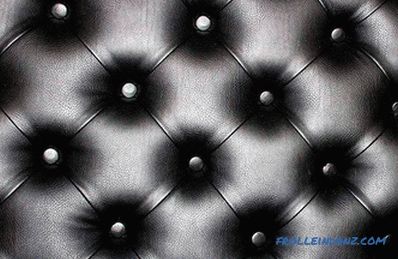

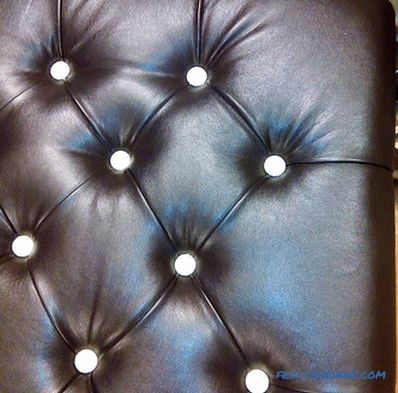

Classics of France. So it is possible to briefly characterize the carriage fastener. In this way today, sofas, chairs, armchairs, headboards and bedside tables are trimmed, walls are lined with styling cafes, lounges and other rooms. This method allows you to visually increase the height of the ceiling, thereby achieving a beautiful optical effect. For these purposes, traditionally used plain furniture fabric, leather and eco-leather.

In this article, we will talk about how the carriage stitch is made with your own hands. You will also learn about the advantages and disadvantages of this technology. Step-by-step instructions will be provided with photos for making capitone, as well as separate instructions for making buttons for it. In addition, we will briefly look into history and find out how this upholstery technique actually appeared.

Go back in time

Chesterfield sofa - timeless classic

Chesterfield sofa - timeless classic

Car upholstery technology originates in the middle of the nineteenth century. She knocked royal carriages, so Captain immediately began to be associated with wealth, luxury and chic.

In those days, the decoration of upholstered furniture, and sometimes walls, was found in almost every rich house. Later, this technology is a thing of the past, but today it is becoming fashionable again and is becoming more and more popular.

In a modern interior

A carriage coupler in a modern interior

A carriage coupler in a modern interior

Today this upholstery as in the past, it is found in the luxurious homes of wealthy people. Although, if you make a little effort, time and money, then every craftsman will be able to make a carriage fastener.

There are three types of this screed:

- a classic diamond-shaped;

- square;

- a modern complex screed with varying geometry from floor to ceiling.

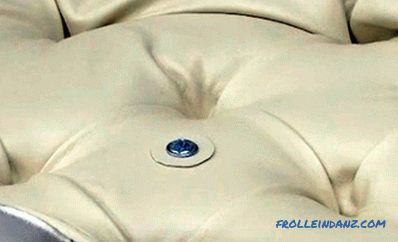

The chic and nobility of the screed is achieved, of course, at the expense of buttons. They can be very different, but we'll talk about this a little later.

Utyazhka buttons forms a carriage coupler

Utyazhka buttons forms a carriage coupler

A distinctive feature of the captain - the characteristic folds that pass between the buttons, with the usual utyazhku any absent. A diamond can have a different depth and size. These figures depend on the thickness of the foam.

A traditional capitone or carriage fastener

A traditional capitone or carriage fastener

It is worth noting that it is much easier to perform a button down. You need to know the technology to create beautiful folds. This will be discussed later.

Advantages

Advantages of the four-sided carriage

Advantages of the four-sided carriage

As mentioned above, the four-sided carriage looks expensive and elegant. But is it practical? What are its benefits? It should be noted that the captain allows you to make an individual selection of fabric or leather.

In addition, you can choose the same design for beds and poufs or for sofas and chairs, etc. Another significant plus is the ability to choose colors according to the interior palette.

It is easy to care for the decorative surface. If you decide to make a wall in the carriage upholstery, then it will play the role of additional noise insulation.

Selection of fabric and buttons

Variety of fabrics and buttons

Variety of fabrics and buttons

Of course, silk and taffeta would look good, but these fabrics are very thin and will not withstand the pressure of buttons or nails. The appearance of the headboard, pouf or sofa of such fabrics will quickly lose its appeal.

The thickness of the elastic lining is very important, because the beauty of the geometry of the pattern, which will be the result, depends on it.

When choosing studs, consider the interior design of the room. Furniture buttons look better on the carriage stitch, made in a large room. Furniture nails with decorations and decorative coatings look great. They will give the finished product even more sophistication and luxury.

The durability of a ottoman or a bed, or a sofa, or a wall depends on the quality of leather, fabric or eco-leather. And here comes the conclusion: if you want to get a durable product in the final result, then you should not save on upholstery.

You can choose one of the following fabrics:

- chenille is a durable natural material;

- jacquard - has a large embossed pattern, holds folds well and looks luxurious ;

- natural leather is durable and durable;

- flock is a fabric with a nap, there is a rich color palette;

- velor is also called velvet fabric; due to its plasticity, deep folds can be made ;

- Faux leather - wear-resistant, fits well in the folds and perfectly keeps its shape.

Independent production of buttons

You can also make buttons yourself

You can also make buttons yourself

If you can not pick up the buttons to match the main fabric or leather, you can make them yourself.For this, you will need blanks and leather / upholstery fabric with a margin.

Do not buy a button with a plastic eyelet: it will not withstand the stresses and if it is not in the process of manufacturing the capitone, then during operation it will necessarily burst. Buy only with a metal loop.

To save money, it is better to buy the most ordinary smooth metal buttons, since blanks intended for plating are expensive.

| Production of buttons | |

| | First you need to cut off a small striped fabric / leather. |

| | Then, a blank for the button is made from this strip, that is, a rectangle is cut out. |

| | After the corners of the resulting rectangle are rounded. The circle must be 2 times larger than the button. |

| | So this should be a piece of leather / fabric under the button. The advantage of the skin is that its edges are not showered, which is not true of the fabric. |

| | A thick thick thread is taken so that it does not come off in the process of work, and tucks into a needle. Then the thread is folded twice and a knot is made at the end. It should be a little back from the edge and perform small stitches in a circle. |

| | There should be some kind of cap in which a button is inserted. |

| | Then the thread is tightened. It is necessary to fasten the thread, and the sheathed metal button is ready. |

| | It looks like a smooth edge and a homemade button looks almost identical to the factory one. |

| | From the inside, of course, the button is not so attractive, as there is an accordion. |

Materials and tools

What you need to make a capiton

What you need to make a capiton

To begin with, you should purchase all the necessary material and prepare the tool. Materials for production:

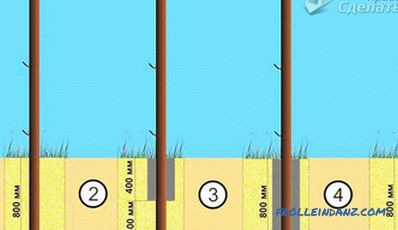

- Plywood will act as a base, it all depends on whether it will be - the sidewall or headboard, wall.

- Foam, corresponding to the shape and size of plywood and having a thickness of 5 cm.

- Fabric / leather / eco-leather 0.5 m wider and longer than plywood, add 30 cm to the buttons, if you have to sheathe The amount of material depends on the report of the figure, the smaller it is, the greater the consumption, and vice versa.

- Metal buttons.

- Foam adhesive.

- A cut of a sintepon repeating the shape of foam rubber and plywood. They need to cover the foam.

From the tools you will need:

- furniture stapler, best pneumatic;

- button fastening cord;

- crochet hook;

- a sharp knife;

- a drill for drilling holes in plywood;

- a drill with a tip digital.

Screed manufacturing processes are carried out in a matter of minutes if you have a special tool. You can learn about the principle of its work and features from the video we offer.

Video: features of the manufacture of the four-face carriage

Step-by-step instruction

Step-by-step instruction for the manufacture of the four-carriage tie 11

Step-by-step instruction for the manufacture of the four-carriage tie 11

In order for you to be able to complete the carriage screed yourself, we suggest that you consider step by step instructions with photos of this process. After getting acquainted with it, you will also be able to view additional videos on how to make a captain using another technology. All details can be seen in the table:

| Production Instructions | ||

| | First What you need to do after cutting the plywood of the desired shape and size is to mark up and make holes in it. | |

| | Then glue is applied to the plywood. | |

| | Foam adhesive is attached. | |

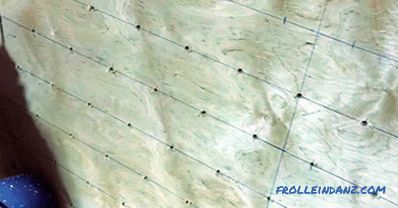

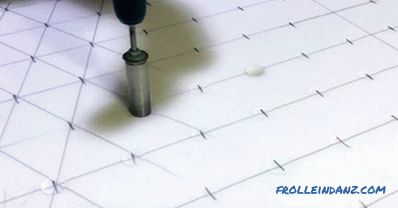

| | The screed marks on foam rubber are made using a simple pencil. The marker can break into the fabric, so that the upholstery will lose its appeal. | |

| | Then the holes are drilled through with a digivend drill. | |

| | Surplus foam is removed. | |

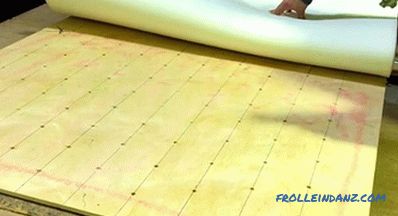

| | A synthetic winterizer is laid over the foam rubber. | |

| | The synthetic winterizer is glued with foam rubber glue. | |

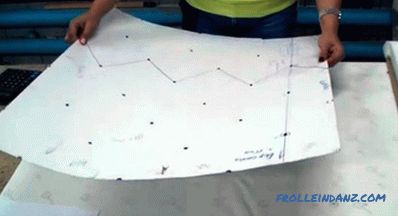

| | Make markup on fabric / leather. We retreat from the edge in width to the first fitting + 7.5 cm for the stock. | |

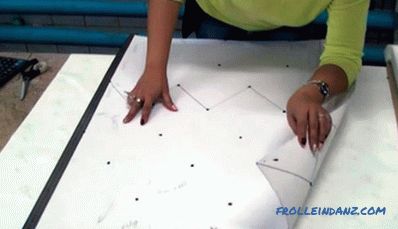

| | Next you need to take a stencil prepared in advance from cardboard with holes. It is applied on the wrong side of the fabric / leather. | |

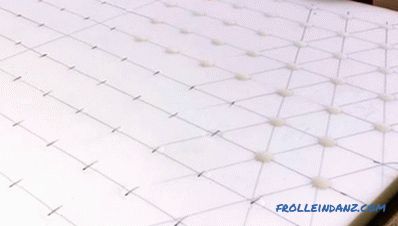

| | Markup A check is performed on the first marked point on the fabric / leather. On all sides, the indentation of the fabric / skin from the edge to the marks should be the same - the length from the edge to the first dressing should be + 7.5 cm. > We arrange points | We put points. |

| | We insert threads into all marked points. | |

| | Now we pull in the first row of threads with a needle or a special hook through the foam rubber and plywood and beat it with a stapler. | |

| | Then we twist the fabric / skin and insert the next row of threads, lay out the folds and beat the threads with a stapler. If the pattern and markings are made correctly, then the fabric will be enough to lay beautiful folds. To avoid skewing and correctly lay the folds, you should lay them gradually, from row to row. | |

| | Straighten wrinkles conveniently with a special stick. After the series is completed, proceed to the next. | |

| | Begin fixing a series of screeds from the middle. In this case, the fabric does not pull over, and the finished capiton upholstery will look very attractive. Before you fasten the thread with a stapler, you should carefully straighten the folds. | |

| | We check the product so that all the diagonals are even, correct the folds, if there is such a need. | |

| | We insert and fix several buttons. Buttons can also be inserted along the edges. But before the folds are fixed. | |

| | We perform the shaping of the side folds. | |

| | We fix the opposite crease, which will result in a perfectly smooth edge. | |

| | After all the extreme folds have been laid, a corner should be fixed. With proper calculation of the material and fixing the screeds, at this stage there will be no difficulties. | |

| | Ready corner. The final consolidation of the edge. | |

| | The ready capiton screed made using this technology looks very attractive. It is worth noting that the process of its manufacture is not so complicated. Most of the time it takes to prepare materials and markup, while screed is a fascinating and not so complicated process. |

A little time, patience and investment and your home will turn into a beautiful possession of the count family. For clarity, we suggest you view a few more techniques of making capitone in video.

Video: Capone making options

Photos