Anyone who was interested in building a private house or even more so erected such buildings, knows what a power plate is and how important it is to fix it properly for the entire structure. For those who are not familiar with the construction business so far, we will clarify that the mauerlat is a special wooden structure, the purpose of which is to take the main load from the roof and distribute it evenly along the walls of the house. It is to him that the feet of the rafters are attached, and they ensure the structural stability of the entire roof.

Mauerlat attachment to aerated concrete.

Reliable and competent mounting of the power plate to the walls is a responsible operation, since not only the strength of the entire roof, but also its durability depends on its accuracy. In fact, the mauerlat may even be in the form of an I-beam or a steel bar, if the rafters on the roof are also a metal system, but such cases, especially in private construction, are extremely rare.

The reliability of attachment to aerated concrete directly depends on the accuracy of all preliminary calculations and installation techniques. The minimum section of a wooden bar or log is 10x10 cm, but more is better. If it is planned to use a log as a power plate, then it should be cut off on one side so accurately that it fits tightly to the upper face of the aerated concrete wall.

Material selection and calculation of parameters

Installation of a power plate carries two main functions:

- Uniform distribution of the load from the roof on all the load-bearing walls of the house.

- Fastening the roof structure to the construction box.

A wooden bar with a size from 10x10 to 15x15 cm is used as the base.

A wooden bar with a size is taken as the base , as mentioned above, from 10x10 to 15x15 cm. It is best to take a timber from hardwood, which must first undergo an antiseptic treatment. All the bars should evenly cover the entire top of the walls, and a straight lock is used to securely fasten them together. In this case, it is better to further strengthen the lock by hammering in to fasten the nails.

As a result, you will have a single rigid system, when the bars securely fasten with two adjacent ones and form a reliable support for future rafters. Bars are always a little narrower than masonry from gas blocks, so they need to be moved to the inner edge so that there is free space between the bar and the outer edge of the wall at least 5 cm wide. In some cases, a row of bricks are placed on the outer edge, into which the sides of the mauerlat will rest.

Remember that before proceeding to fastening the mauerlat to aerated concrete, it will be necessary to lay high-quality waterproofing between the tree and the wall.

Variants of fastening of the mowerlat

In total there are several ways how to fix the mauerlat to aerated concrete. Due to the fact that this fastener must be as durable as possible and not allow even the slightest changes in the structure, in the modern construction technology several highly reliable types of fixing these elements between themselves are used. This mount with:

- robust steel wire;

- anchors embedded in the reinforced belt;

- metal studs protruding from the reinforced concrete belt.

Consider these types of fastening to aerated concrete in more detail.

Steel wire fastening

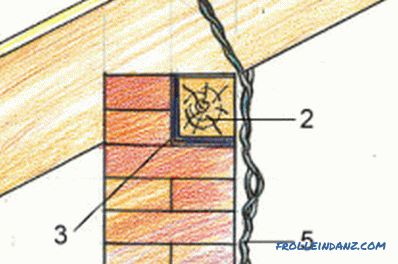

Mauerlat fastening with wire: 1 - Coupler, 2 - Mauerlat, 3 - Hydraulic insulator, 4 - Rafter, 5 - Wire , 6 - fasteners.

Even when laying the walls, two or three rows to its top, steel wire is pushed in between the bricks so that its middle is fixed with bricks.

Both ends must be of such length that they are enough to secure the timber to the wall. To do this, the wire must go through the hole in the mauerlate and securely tightened.

The number of such bundles is not regulated, but their number is better to equate to the number of feet of rafters.

Fastening with anchor bolts

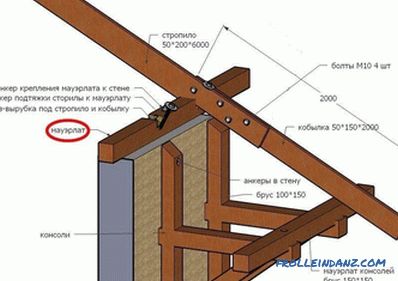

For better fastening of the Mauerlat, experienced builders advise to build a reinforced belt. Apart from the fact that with such a concrete belt, fastening to a timber will be convenient and reliable, the armor belt also increases the strength of the entire box as a whole, making it more rigid. In addition, the reinforced belt makes it possible to perfectly align the upper border of the walls horizontally, which is extremely important for ensuring both durability and reliability.

Mounting plate with anchor bolts.

If the walls of the house are made of aerated concrete, the mounting of the power plate is impossible without armor, as the aerated concrete itself is too soft material to ensure reliable fixation of anchor bolts, studs or other fasteners.

It is best to build a reinforced belt using special U-shaped blocks that are laid on the upper face of the walls so that a single and continuous line of the gutter is formed. At the corners, blocks with a sawed sidewall are used so that the line of the gutter is not interrupted. It is in this trough that the reinforcement is installed from 12 and 6 mm (transverse) rods. After installing the reinforcement cage, the gutter is poured with concrete mix, while doing this continuously and in one go.

But even before pouring concrete into the gutter of the reinforced belt, anchors with thread are installed. They are fastened with knitting wire. Their fastenings should be as flat as possible; for this purpose, a stretched cord or fishing line is used. Anchors should be as close as possible to the upper surface of the concrete and to the bar, respectively, while standing as perpendicular to the line as possible.

The number of fasteners is not regulated, but their number should not be less than the number of rafters, while you need to place them so that they are not covered by them, so try to mark the fastening points as accurately as possible.

Mauerlat fastening with waterproofing.

After the concrete solution hardens, the anchors are securely fixed in its thickness. This mount is the most reliable of all imaginable options.

After the final drying on the concrete belt and anchors, the bars are laid in such a way that the anchors penetrate into the holes drilled in the tree beforehand. After this, the fastening takes place by tightening the nuts and washers.

In order to accurately calculate the space for the future of the holes for anchor bolts, you need to lay a bar on top of the bolts, and then hit the rammer or its equivalent several times on top. There will be dents in the wood from contact with the bolts, and you need to drill holes in this place.

Sometimes, in order to save money, they do not make a solid concrete belt along the entire length of the wall, but separate concrete pillows. That is, they make an analogue of pits in the brickwork, where fittings are laid and concrete is poured using the same technology as the belt. There it is also necessary to attach anchor sockets to the reinforcement bars.

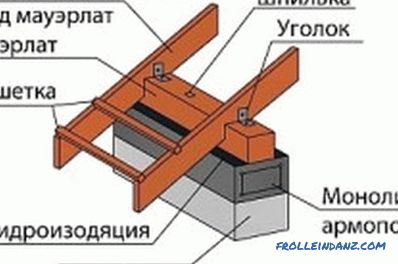

Fastening with metal pins

Fastening of the power plate with metal pins.

If you have a small house and the pressure on it from the roof side is not supposed to be too large, then you can use the lighter mounting option to fasten the walls with the Mauerlat bar - wall studs embedded in the wall. These studs are steel fasteners in the form of bolts with a cross branch or base in the form of a square with sides of 5 cm.

At the construction stage of brickwork, these studs are bricked into the wall, they are installed one or two rows before the end construction. The free length of the studs should be sufficient to pass through the bar or fix the lock nuts.

Further technology resembles fixing with anchor bolts. Also marked places for drilling holes, set the bars and tighten the screws.

The importance of waterproofing during installation

By selecting one of the proposed mounting options, carry out an exact count of the fasteners you need and their future location. In addition, it is necessary to hold one important event.

This is a good waterproofing provision.

Several layers of suitable waterproofing should be laid between the wall and the wood of the beam.

It can be either plain roofing material or polyethylene, or expensive modern materials. The need for such isolation is extremely important, because without it, moisture will accumulate at the point of contact, which is capable of destroying the entire structure of wood as soon as possible. Only after the installation of the chosen insulation can the installation of the power plate continue.

Didn't find the answer in the article? More information on the topic:

-

Technology for laying lining inside the house

Laying lining: preparatory work, the manufacture of frame construction, fixing the insulator and vapor barrier. Installation of lining in different ways to the surface of the frame, painting the lining.