One of the most important stages of work during the construction of a log house is the processing of a log house, that is, its polishing. This operation should be carried out on a mandatory basis, because unpolished logs have residual bark, which will eventually darken and rot. This will lead not only to the loss of the attractive appearance of the house, but also to a decrease in its service life.

After the log house has been built, uncleaned areas of bark remain on the logs, which will begin to darken over time, so the log house needs to be ground.

Grinding technology must be carried out according to certain rules and regulations. Therefore, further will be considered, how and how the log house is ground by hand.

When is it better to start grinding a log house?

At the time of processing the wood into a rounded log, the wood is still damp (it has natural moisture). While the wood has not dried up, polishing does not make sense, because its surface will ruffle even more. The most suitable time for polishing is 10-12 months after the construction of a log house, before processing the wood with a finishing coating.

Before carrying out grinding work, the house should be already closed. This condition must be strictly observed, because otherwise all finishing works will not have the required efficiency. Sometimes the logs have time to darken. In this case, they must first be treated with a special bleach with antiseptic properties. After the surface is dry, you can begin to process it.

If during the week after grinding you do not treat the surface of the log house with a paint coating or antiseptic, then the wood will darken. In this case, the entire processing process will need to start over. In order to achieve the same shade of a log house, finishing should be done no later than 4 days after grinding.

What is the best way to grind a log house?

The ideal option for machining a log house is a grinder.

Today on the market of construction tools you can find almost any equipment that will significantly facilitate the execution of an operation. No exception is the grinding of the house from the log. But not every tool will cope with this work equally well.

In order for grinding work to move faster, and their result was of high quality, the power tool used must be of sufficient power and have a small weight. Grinders available on the market do an excellent job with the processing of wooden building materials that have a flat surface. However, grinding a log house involves the processing of semi-circular wood. Belt sanders do not do so well with this task.

The best option is to use the grinder with a special sanding nozzle, which is a disc with sandpaper glued in the form of petals. At the same time, in hard-to-reach places, the processing of a log can be done with a chisel. The grinder, which will be used for grinding, should have a small weight and a power of at least 0.85 kW. It is recommended to buy such a tool from well-known brands (Bosh, Makita, Interskol). In this case, you can be completely confident in its reliability and durability.

Grinding steps for a log house

A grinder with a grinding nozzle can also be used to machine a log house.

For independent performance of these works, you need to prepare the following tools and materials:

- Bulgarian with a grinding nozzle;

- sandpaper of a different fraction;

- chisel.

The grinding of the log is performed in several stages: This allows you to remove the top layer of wood. At the same time, a pile is formed on the treated surface.

Thin tips should be used to process difficult-to-reach areas. It is best to use plastic nozzles, which, unlike rubber, are more durable and are somewhat cheaper. The most inaccessible places are the joining sections of logs in the corners of the house. Here it will be inexpedient to use a hand power tool. In this case, it is recommended to use a chisel with a cutting element width of about 2 cm.

Grind a log house without haste, in the right direction (along wood fibers).

There is no need to exert excessive effort, since the entire processing process should be smooth.

Grinding the ends of the log house with your own hands

Grinding the ends of the log house should be done carefully using a grinder with a grinding nozzle.

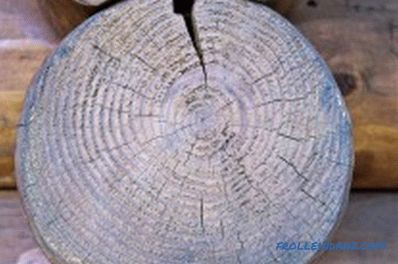

The ends of the house from a rounded log are most susceptible to the negative influence of the external environment. They very quickly absorb moisture, and at their finishing finishing a consumption of paints and varnishes very big. Therefore, the grinding of the ends must be carried out very carefully.

In olden times, a hammer and a blowtorch were used to work the ends. Firing improves the service life of wood, but at the same time the material loses its appeal. Hammer tapped the ends to better connect the fibers together and block the channels through which moisture enters the material. At the same time the surface becomes smooth and firm.

Modern ways of processing wood using various grinding nozzles allow you to perform all the work at the highest level with a minimum waste of time and effort. For grinding the ends, the nozzle No. 160 is first used with a gradual decrease in the grain size to No. 10. If the technological sequence of work is observed, the ends will not absorb much moisture and paintwork, which will increase the service life of the log house.

Recommendations for handling the timber with your own hands

- Too much rotation of the grinding wheel creates deep marks on the surface of the log.

- Processing of wood with residues of resin leads to its smearing, which greatly complicates the process of its removal, therefore, the resin from the surface of the log house must be removed before grinding.

- If the frame in some areas has defects in the form of radial wood, then they should be treated with glue before sanding and allowed to dry.

- Water-based paints and varnishes can, after the first dyeing, raise a nap on the surface of the wood. If this happens, you need to re-grinding.

- It is recommended to grind round logs before mounting doors and windows in the house.

Grinding a log house allows you to increase the performance of a building material, improve its appearance and increase its service life. With such work it is quite possible to cope on your own, but it will take you a lot of time.

Didn't find the answer in the article? More information on the topic:

-

How to handle a tree in the bath?

What is the way to process a tree in a bathhouse so that it lasts longer, and it is comfortable and pleasant to be in it? We will try to consider the main features and nuances.

-

How to caulk a blockhouse?

Instructions on how to caulk a log house with your own hands. Practical recommendations necessary for work tools. Caulk of different materials. Useful tips.