For any bath: brick, panel, frame, from a bar or from foam blocks, the main attribute is the furnace. Her heat provides high temperature in the steam room, heats water for procedures. Stoves for such a room do not have a limitation in the material, you can weld or buy an iron model, or follow the Russian tradition and fold the stove. In this article we will look at how to build a sauna stove for a bath with your own hands.

The merits of a brick stove

Brick stove-heater

Brick stove-heater

The stove is made of brick, has a large closed heater, the design of their other material can not compete with it on the quality of the resulting steam. The advantages of this design are:

- fire safety;

- long-term heat preservation;

- the ability to heat a large area;

- ease of operation and no need to pop up fuel in the process of washing;

- uniform heating of the room;

- lack of contact between stones and combustion products.

The disadvantages of a stone stove include its impressive weight, which requires laying a separate foundation, and the need to preheat the bath.

Metal heaters: pros and cons

Made of metal

Made of metal

If you wish, you can to weld the steel furnace for a bath. Above her firebox is set capacity for stones. This option is cheaper and is made faster and easier than brick construction. Cast iron for metal metal heaters cannot be used, cracks occur when water gets on it. Among the advantages of a steel heater:

- compact size;

- low weight;

- fast warming up.

When choosing how to make a sauna stove, the disadvantages of a stove are also taken into account; rapid cooling after the cessation of combustion, uneven heating of the bath, fire hazard.

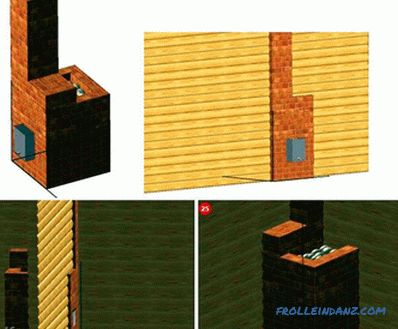

The brick stove is installed so that it heats all the rooms. Its front part with a furnace door and an ashpit is sent to the waiting room. The place for the construction is selected when designing the bath, because you need to take into account the necessary distance from the wall to the stove and arrange a solid foundation.

Location of the heater

Depending on the area of the double room, an appropriately sized stove is being designed. If, as a result, the heater takes up to 2 m 2 , then it can be installed in a specially made niche in the wall. Due to this, it is possible to prevent heat loss, since its heating will be carried out directly from the steam room. Although in most cases, the stove is designed in such a way that its firebox is carried out from the next room.

The stove-heater for a bath should be installed so that the heat from it spreads to the dressing room, washing room and steam room. Thanks to this, it will be possible to make a common chimney with three separate chimney channels for a gas boiler, a fireplace and a stove-heater.

Water Tank

Immediately before building the stove, it is important to determine the volume of the tank capacity in which water will be heated. The volume of the tank will depend on the intensity of visiting the steam room. So, the calculation is made on the basis of one liter of hot water per person. It is best to use an open container. Although there will be evaporation, but there are a number of positive aspects:

- Convenience when filling the tank.

- Possibility to carry out maintenance or repair of the interior as needed, for example, to remove scale, clean and dry.

- During the winter period, completely remove the water, protecting the tank from freezing water in it.

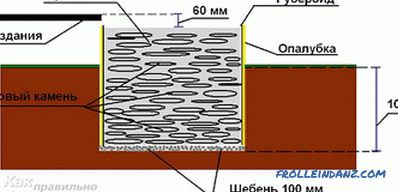

Foundation for brick stove-heater

If you want the furnace you have made to serve for more than one year, you should take care of making a reliable foundation for her In this case, be sure to consider the following nuances:

- The foundation of the bath and the heater should be different, especially if the total mass of the furnace exceeds 700 kg. There must be a distance of at least 500 mm between them.

- The foundation for the heater should have a depth below the soil freezing level on average 700 mm. In different regions of Russia, the level of soil freezing is different.

- In size, the foundation must be larger than the stove itself on each side on a half-brick.

So, consider the step-by-step process of making the foundation for a stove-heater:

- To begin, dig a foundation pit below the freezing ground depth, 700 mm on average. The size of the pit around the perimeter should be 100-150 mm wider. This will allow the formwork to be installed without difficulty, and the resulting gap be covered with sand or gravel.

- At the bottom of the pit we make a sand pillow. At the exit it should have a thickness of 150 mm. Having poured a layer of sand we pour it with water for compaction. As the water is absorbed, the sand will settle, respectively, you will need to pour it to the desired thickness.

- When the water is completely absorbed, a layer of stones or broken bricks is poured over the sand. It must be tamped. The gaps between the stones should be filled with sand, pouring water. It is very important that the sand fill the space between the battle and the stones as tightly as possible. The thickness of this layer, in our example, will be equal to 250 mm.

- If the sand has stopped settling, then the next layer of rubble can be filled. It also needs to be tamped well.

- Now you need to make a formwork of boards with a thickness of 40 mm. The internal size of the formwork must match the size of the foundation. The top of the formwork must be level. It should be securely fastened in the pit and put a reinforcement cage inside it. Between the formwork walls and the frame should be 50 mm.

- In the next step, perform concreting. At the same time it is necessary to produce tamping with a piece of steel reinforcement or a wooden bar. The upper level of liquid concrete must be brought to the edges of the formwork. The surface of the screed should be flat. As a result, the formwork should have the same level as the draft floor of the bath. Flooded concrete must be left for a few days to set.

- When concrete has gained sufficient strength, the formwork must be removed. The surface of the concrete is covered with two layers of molten tar. After that, fill the space between the walls of the soil and concrete - sand or gravel. After this, cover the concreted area with plastic wrap and wait for 7 days. Then you can proceed to the brickwork.

Butted concrete foundation

Another alternative for making a foundation for a heater is also known. The sequence of its manufacture is as follows:

- A foundation pit is also dug with a reference point of the level of soil freezing. Its size should be wider around the perimeter and in depth by 100-150 mm.

- If the ground water does not appear in the pit, and the walls do not crumble, then you can begin to lay a foundation for concrete.

- At the bottom 150 mm thick, you will fall asleep rubble. It should be tamped well. At the same time, the ground should be horizontal.

- After this, formwork is made. In appearance, it is a box without a bottom. Its size should be consistent with the foundation design plan.

- The inner walls of the formwork are covered with hot bitumen or roofing felt for waterproofing.

- Next, immerse the formwork in the pit.

- At the bottom you lay out the first layer of large stones Ø up to 15 cm.

- The resulting voids between the stones must be filled with rubble.

- A layer of cement-sand mortar is poured from above. The consistency of the solution should resemble a thick cream. It is prepared as follows: Portland cement М400 or 500 is one part and 3 parts of sand. Water is added until the mortar consistency resembles thick cream.

The foundation for the stove with waterproofing

The foundation for the stove with waterproofing

After these actions, you can follow one of the following Below the paths:

- Spread the first row of stone with mortar. Leave it for a day. After spilling the second row of stone also with a gap in the day. And so on until you get to the desired level.

- If the volume of the foundation is small, then concrete can be poured in one go.

The level of the foundation should not reach the level of the finishing dale by 60-70 mm. The top layer of the screed must be checked by level. After that, the surface is smoothed and covered with plastic wrap. In a week, the foundation will be ready for masonry construction.

The rate of drying of the concrete will depend on weather conditions. Therefore, in some cases have to wait more than one week.

Base plate on piles

Foundation screed

Foundation screed

Consider another option of production of the base under the furnace Kamenka. A reinforced concrete plate 150 mm thick is laid in its base. Its lower layer must be reinforced. The greater the area of the installed plate, the more reliable the entire structure will be. But how to be if the prevailing soil is moist clay and loamy? Such a plate will not be able to balance the force of frost heaving when the soil freezes. Among other things, even in sandy and dry soils seasonal movement of the foundation can be observed. To get out of this situation and increase the stability of the foundation under the slab, several piles are laid, on which the slab will later rely.

You can make such piles as follows:

- Using a garden drill Ø20 cm, you drill a cylindrical pit 1000 mm deep.

- The bottom of the pit is covered with a layer of crushed stone 150 mm thick and tamped down.

- After this, take the roofing felt and turn the tube out of it, which will serve as a formwork in the pit. This tube is immersed in a hole.

- Next, pour the concrete into the pit to the level of the slab installation.

- After an average of 10 days, it will be possible to install a reinforced concrete plate on piles.

The foundation must be waterproofed on the upper edge. This will prevent moisture penetration of groundwater to the brick construction of the furnace. For this purpose, lay 2 layers of roofing material with an overlap on the installed plate, which is coated with hot bitumen. In this case, the roofing material should go beyond the foundation by 50 mm. The second layer of roofing material is laid perpendicular to the first.

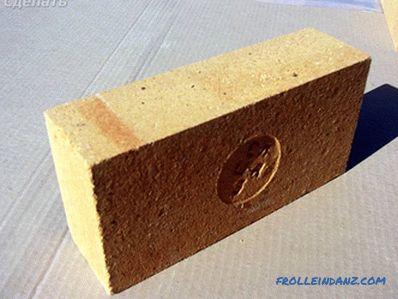

Brick for masonry

For the masonry of the stove, it is important to acquire a well-baked and high-quality brick. It should not have chips, cracks. His face must be smooth. The quality of the bricks can be checked very simply. If during the fall it falls apart into several large pieces, then the brick is suitable. If it falls into many small pieces during a fall, then such a batch of bricks is not suitable for the stove.

For masonry, the best option is a stove-top (ceramic refractory brick). Ideally, the size of such a brick should be 125 * 250 * 65 mm. However, it is extremely difficult to find a batch of bricks in which the dimensions do not differ from each other. Therefore, the choice of bricks go carefully.

Before the beginning of laying, many bricklayers lay brick on the dry one, leaving the necessary gaps in the seams. So you can avoid a lot of mistakes.

There is another type of brick that has only 3 sides burned. One side does not burn. This side is laid out. But such a brick is rare, therefore, red ceramic bricks are most often used.

Red and refractory bricks

Red and refractory bricks

As for the fuel zone, the chamotte brick Sh5 is used here. It is light pink, white or yellowish. This brick withstands high temperatures. In terms of its dimensions, it is different, since in most stoves the firebox made of fireclay is not associated with the basic laying of the furnace body. Moreover, there is no need to adjust their rows to the same level. But if this is required by the situation, then the brick can be cut to the desired size.

It is not recommended to use fireclay bricks for laying the furnace itself. This is due to the fact that chamotte does not accumulate heat, it cools quickly. Its main advantage is that it can withstand high temperatures.

Mortar for

For the masonry of chamotte bricks, a solution prepared from white chamotte refractory clay is used. You can also purchase ready-made composition for masonry chamotte. Putting the whole oven on this solution is impossible. Why? At a temperature of 700-800 ° C, this solution is sintered in a monolith. In the outer masonry there are no such temperatures. Therefore, after a short time, it will crack and spill out, which will lead to the destruction of the masonry.

For outdoor masonry, a solution of quartz sand and clay is used in a ratio of 1 (clay): 5 (sand). The sand should be of river origin or career. River sand is somewhat worse, since its sand grains are round, round, and the solution itself will have worse characteristics. Therefore, preference is given to career sand. The sand is sifted through a grid with cells of 2-2.5 mm. This will prevent large particles from entering the solution.

As for clay, it can also be mined from a quarry from a depth of at least two meters. You should check the quality of the clay. To do this, soak 200 g of clay per day in water. After that, roll the clay into a "bun" and put it to dry under a canopy in the open air. After 2 days from a height of 170 cm, drop it onto a stone slab. If the "bun" crumbled into several large parts, then the clay is suitable.

The selected clay must be soaked in water to a paste and grind through a sieve. First through large cells, and again through small ones.

Required tool

For laying the stove, you will need to have such a set of tools:

- a small trowel;

- hammer pickaxe;

- square 60 * 40 cm;

- plumb;

- steel level 60-90 cm;

- Bulgarian with stone cutting disc;

- safety glasses.

Laying

The laying process is very laborious and complex. Here there are a large number of subtleties and nuances, the understanding of some comes only with experience. Therefore, in order to make it easier for you to do this work, there are several videos in this section, which step by step tell and show how to lay out row by row.

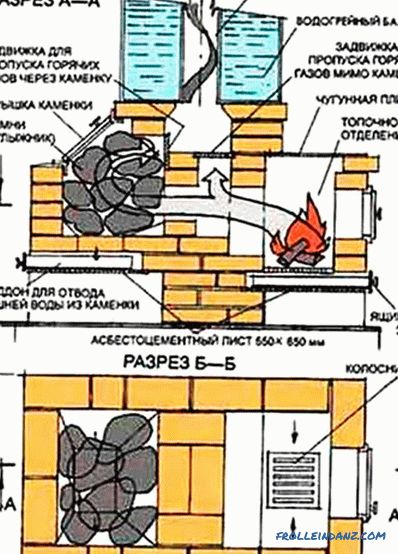

For example, consider the manufacture of an open small stove-heater. The size of such a furnace is 102 * 62 cm. It is able to heat the steam room with a tank, while having the tank itself separately. It uses an interesting water heating system - an open siphon. So, at a small angle a pipe is welded into the tank, which is sealed at the end. It should be under open fire in the furnace. As soon as the water in the pipe boils it rises into the tank, and in its place comes cold.

The diagram below shows an example of a stove with an open heater:

A diagram of an open heater

A diagram of an open heater

As well as the scheme of the order of the firebox of an open stove:

The order of the firebox

The order of the firebox

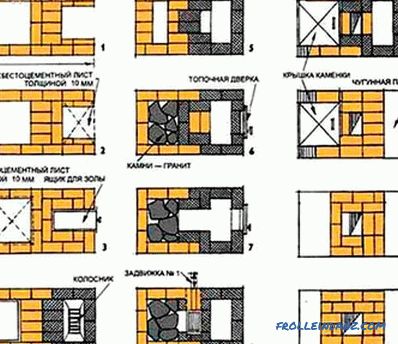

The ordering of the masonry is shown below brick stove:

Brick laying order

Brick laying order

If you want to make a closed stove, then consider that it is much more difficult to implement. There are many nuances that must be considered when laying it. It is rather difficult to describe the whole technological process, so we suggest that you watch the introductory video. The peculiarity of such a furnace is that the reservoir for stones is laid out of fireclay bricks:

Video about making a closed stove-heater:

It should be noted that at the end of the laying the drying should make up 10 days. At the same time, drafts are unacceptable. Only after this time can the first firebox be produced.

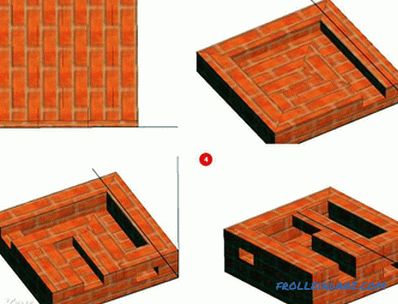

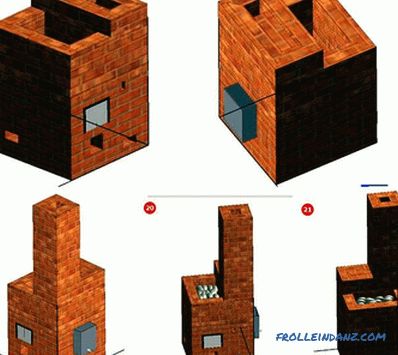

Photoinstruction of the order of the stove-heater

Stage 1-4

Stage 1-4

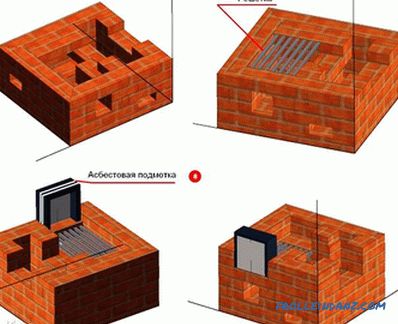

Stage 5-8

Stage 5-8

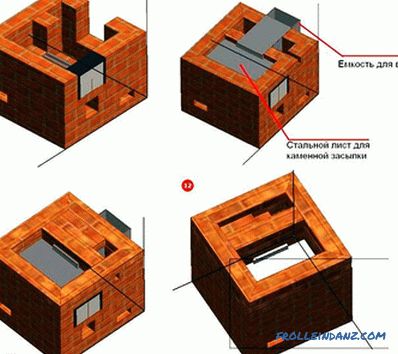

Stage 9-12

Stage 9-12

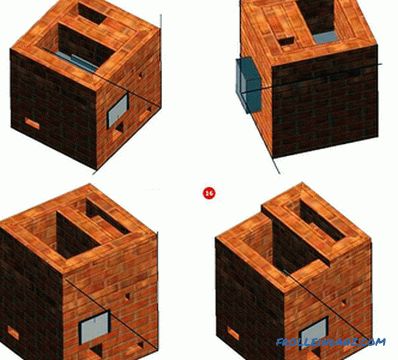

Stage 13-16

Stage 13-16

Stage 17-21

Stage 17-21

Stage 22-25

Stage 22-25

The construction of the firebox and ashpit

It is very important to correctly calculate the dimensions of the firebox. It should take into account various factors ranging from the presence of a collector to water heating and ending with a type of fuel for heating the bath. On average, the depth of the firebox is 800 mm. 250 mm is allocated for the hot water system, and 550 mm is the usual length of wood. The height of the firebox can reach 350 mm, and its width is 400 mm. With such dimensions, from 8 to 10 logs of firewood can be placed in the furnace.

The ashtray with a tray and a blower is intended for collecting products of fuel combustion. They also provide air flow into the firebox, which enters through the grate inside. To regulate the intensity of combustion of firewood is used valve or tray for ash. If it is necessary to warm up the steam room quickly, then the pallet moves away almost completely for a while. When the firewood broke out, you can push the pallet.

In this video you can familiarize yourself with the installation process of the blower door with a locking overlap:

Chimney

Furnace Kamenka differs from its analogues in that natural stones are used for heat accumulation. The first pipe segment passes exactly through such a compartment with stones. Also, the chimney can pass inside the tank with water to heat it. In all other respects, there are no particular differences in the construction of the chimney. It can be assembled from sandwich pipes or from ceramic blocks. Manufactured chimney necessarily insulated.

As for the bottom of the chimney, it is made of steel, right up to the ceiling. You must install the gate when passing through the ceiling pipe.

The gate is designed to improve the intensity of combustion, as well as to regulate the thrust.

If a sandwich pipe is used, then it has two walls, between which there is heat insulating material. They can be installed in the area from the ceiling to the fungus on the roof. Basalt mats are used for warming brick chimney. They are wrapped with a pipe. Wire is used to fix the mats. An umbrella or a fungus is always installed on the chimney. This will protect the chimney from falling into it.

When constructing the chimney, you should decide what type it will be: external or internal.

With other subtleties of the chimney arrangement, you can get acquainted with the video:

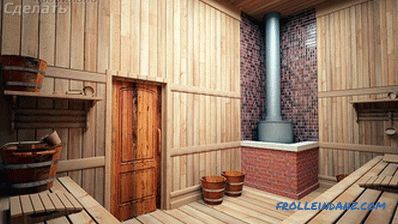

Finishing

Most often, the stove is left without finishing. Red brick is laid out under the jointing, and all the bumps and irregularities are polished. It is also practiced to enhance the color of the brick with a solution of sulfuric or hydrochloric acid. However, the stove can be plastered or tiled.

If you decide to plaster, then the layer must be made up to approximately 15 mm. For this work, you can use the following compositions with the proportions:

- clay (1) - asbestos (0.2) - sand (2);

- lime (2) - sand (0 , 2) - asbestos and plaster (2);

- sand (3) - clay (1) - cement (1) - asbestos (0,2).

Immediately before plastering, the furnace is heated. After this, the first continuous layer is moistened and applied. When the first layer is grabbed, the next layer is applied. As a result, the wall surface should be rubbed so that the wall is smooth and looks neat. At the end you can make whitewash.

Commissioning

Before you are going to melt the stove, give it a good dry. To do this, open the doors, the blower and the views open for 7 days, so the oven dries faster. If the stove does not smoke when it is fired, then the traction is good.

Do not rush with the kindling of the stove.Otherwise, if there is insufficient drying, cracks may form in the masonry.

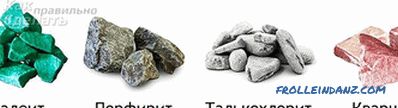

Selection of stones

River stone

River stone

Based on the name of the furnace - kamenka it uses special stones that are sanitary and geological examination. As for the concrete choice of a stone, several options can be distinguished:

- Talkochlorite.

- Jade.

- Gabbro diabase.

- Crimson quartzite.

- Porphyrite.

For baths, sea stones are considered to be the best option. However, this opinion is unreasonable. As practice shows, a river stone can withstand high temperatures much better. Sea stone is very quickly destroyed, as it does not have sufficient strength.

Types of stones

Types of stones

But besides the type of stone, it is necessary to choose the right size and shape. For example, it can be medium stones with a smooth structure. Remember that the stones should be enough, as this affects the quality of heating and steam release.

So, when deciding which stone is best to use for the stove, remember not only practicality, but also the beauty of the room. Beautifully shaped stones will be a real decoration of the Russian bath.

We have read in this article the most common type of stove, which is used for arranging a Russian bath. As you can see, the process of its construction is quite complicated and responsible. Therefore, do not rush to start work. Carefully read all the recommendations in this article, diagrams, photos and video.

Video

In the video provided, you can learn how to make a stove with a water boiler:

And in this video you can watch with the manufacture of the furnace 3 * 3.5 m:

If you want to do the work yourself, then you will also be interested to watch the following video:

Photo

Kamenka buller (buleryan)

Kamenka buller (buleryan)

Bath stove -amenica "Breneran"

Bath stove -amenica "Breneran"

Sayana Vitra Oven Termofor

Sayana Vitra Oven Termofor

Furnace for the Russian bath

Furnace for the Russian bath

From cast iron

From cast iron

In the steam sauna stove combined with cam Mr. in the waiting room

In the steam sauna stove combined with cam Mr. in the waiting room

Fireclay fencing of the furnace

Fireclay fencing of the furnace

Homemade stove-heater

Homemade stove-heater