * 700 mm.

- When assembled, 900 * 700 mm.

Cutting all the workpieces is best on special equipment. It is important to precisely withstand all sizes. All blanks of plywood and wood should be carefully cleaned and varnished in two layers.

So, step-by-step instruction:

- First of all, the lateral and longitudinal side rails on the outer side of the legs are fixed flush with the ends. After, with the help of screws 4 * 50 mm from the outside and from the inside 4 * 16 mm corners are attached. The corners are attached to the longitudinal arches through the horizontal bars.

- Next, a wide guide is fixed on the inside of the lateral side-bar.

- Under the dowels, you will need to drill two holes in the inside ends of the table top. They are attached for collapsible connection, that is, one half will be free, and the second - mounted on glue. From the dowel to the edge of the tabletop the distance should be equal, but not exceed 10 cm.

- Two dowels are mounted on the removable tabletop. For this, two holes are drilled from the back side.

- At the next stage, it is time to assemble the U-shaped parts of the box from chipboard. In this case, the end elements 600 * 120 should be located between the sidewalls 420 * 120 mm.

- Now fasten the narrow guides. This is necessary in order to chipboard box moved an average of 2 mm above the plywood collet.

- After, the guides are latched and checked for movement along the bar.

- With the help of corners and 4 * 16 mm self-tapping screws, attach the non-removable part of the tabletop. Both parts must match perfectly. Therefore, immediately prior to their fastening, slide both parts and check their coincidence. After that, gently push apart the side bars and secure the countertops.

- On the shelf inside the table, place the removable part of the tabletop.

Folding table - the original solution for a small kitchen!

Folding design

Folding design

If your kitchen has miniature sizes, then choosing the appropriate form of the kitchen table can be difficult. However, there is always a way out. For example, you can build a homemade folding table. In the folded state, it will serve as a decorative frame, and in the unfolded - a full table for lunch. Although in each individual case the size of such a table will be different, we will take our dimensions as a basis. This will allow you to visualize what your drawing will look like.

The following are required for work:

- MDF board 180 mm thick - 5 pieces,

- 150 * 90 cm,

- 130 * 10 cm - 2 pieces,

- 90 * 20 cm,

- 70 * 20 cm,

- joiner's vice,

- joiner's glue,

- putty acrylic,

- electric drill,

- drill for wood 3 mm and for metal 8-10 mm,

- sandpaper,

- acrylic paint for wood,

- roller,

- masking adhesive tape,

- screws 3.5 * 30 and 3.5 * 16 mm,

- hinges,

- screwdriver,

- two furniture latches.

The whole process of work will not take you much time if you precisely follow the below step-by-step instructions.

- Based on the set of material, the table will be made of MDF. Pre-make the drawings.

- First, the frame is constructed. To do this, four smaller elements are attached to the bottom board with the help of a joiner's vice.Every 250 mm in the frame, holes are drilled with a Ø3 mm drill bit, up to 3 cm deep.

- After, a hole to a depth of 3 mm is drilled with a Ø8-10 mm drill bit. Thus it will be possible to deepen the caps of the twisted screws.

- Next, carpenter glue is applied to the bottom surface of the four frame elements, and after that, each element is applied to its place. Each of them must be well pressed with a carpentry vice.

- Attaching the frame to the glue is not enough; therefore, you should additionally fasten it to the screws.

- At the same time mask the screw caps so that they do not spoil the overall look. To do this, you need an acrylic putty.

- When the putty has dried, you can sand the surface of the decorative frame with emery paper.

- The ends of the table top should be glued with masking tape.

- Paint the surface of the frame with acrylic paint using a roller, and paint the corners and edges with a brush.

- On the short edge of the tabletop, then screw the hinges. From the edge should be at least 150 mm. Mark holes on the wall and drill under the dowel. Thus, the hinges will be bolted to the wall.

- When the table is in an upright position, it will be held on top with bolts. They should be fixed so that they do not catch the eye, for example, at the edges of the wall shelves.

Table from postforming-tabletops in 5 stages

Table-to-postforming

Table-to-postforming

Such a table can be performed in the shortest possible time. To do this, you will need to first collect all the necessary material and tools. You will need:

- pencil,

- postforming worktop,

- jigsaw,

- jig saw,

- sander ,

- cant,

- cutter,

- silicone sealant,

- rubber mallet,

- sharp knife,

- clamps,

- metal legs with holder,

- allen key.

From the post-forming tabletops

From the post-forming tabletops

All work can be done in 5 consecutive steps.

Stage 1

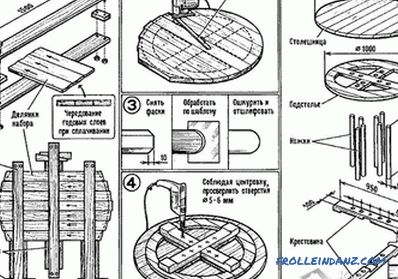

Put the markup on the front side of the tabletop with pencil. The markup will match your drawing. Each rounding is performed with a radius of at least 60 mm. This will prevent discoloration of the edge at sharp bend points.

Stage 2

Now you need to shape the countertop. To do this, use the jigsaw. When cutting, it is recommended to leave a small margin of 2-3 mm. Pay attention to the direction of the jigsaw. It should have a reverse tooth direction. This will avoid chipping on the plastic coating. Although in part they can be hidden by edging. In order to accurately bring the dimensions and outlines of the table top, it is necessary to work the ends with a belt-type grinding machine.

Stage 3

Milling the

Milling the

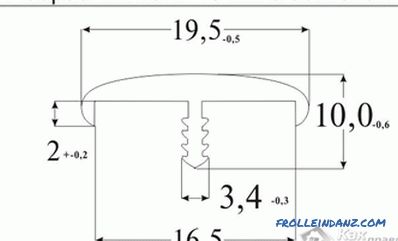

slot In the third step, it is time to mill the slot . Milling is always done strictly in the center of the end. And this is even regardless of whether the edge exactly matches the thickness of the tabletop or will be large. If you do not have a mill with the exact dimensions of the groove of the edging, then you can walk several times with a mill having a smaller tooth height.

Stage 4

T-shaped edge

T-shaped edge

When the groove is ready, you can proceed to the Kant stuffing. To do this, the pre-end is covered with silicone sealant. This will prevent the ingress of water. Sealant is applied to the upper edge of the edge. The edge itself is stuffed with a rubber mallet. The joint should be formed in the most inconspicuous place. When the packing is complete, it is important to make an exact edging. It can not do without a sharp knife. After that, you will need to remove excess sealant, which was formed when driving the edge, along the entire perimeter of the tabletop.

When fixing the table tops using clamps, it is important to use special gaskets. They are installed on the protruding edges of the edge and prevent their damage.

Stage 5

Installing the legs

Installing the legs

At the final stage are fixed legs. To do this, you should fix the cast holders on the bottom side of the table top. So that they are at the same distance, make the markup with a pencil. From the edge of the leg should be at a distance of 10 cm. This holder is fixed with 2.5 cm self-tapping screws with countersunk head. Now it remains to make the final touch: fix the legs in the holder with an allen key. The dining table for the kitchen is ready!

As you can see, the table from the postforming-tabletop is very simple and, most importantly, is available for home-made production at home. To do this, you must have basic carpentry tools. But here it is necessary to remember the dangers. With careless handling, there is a risk of breaking the holder, which is made of brittle material.But if you carefully operate such a table, it will last for many years.

The choice is yours only

We have considered several options with you how to make a kitchen table. There are other technologies for its manufacture. In most cases, everything will depend only on your financial capabilities and ingenuity.

Video

This video shows an example of making a rectangular kitchen table with rounded corners. Balusters are skillfully used as legs: