To use wood for construction, it must first be properly prepared. To do this, apply the drying, which allows you to bring the material to the desired level of humidity. How to dry a tree, what methods will help best? Specialists recommend purchasing wood in finished form, as in the conditions of the workshop it is much easier and more qualitative to perform drying, but with your own hands it is not always possible to organize this process correctly. Although there are some simple methods that will allow to dry a small amount of wood for finishing the house.

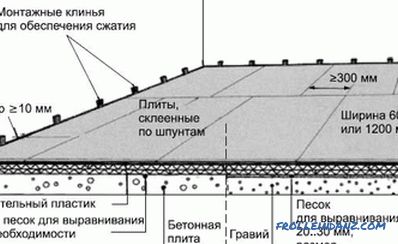

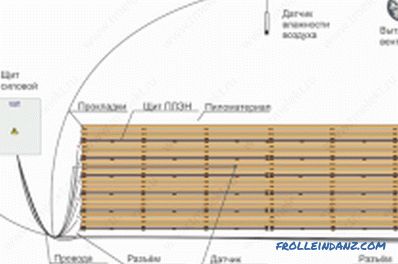

Scheme of wood drying in the drying chamber.

Rules for wood drying

Only dry wood is allowed for construction. The problem is that this material not only in its natural state contains a lot of moisture, but also absorbs it perfectly. If you take a damp tree for building a house, then, getting into drier conditions, it starts to shrink gradually, the structure shrinks. Such boards can be strongly deformed, cracks appear on the surface, the construction loses its strength and other qualities. The more harvesting, the slower the drying of wood. The process can take from a month to several years. For example, it may take up to 7 years to dry an oak board.

While drying a tree, moisture evaporates from the surface, while it moves from the depth of the wood to the surface, but the internal parts dry much more slowly . Natural moisture evaporates slowly, to speed up the process, it is recommended to use digestion and other methods, of which there are quite a few today. Some of them can be organized independently, but for others the conditions of the workshop are necessary.

Drying is carried out in 2 stages:

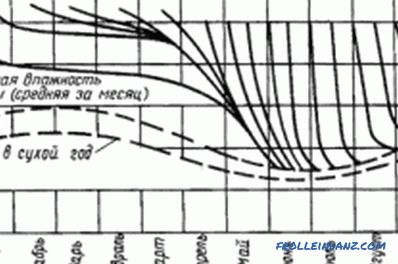

The duration of the atmospheric drying of coniferous sawn timber.

- First you need to bring the material to the level of moisture required for atmospheric drying.

- Finishing drying is carried out under the chosen conditions, the humidity should be brought to a level that is acceptable for construction or for use in other processes. If the tree is to be operated in open air conditions, the humidity level should be 12-18%. Usually, the material is dried under atmospheric conditions; drying at room temperature is no longer necessary. If the material will be used to finish the interior heated rooms, then the humidity level should not be more than 8-10%.

In order to accurately determine what level of humidity has been reached, it is necessary to use special equipment. These are convenient electric moisture meters that allow you to accurately calculate the percentage of drying. In some cases, moisture can be determined by sight, although professionals do not recommend using this method for construction. Dry wood chips are easily broken in the hand, and in wet wood they are compressed.

Drying under atmospheric conditions

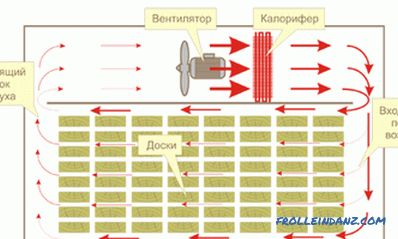

Gas dryer circuit.

Most often, the hands are drying under atmospheric conditions. To do this, you must first free up the site, clean the soil, make an excellent drainage around the perimeter. From the site it is necessary to remove all the chips, debris to prevent rotting boards and lumber. After this, the blanks are stacked on specially assembled flooring of the poles. It is necessary to form the first row with a slight slope, then cover it with dry boards. Next, a second row is formed and so on until the end. Top of the rain materials are also protected by boards.

If logs are used for drying, it is not recommended to remove the bark from them immediately, it will be an excellent reinforcement against cracking.

Drying up, such a tree is best to retain all its qualities and integrity. The ends of the logs must be lubricated with liquid glue, lime or sodium chloride solution. This is done in order to protect materials from rotting. But the upper edge must be protected from precipitation.

Atmospheric drying allows you to remove about 75% of all moisture from materials. The duration of the process depends on the type of wood, weather conditions.

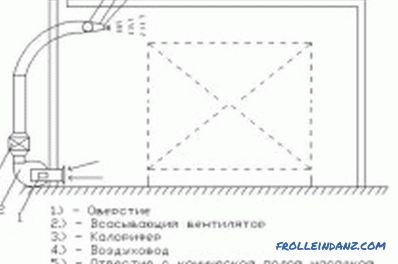

Infrared drying of wood.

Deciduous and coniferous soft breeds require about 1-2 years to dry, hardwood hardwood varieties require about 2 times more, but it may take 7 years to dry completely. On average, a year by this method, wood dries by 1 cm.

Home drying is carried out before construction begins. About a year or two is recommended to prepare the site and leave the material to dry. If you need to dry only a couple of boards, then you can use an attic or an open balcony, well lit by the sun.

Self-drying methods

A variety of methods can be used for drying wood at home, they are all simple and do not require sophisticated equipment. For example, drying with the use of newspapers is suitable only for small volumes. Boards are wrapped in a dry newspaper, then in a plastic bag. After about 8 hours, the film unfolds, the wet newspaper is replaced with a new one. It will take about a month to dry, but it all depends on the type of wood. The number of newspapers in the package can not be made too large, because the boards just cracked. It is important to wrap the film tightly so that air does not get inside.

Straw can be used instead of newspapers for drying. Boards are laid dry straw, and then stacked under a canopy. If there are dry sawdust, you can use them for lining. Change every day straw or sawdust is not required.

Scheme of natural wood drying.

One of the most effective methods is digestion. Boards are placed in a large container filled with water. After that, for 2-3 hours they are boiled, laid out in an open space for drying.

This allows you to quickly remove the natural moisture. It is possible to decompose the treated boards on a flat surface in the shed, but the room should not be heated, be too damp.

Specialist Tips

When drying the wood, you must remember that the duration of the process depends on which breed will be used. For example, oak boards can dry for a long time, this process in natural conditions is delayed for 7 years. Some rocks crack during drying, and this only degrades the quality of the surface. If you are not sure that everything will be done correctly, then it is better to purchase ready-made wood with the necessary level of humidity.

Experts advise using 2 methods of drying the tree:

- The logs are sanded in the middle part, but the bark is left at the ends, the width of this tape is about 100 mm.

- The bark is not removed, and cuttings are made across the trunk to provide air access. Along the bark is not cut, in this case it acts as an excellent tightening yoke.

During drying, it is necessary to be guided by what wood species and how they react to the drying process:

- Do not crack alder, linden, birch, aspen, poplar during drying . The surface of the blanks remains smooth and of high quality.

- To a small extent, such wood species as larch, spruce, cedar, pine, and fir are cracking. They are used for construction often, as they have all the necessary characteristics. This material is durable, it makes even great loads, has a pleasant aroma and color.

- When drying, beech, hornbeam, maple, ash strongly crack. When choosing this type of wood, it is best to take already dried and finished boards that have undergone factory processing, since it is difficult to prepare them with your own hands, a large percentage of waste is obtained.

Various methods are applicable for drying wood. In the process of drying, the boards can not only lose some of the volume (moisture in the wood is abundant), but can also be deformed and covered with cracks. And this is already unacceptable for building structures. That is why experts advise a proper amount of time to devote to the preparation of the material.

Didn't find the answer in the article? More information on the topic: