Most modern kitchens have a piece of furniture such as a stool. This is a very convenient, useful thing, which takes up very little space, which, with small sizes of typical kitchens, is a rather valuable quality. Making a stool with your own hands is easy even if the master has minimal working skills. The main thing is to carefully consider the preparation of details and the execution of measurements.

The stool is a compact but very convenient element of the kitchen interior.

Many residents of small apartments prefer to use something more mobile instead of a chair, and a stool with their own hands will fit perfectly well. Those who want to make a stool on their own, as a rule, do not face any difficulties, but having a good instruction manual and carrying it carefully will not be superfluous to carry out its items.

Tips for beginners

If you decide to make yourself a chair or stool for your own kitchen, but do not yet have experience in working wood, try to follow some tips while working.

Tools for making stools.

It is not necessary to undertake the implementation of groove-thorn connections. This will require not only good work skills, but also great accuracy at run time, otherwise, instead of a chair or stool, you’ll get a tottering thing. For such compounds can be taken only if you have the necessary skills.

The stool is usually a mobile thing that is constantly moved around the apartment (for example, the chair is less convenient in this respect). Therefore, it is not necessary to use chipboard in its manufacture - its edges are quickly destroyed, especially if the material is exposed to moisture. The chipboard and other fasteners are very poorly adhered to the chipboard.

Materials for making stools

In modern construction markets, furniture is offered in different forms and types, for example, you can choose a folding chair or a simple one. Materials for the manufacture of furniture can also be selected different. Ordinary furniture such as a table or chair can be made of wooden materials - plywood, OSB or chipboard, plastic, metal, and sometimes more exotic materials - like stone or glass.

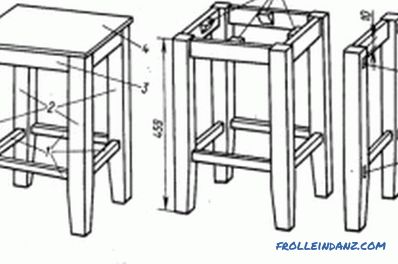

Design scheme of a wooden stool.

For making a stool with your own hands, it is better to choose ordinary wood, that is, wooden materials.

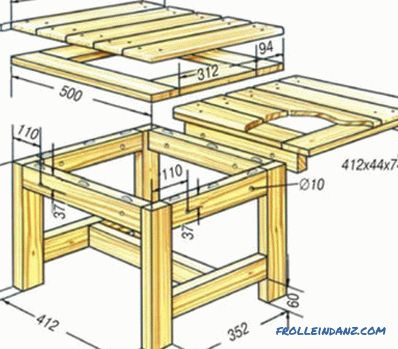

For example, you can take a stool that is reliable and uncomplicated in the design, consisting of three elements: legs, a seat, and elements connecting them. Before you make a stool, prepare everything you need for this. For its manufacture you will need:

- a bar for legs with a section of 30x30 mm;

- two boards of 145x300 mm with a thickness of 20-25 mm;

- sandpaper;

- wood glue;

- plywood 12 mm thick;

- acrylic lacquer;

- 40 mm long screws - 24 pcs.

Tools for making stools

The work should use only suitable tools and devices:

- hacksaw with fine teeth;

- curly screwdriver;

- ruler, angle;

- electric drill and drill bit to it;

- construction pencil;

- varnish brush.

Tools should be chosen only convenient and high-quality - then the work will be a pleasure, and the product itself will turn out beautiful and will be able to serve for a long time.

How to make a stool: stages of work performance

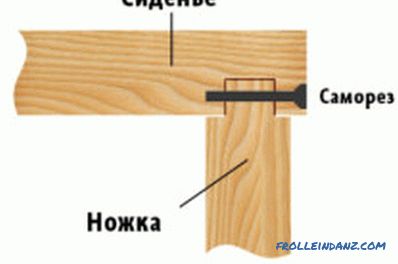

The scheme of fastening the legs of the stool.

The work instruction helps the master to save time to think about actions and not to make a mistake even with a little experience. To make a stool, to begin with, measure and saw off 4 pieces of a wooden bar, each one should be 430 mm in length. These will be the legs for the stool.

Now from the board with a thickness of 20-25 mm make blanks for the seat - there should be two of them, width - 145 mm, length - 300 mm. If desired, the seat can be made solid, if you can find a good, suitable board 300 mm wide. But the majority of house craftsmen try to use cutting boards, especially in cases where they remained, for example, from repair. The more serious thing is that they will not work out anymore, it is a pity to throw it away, but it is always pleasant to make a piece of useful furniture out of use, at first glance, scraps. Neither the quality of the stool, nor its appearance will suffer, if you collect it from pieces - you just need to do everything correctly.

Make the connecting plates of plywood - the stability of the finished product will largely depend on them. The size of the plates should be 100x270 mm. On the wide sides of the plates, cut two slots with dimensions 12x50 mm each. Each of the grooves must retreat from the edges of the part by 30 mm - this will be the thickness of the leg of the stool. We assemble the parts prepared in this way into the box - we get a bonding frame for the stool.

The legs and seat should be attached to the frame with screws. To do this, you need to pre-drill the guide holes. Before tightening the screws for greater reliability, place the joints on the joints with glue - you can use PVA.

If you want to give the stool a more stylish look, the edges of the parts are smoothed out - chamfering does not take long, and the product takes on a completely different appearance.

The resulting structure must be carefully processed with emery paper. This can be done both manually and with the use of a sander. First, it is necessary to carry out the treatment with coarse-grained paper No. 100-120, then process the result of a smaller one - No. 300-320.

Do not grind parts before assembly. When processing a stool in an already assembled form, all minor inconsistencies of parts are smoothed, and if such an operation is performed on the details in advance, it will be made almost empty. When assembling, small chips and other surface defects will inevitably appear, which will have to be smoothed over again, otherwise the product will look sloppy, ugly.

When grinding is over, coat the stool with clear lacquer in 2-3 layers. Before applying each of the layers should wait for the previous well dried.

Approximately the same way you can make a simple chair, you just need to make a back too. When working do not forget about the need to comply with safety regulations. In order not to get splinters and cuts, do not be lazy to wear gloves.

Didn't find the answer in the article? More information on the topic:

-

How to repair the stools with your own hands

Do-it-yourself stool repair: basic repair options for individual parts. Repair legs: installation with glue; thread restoration and improvement of the old thread. How to repair a seat.