Many people think that wooden houses do not require insulation. As is known, their thermal conductivity is such that the walls are able to retain heat even in severe frosts. However, this is not always the case. There are situations when a person has purchased a log house, and that from time to time it fails in terms of thermal insulation. The fact is that the design of log houses is such that they can pass cold air through the cracks. And it is not at all necessary that these slots will be located on the walls. This may be the floor, and the ceiling, etc.

The insulation by a caulk of a wooden house is done by plugging the gaps between the logs inside and outside the house.

In this case it is worth talking about warming the house from a log. Any log house during the construction process may not have defects that will eventually crawl out, leading to discomfort inside the room. The house of logs is much better than brick in terms of thermal insulation, so often here you should not use a huge amount of insulation.

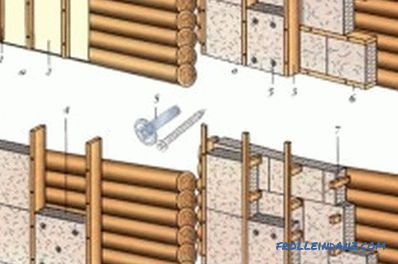

Technology for warming a log house

A scheme for warming wooden walls with various methods.

Most often, when cold air appears inside the room, which is a log house, people think about how to warm it. In fact, the technology here is quite simple. First, you should try using the standard methods of warming the floor or ceiling, since it is from there that cold air can flow. If this measure does not help, then you can move on to the option that is to warm the outside of the log house. This method of insulation is considered the easiest and most effective.

It must always be remembered that work related to the insulation of a house should be carried out only after it has passed the final shrinkage. Shrinkage takes about a year for a new building. Only after that you need to lay insulation. For a start, it is worthwhile to cut the entire structure. This will immediately close the large cracks, from which cold air enters the house. In some cases, this measure may be the only one that will solve all problems with cold air. Caulk need those gaps that are large in size.

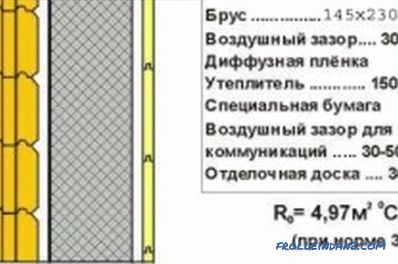

Insulated wall construction for an average climatic zone.

Sometimes it's hard to find them, so you have to use a variety of search methods for this. You can simply bring a candle to the house, if in some place the fire deviates towards the house, then there is definitely a gap. However, this method is not always justified, since it takes an enormous amount of time and effort. Most often it is best to check the tightness in frosty weather, when frost begins to fall on the wall. It is in those places where it was formed, and there is a leak of warm air, more precisely, the flow of cold.

For the caulking process, you will need the following tool:

- caulking iron;

- possibly a spatula;

- insulation that can act as a tow, jute or rolled material.

All the work in this case comes down to the fact that with the help of a special tool, which is called a caulker, the caulking of cracks outside the house is made. It uses one of those types of materials that have been described above.

Ventilated facade device

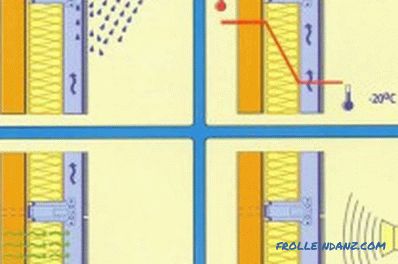

Behavior of the ventilated facade in different weather conditions.

It is the ventilated facade that is most relevant in this case, since it will ensure unhindered air circulation through the walls of the building. For a wooden house it is very important, because otherwise, in the near future, mold or fungus can form on its surface or microorganisms begin to develop. All this leads to a fairly rapid decay of the material.

Due to the fact that the ventilated facade has such a structure, it allows the house to breathe. Do not forget that the walls of the log house must first be treated with an antiseptic. This substance will protect them for years from mold and microorganisms. Antiseptics are applied around the perimeter of the building on the walls. They can be both transparent and translucent. It all depends on the choice of each individual. After the walls are processed, you can begin to arrange the crates of the future facade. In this case, a very good solution would be the use of wooden bars as the main material of the batten.

At the same time, they should also be treated with a special compound that will perfectly protect the tree from the development of various microorganisms. They must be nailed upright. Nails can be used for fastening, but they must be long enough to make the structure stiff. The distance between the individual bars should be the width of the insulation minus a few centimeters.These additional centimeters are necessary for attaching insulation to the batten.

In this case, you can use almost any material as a heater, but mineral wool, which is made in the form of slabs, is best suited for this purpose. They have a rather dense structure, do not burn and do not let moisture through. The thickness of the plates is selected in accordance with those parameters of the house.

Practical recommendations

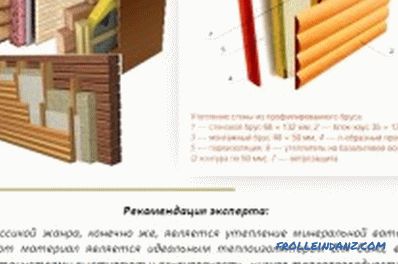

Warming scheme for a log house outside.

It is very important to remember that when the walls of a log house are warmed outside, there are various gaps between the wall and the insulation itself. They will contribute to the formation of cold zones. In order to eliminate this phenomenon, it is necessary to use additional insulation, which will be inserted between the plates of mineral wool and the wall of the house. In this case, you can completely eliminate the formation of cold bridges.

Slabs of mineral wool must be put under the crate. At the same time, all the plates between themselves should stand tight enough to also eliminate the formation of cold bridges. At the same time it is necessary to mount a heater from the bottom up. To begin with, it is necessary to equip the starting level, in relation to which the work related to wall insulation outside will be carried out. All plates of mineral wool are laid on it. This level is necessary in order to ensure the even arrangement of all rows of insulation.

After that, waterproofing should be applied to the mineral wool plates themselves. In this case, it is best to use membrane waterproofing. Benefit now it can be purchased without much difficulty in any specialty store. It is very important at this stage of work to choose the right waterproofing. It should allow the walls to breathe, that is, not to let the moisture inside the structure of the heat-insulating layer, but at the same time let it out. Membrane materials allow to achieve this result.

Options for warming a log house.

Next, another layer of the battens is installed on top of the same bars that were used previously. After that, the house can be finished with any facing material. In this case, the most successful solution is to finish the house with siding. This may be ordinary vinyl siding, but it is best to imitate the surface of the wood. The overall picture will look much more natural.

Some features

Warming the house outside is a necessary measure that is used only as a last resort.

If we are talking about a log house, then it is best to try to pre-warm the house from the inside.

In this case, we are talking about warming the floor, ceiling, walls, and so on. If you use insulation outside, the house can lose its original appearance. Of course, natural wood will look much more spectacular than ordinary siding, which is made under this material. So, before you do the insulation of the house outside, you should try to warm it from the inside. This is done quite simply. All the same materials are used. However, the technology is slightly different from the one described above.

Thus, at the present time, weatherization of the house, which is made of logs, is a whole problem. Here it is worthwhile to use the most varied methods of getting out of the situation in order to cause the least damage to the surface of the building. Aesthetics above all. However, if we are talking about insulation outside, then it is imperative to follow the instructions that were presented above. This will allow all the work to be done as efficiently and quickly as possible. As you know, the process of home insulation outside is quite simple. To do this, use the simplest materials that can be purchased on virtually any construction market, which also simplifies the work.

Didn't find the answer in the article? More information on the topic:

-

Wooden doors for your own home

Recommendations for how to make wooden doors with their own hands. Options for interior doors. What materials can be used for this product. Installation of the canvas.