When carrying out repairs in an apartment with a complete replacement of plumbing, its owners often face the problem of securing the equipment installed in the bathroom. This is particularly true of the working procedures for installing a new bathroom, the specificity of which is determined by many factors, including the material of the product and its texture. So, a traditional cast-iron bath with a significant weight is best to be installed according to a long-established method, which assumes its reliable support on the included and adjustable feet.

For lighter acrylic baths, for example, additional fastening is required, ensuring its secure fixation and uniform distribution of loads across the body. In our article we will consider in detail the installation features of each of the samples of this sanitary ware.

Methods of fixing baths

Feet for steel bath

Feet for steel bath

Anyone who wants to figure out how to strengthen the bath so as not to falter - we advise, first of all, to decide on the material from which it is made, since this is largely the decisive way to install it.

When choosing a product, one often encounters the following options:

- classic cast iron bath;

- acrylic bath;

- steel bath.

For each of the samples of these products a special mounting method should be used, only for it a suitable mounting method, taking into account the particular features of the wall relief of the bathroom itself.

Feet for acrylic bath

Feet for acrylic bath

Cast iron baths are sufficiently resistant because of their significant masses, so that their installation is permissible anywhere in the room. Usually such baths are installed on standard legs, which are supplied with the product and are securely fixed on its body with the help of special steel wedges or bolts. As an additional fastener, a pre-laid base of brick may be used, or corners fixed on a wall (in the case of a base of brick, its body may also be located not closely against the walls).

A steel bath is best placed at several points of support, so that it should be located directly against the wall. Since the legs included in its set do not provide the required fixation reliability, a special brick podium is often used to increase the stability of the product.

The following methods can be used to fasten a steel bath:

- use of foam that seals the junction with the wall and simultaneously strengthens the contact area;

- installation on walls of special metal profiles that provide additional support;

- and, finally, the usual tie-in into the wall.

To securely secure and ensure even distribution of loads, it is best to place the acrylic bath on the same brick podium or use a special metal frame for this purpose.

Consider each of the bath attachment methods discussed in this chapter in more detail.

Mounting foam

Using mounting foam

Using mounting foam

Using mounting foam to fix bath is the easiest and most affordable method of its simultaneous fixing on the floor and walls. When implementing this method, the bath product is first set at the place and height with the help of adjustable legs so that there is a gap of about 0.75-1.5 cm at the walls, and then filled to the brim with water.

After that, it will be possible to begin sealing the gaps between the bath body and the adjacent walls of the room, as well as between its legs and the floor with foam.

Sealing foam tends to expand as it dries, so its use must be strictly metered. Otherwise, there may be undesirable deformations of the structure, reducing the reliability of its fixation. Despite the fact that the time of "setting" of the assembly foam is about 12-35 hours, it will be possible to start the work on wall finishing in about 6 hours.

Using the brick frame

Using the brick frame

Using the brick frame

Brick frame is most often used in cases where you decide to fix the bath without the help of legs and to ensure an even distribution of loads along the entire perimeter of the support. With this method of installation, options for laying out the frame are possible both along the bathroom and across it.

In the case of transverse positioning, the bath must rest directly on the brick, which will require additional fixing of the frame to the walls using the corners of metal (steel or aluminum).At the same time, the prepared corners are fixed with dowels on the wall so that the free edges of the bath have additional support, and it does not swing when pressed.

Installing the bath on bricks

Installing the bath on bricks

With longitudinal laying, something like a trough is formed into which placed bathing product. The gap or cavity formed between the walls of such a base and the bathroom itself must be sealed with foam, which also contributes to increasing the reliability of its mounting. In the case of laying out the front wall to the very top, it is possible to completely hide the body of the bath, thus preparing the ground for subsequent lining with ceramic tiles.

Brick screen

Brick screen

When performing these works, be sure to provide a small observation hole necessary to ensure access to siphon. When finishing this hole can be closed with a piece of drywall or by installing a small plastic door. In the case when you are planning to finish the walls with ceramic tiles - a finished screen can be used as the front panel of such a base.

Installation on a metal frame

This method of fastening baths is mainly used for the installation of acrylic products, complete with which, as a rule, a finished steel frame is already provided ( in its absence, this accessory can always be purchased separately or made independently). In the process of installing such a bath, the mounting or guiding rails of the frame are first attached to its bottom with self-tapping screws (note that they are mounted in specially designated areas with thickenings). And then the supplied feet are mounted on bolts fixed in this way.

Additional support

Additional support

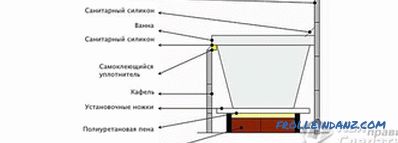

After fixing the legs, the bath should be put in place and the touch points should be marked with its body the walls of the room, after which special strips are mounted at these points, providing additional support.

It is necessary to leave a small gap between the bar and the side (no more than 2-4 mm), taking into account the expansion of the bath after filling it with water.

Insertion of the bath in a niche

Insertion in a niche

Insertion in a niche

In small apartments, very often a situation arises when the bathtub is placed with great difficulty in the space reserved for it, which, on the one hand, considerably complicates its installation and, on the other hand, enables rigid and reliable fixation in the bathroom niche .

To insert and rigidly fix the bath, you will need to prepare slots on each side of the wall along the thickness of the product’s edge (for this purpose, you can use a hammer drill or a grinder). The grooves of the edges or cups of the bathtub prepared with their help should be inserted with a slight “tightness”, which guarantees maximum rigidity due to the complete absence of backlash.

In case of insufficient stiffness of the supplied legs, you can further strengthen the fixing of the bath by using special transverse profiles that serve as supports for its cuffs.

Video

How you can set a bath in the strobe, see below: