Most of the home craftsmen often raise the question of how to make furniture on their own, but they are almost always not interested in the price of the issue, but in quality, reliability and the ability to get something unusual. There must always take into account the many factors and nuances that accompany the process.

Before you start making furniture yourself, you need to decide on the type of material and carefully study its features.

The choice of material

Before you make the furniture, you need to carefully select the material. Three options are commonly used: edged board, furniture board and chipboard.

The edging board is the most popular because of its physical dimensions. It is usually used as an auxiliary material, since the support system from it is ideal. With the right choice of wood, it has the most excellent strength properties, besides, it ideally lends itself to any kind of processing.

Laminated chipboard, on the contrary, is in 1st place among all, since it is characterized by low price, multivariate range and ease of operation. Usually used MDF, which is characterized by averages. It is quite simple to work, and it is possible to manufacture even a complex product in 1 day. But here it is necessary to take into account the fact that it will be almost impossible to make a figure with home equipment, and the areas not glued with piping also emit chemically harmful substances into the air. This option is usually used for the manufacture of budget options for furniture that serves not for beauty, but for use.

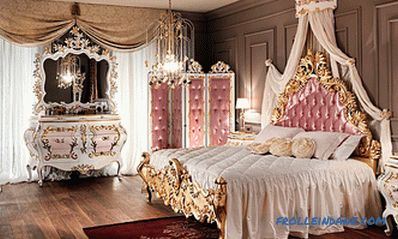

Products from a furniture board turn out strong and beautiful.

Furniture shield is the most reliable and durable material of all, but the high price does not even allow to get closer to one place. The material is very malleable, has no chemical contraindications, besides, anyone with standard tools can work with it. Because of the high price, it is usually used for the manufacture of products, which will then be visible to the eye, since it is inappropriate to make shelves in a niche from it. Due to the method of manufacturing, the material does not lose its strength indicators at all, and the variation of thickness plays at all a hand.

In addition to the standard, other options are used:

- Array. Here the price is really huge, and some experience will be required for working with it, since the wood in this condition is not particularly malleable.

- Aluminum frames. The combination of aluminum, plastic and glass is becoming more and more popular, since the structures are light and technological, but short-lived. Even the most elegant table based on aluminum will last no more than 30 years with good care.

- Fiberboard and plywood. Used as auxiliary materials, but every year they lose popularity. Even laminated plywood can not be compared in its characteristics with chipboard.

A set of tools is always standard:

Tools for making wooden furniture.

- Screwdriver. Serves as a screwdriver and a drill at the same time, and it is desirable to use a tool with a depth gauge.

- Jigsaw. Cutting materials, and as a cloth, it is desirable to use nail files that tear only from 1 side (everyone tears, but some from the 2nd).

- Hammer and staple nails.

- Rubber foot gaskets.

- Furniture screws.

- Iron and piping. Pasting open areas chipboard.

- Stain, varnish and brush. The final coating of edged boards and furniture panels.

A simple version and manufacturing process

Before you make any of the furniture yourself, you need to make a drawing, but in this case let it be a table, since it will be made easy, but all the basic elements will be affected. The chipboard will be used as a material, and the ratio of parameters will be maintained for clarity.

At the very beginning, you need to cut out a number of parts:

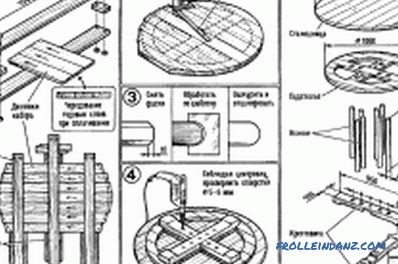

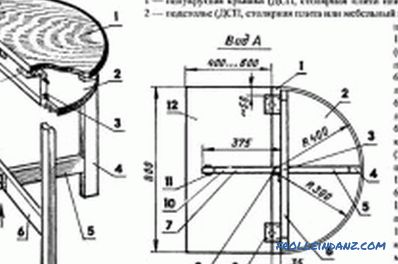

The design of the kitchen round table.

- Tabletop. You can use not only the shape shown in the drawing, but also any other (circle, square, rounded corners, a relief surface with the separation of a seat for each person sitting, etc.). It is cut primarily from the best segment of the plate.

- Upper and lower dressings. The principle of their work is excellent, but the length of the top is 100 mm less (1300 mm) than the length of the bottom. Lower, in turn, is equal to the table top (1400 mm).

- Wedges (2 pieces). They are needed for fixing the lower ligation.

- Sidewall (2 pcs.). Here it is necessary to take into account the growth of the highest family member, since not everyone will suit 710 mm. If the table is made personally for 1 person (computerized), then the ratio is selected as follows: height - 1 m, but not more than 80 cm (with a growth of 176, the table should be 76 cm, but with height 195 there will be only 80 cm).

- Thrust bearings (4 pcs.).Rubber linings are commonly used, but plastic and even chipboard can be used depending on preference. It is advisable to use soft materials, since this will reduce the noise level and adapt to the small unevenness of the floor.

After all the elements have been cut, they should be wiped with a damp sponge (never wet) to collect dust. After 20-30 minutes, you can continue the workflow for the manufacture of furniture.

At the very end, it only remains to assemble the structure, and there will be 2 embarrassing points that should be considered initially:

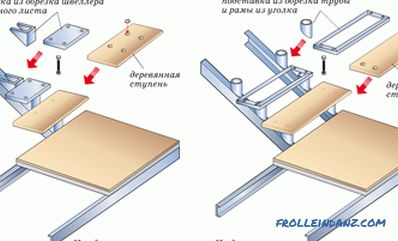

Table assembly scheme.

- Wedges are fixed with studs, which are worn on 2 sides and fixed with closed nuts. If this is not done, then inadvertently it will be possible to hurt the open metal, which can injure the skin.

- Installation of the table top is carried out on the dowels (dowels). For this, small (non-through) holes are made at the points of contact, after which a slightly slow-hardening glue is admitted to the very depth from 2 sides, and then the table top is installed. Without glue, it will also be good, but not so securely, so when carrying the legs may fall off.

Rubber pads are nailed onto staple nails (5 pieces each). The use of screws is unacceptable, since they have too large caps, which reduce the effect.

The basic principles of work

In the manufacture of furniture, several important factors must be considered at once:

- The quality of the support. The best support is 3 legs, since the surface in this case will never lose its balance on its own. Using 4 points of support reduces stability, but reduces risks. To compensate for this drawback, rubber pads are used.

- Strength of the material. If you make a small wall shelf for books, then it makes no sense to use heavy and durable plates, whereas for a sofa or a festive table you cannot use lightweight, inexpensive options. The material is selected for each time needs.

- Work with joints. When working with hand tools, bumps often remain, which is why it is better to give preference to electric. Convexity, if necessary, wipe with an electric plane in a matter of seconds. All joints should be carefully fitted and, if necessary, tightened aluminum furniture corners.

Even in cases where the work takes an unreasonable amount of time, you should not try to do something faster, because it will certainly lead to a crash. Complex designs are initially unreliable, therefore in furniture it is desirable to avoid small fragile details.

Anyone can, if they wish, make furniture for their home, but you need to stock up on tools and patience in advance.

The more accurate and thoughtful the approach, the more reliable the resulting construction will be.

Didn't find the answer in the article? More information on the topic:

-

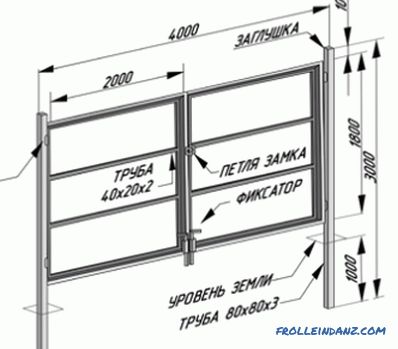

Making your own wooden gate

Making wooden doors with your own hands. Tools and materials necessary for the manufacture of wood gates. Sheathing and installation of wooden gates on a metal frame.