The frame is a traditional option for the construction of summer houses and small country houses. Today, the scope of the log has expanded considerably. From it build houses, baths, saunas, hotel complexes.

The basis of almost any wooden house is a blockhouse.

A log of both hardwood and softwood can be used to construct a structure. In order for the building to serve for a long time and during the operation there were no problems, the installation of the log house should be carried out according to all technologies and standards.

What to look for

The construction of wooden houses has a long history. Today, the popularity of log houses is increasing. The appearance of the log of the rounded log fits perfectly into the green landscapes of the site.

The first thing you should pay attention to is that not every type of wood can be used as a building material. The log house of logs is not built for one year, so the building material must be particularly durable and, importantly, affordable. These selection criteria, such as high quality and affordable price, include wood species today:

Types of trees used for the construction of a log house.

- pine;

- larch;

- willow;

- oak;

- aspen;

- birch.

A rounded log must have the required size. There are standards and norms that control the diameter of the log house, this indicator should be in the range of 20-26 cm. It should be controlled that the diameter should be the same along the entire length of the log.

As a result, choosing a frame for installation of a building, you will receive:

- the natural origin of the material and its environmental friendliness;

- very high heat capacity;

- attractive appearance;

- sufficiently high reliability of the design.

However, there are also disadvantages:

- the price is high, which is far from being available to everyone;

- without proper processing of the frame will not last for long;

- installation complexity.

Based on the main disadvantages and advantages, it can be noted that the choice of wood as a building material will depend only on personal preferences and financial possibilities. Installing a rounded log is a rather complicated process, so it is best to use the services of specialists. In order to carry out the entire installation of the house independently, it is necessary to study the subtleties of the construction of houses from rounded logs, methods of connection and subsequent processing of the structure.

Choice of the method of installation of the log house

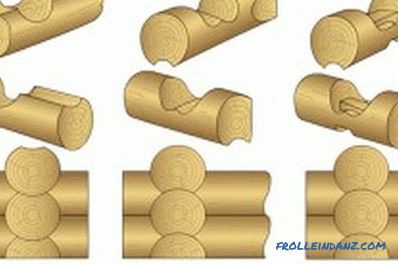

Connection options for logs in the log house.

To build a house, you need to make a project, this stage of work in the case of the construction of a wooden house is the main. It will be seen from the developed project which assembly method is best to choose. The classification of the installation of a log house may depend on such indicators:

- the layout of the house;

- the method of fastening between the logs;

- the logs, as well as their processing.

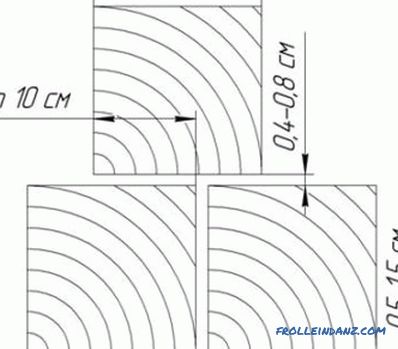

The layout of the structure may be different. The classic version is a rectangular or square structure, the more complex variants include the construction of figured buildings - semicircular, hexagonal. A round log can be held together in two most common ways:

- installation in a bowl;

- installation in a paw.

The main difference between these two methods of installation lies in the form of special grooves, which are formed to connect the logs together.

The connection in the bowl is characterized by the fact that all corners of the structure are protected from the effects of wind. But at the same time, the main disadvantage is a high consumption of wood, up to 4 m of logs can be spent on one crown.

A compound in a paw is characterized by inverse properties. Material consumption is minimized, with all corners left open and constantly exposed to wind currents.

Required tools

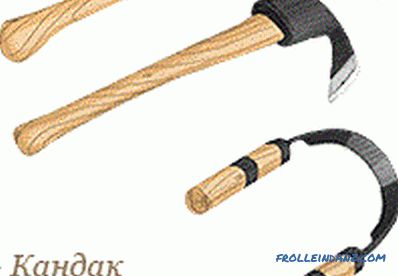

To work with wood, you need to prepare all the joinery tools. The main tools that will be needed during installation:

Tools for building a log house.

- brushes and rollers of different sizes for treating the material with antiseptic agents;

- hammers of different shapes and weights;

- saw with large teeth;

- Planer;

- The ax is large and small;

- Jigsaw manual or electric (the second option will provide faster work);

- chisels;

- chisels ;

- nail catchers;

- a drill with different drills;

- for measuring - level construction, tape measure, angle, pencil.

Installing a log house with your own hands

To build a house from a rounded log, you need skills and a sufficient amount of time.To carry out all the work correctly, the entire construction process should be divided into several main stages.

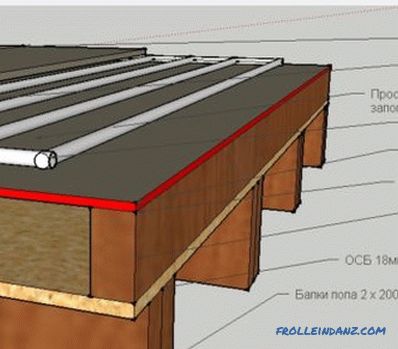

Preparing the ground and pouring the foundation for a wooden structure. Before the foundation is poured, it is necessary to accurately determine the material from which the walls will be erected, since a certain foundation is needed for each type of timber. The best option for the foundation will be tape. It is durable and fairly simple in operation. After the foundation has been in place for a month, you can proceed to the next stage.

A good waterproofing layer must be laid between the foundation and the wall.

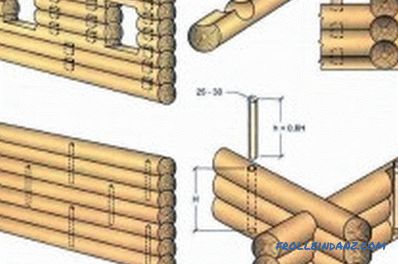

Scheme of assembly of a log from a rounded log on the nails.

For this purpose it is best to use roofing felt. The board is laid on the waterproofing layer. The first row of the log house will be laid on it. The minimum thickness of the starting board should be at least 5 cm. It is very important to lay a layer of tow between it and the first log house. This minimizes the presence of cold bridges.

In order for the first log house to lay on the board as tightly as possible, it is worth making a tool about 15 cm wide. After the first row of logs has been laid, you can proceed to the subsequent construction of the walls. Between each crown must be laid tow.

In addition to dressing at the corners of the house, all logs should be additionally reinforced with spikes. This mount can be done through every meter. If there is no such gain, the installation of log cabins will not be sufficiently stable.

The finished structure of the rounded timber must be at least one year old. This is necessary so that the whole structure gives the maximum shrinkage. It is precisely in the process of shrinking that the openings of doors and windows can be deformed, therefore it is impossible to install windows and doors.

Once the shrinkage of the house has ended, the caulking work should be done. This process involves the compaction of tow in all joints. Such a procedure should be carried out regularly at least once a year.

Installation of windows and doors should be carried out only after complete shrinkage of the house. In addition, in order to prevent damage to the window frame and doors in the front part of the opening, you need to install a special bar. To install it, you need to make grooves in the wooden house. To achieve the required strength, it is worth using a bar with a section of 50x50 mm. Such arrangement of the openings will prevent deformation. The window frame and door frame are subsequently attached to this bar.

Basic guidelines for the care of the construction of a rounded log

In order to protect the frame from the effects of the environment, it must be treated with antiseptic.

In order for such a building to last as long as possible, it is necessary to choose the right building material and carry out regular processing. Basic recommendations:

- Logs for logs should be made in winter. It is this winter hardening that makes wood more resistant to atmospheric influence in the future.

- All details of the design should be treated separately with antiseptic agents. They will prevent destruction processes such as wood rot.

- All joints between the crowns should be tightly rammed with tow. This will significantly increase the heat capacity of the entire structure.

- If the installation of logs is carried out using the method in the paw, it is worth further processing the corner joints. To do this, they are sheathed boards.

When constructing the roof, the truss structure with a wire must be fixed to 3-4 rows of a log house. This will make the structure more stable before a gust of wind. If cracks are found in logs, they need to be filled with tow and further processed with putties that prevent the ingress of moisture.

Didn't find the answer in the article? More information on the topic:

-

Tightening wooden floor by yourself

Step by step instructions on how to do the screed on the wooden floor with their own hands. Necessary for work tools and materials. The main stages of the workflow. Calculation of the mixture for the room.

-

How to lay the plywood on the screed

Laying plywood on the screed: preparatory work, applying primer on the screed, laying waterproofing. Technology and installation features of plywood on glue. Tools for the work.