Wood is the most valuable material that is actively used in construction. The popularity of this natural foundation is associated with many of its virtues. Among them stand out:

The tree is rather quickly exposed to moisture and under its influence begins to rot, therefore it is necessary to process the wood with protective moisture-resistant means.

- ease of finishing;

- strength;

- durability;

- absolute harmlessness;

- attractive external indicators;

- ease of installation.

However, despite the large number of positive characteristics, wood is very capricious and may change under the influence of adverse external indicators. In order for this material to enjoy its beauty and practicality for many years, a number of measures should be taken to protect it. How to treat wood from moisture? For this, a number of important nuances should be studied that will prevent the destruction of the rock. About them will be discussed below.

It is worth noting that the strongest tree that can actively resist the process of decay are coniferous samples. There are a number of reasons that affect the ability of trees to withstand the effects of moisture and the development of putrefactive processes on them. This is the degree of moisture of the selected material, its density and the presence of various defects.

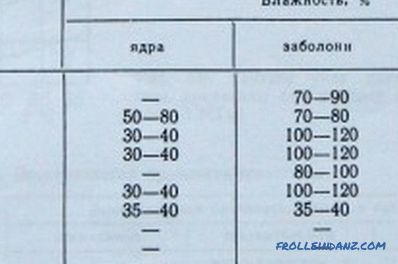

Table of humidity of freshly cut wood.

Speaking of the moisture content of a tree, they share a free and related variety. The first option is characterized by a high rate of evaporation of water from the rock surface. The second type is associated with a similar process, the course of which is noticeably slowing down; it may take several years. Using a special method of drying significantly speeds up this process.

An excess of bound moisture affects the strength of the wood. With its increase it is possible to speak of a decrease in the strength of a tree. At the time of drying the base, first moisture comes out of the surface layer, and a little later - from the middle part of the log. As a result, tension arises from the inside. However, rotting and cracked wood is not suitable for construction work.

Speaking of trees, one should make a difference in them in hardness and softness. The following division was adopted:

- rocks with a soft base (spruce, fir, aspen, linden, alder, cedar);

- hard rocks (elm, birch, maple, larch, elm, apple tree;

- especially hard materials (cornel, hornbeam, boxwood).

For what reason does wood rot?

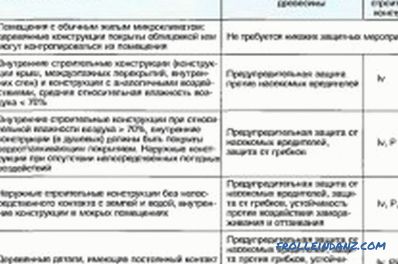

Table of application and effectiveness of wood preservatives.

A tree can be exposed to such influences as temperature fluctuations, dampness, hot weather, and intense winds. Under the influence of such adverse effects, any tree species will not be able to withstand their destructive effects. On their surface you can see mold, fungus, followed by destruction of the rock. Therefore, the processing of wood is required. Now we should talk about the factors that result in such phenomena.

Do all parts of any building experience the same impact? For the most part, those elements will be those that most often come into contact with the environment. These are mainly ground floor rooms, cellars, and window structures. However, it is not necessary to think that other parts of the building from the inside cannot collapse. They are also at risk.

The problem of rotting surfaces has always existed. In ancient times, this problem was solved by harvesting a tree in the fall and drying it before the onset of a warm period. Modern methods of drying the surface are based on more diverse methods of exposure. What tools help a tree to overcome negative external influences?

Design features of protecting wood from moisture

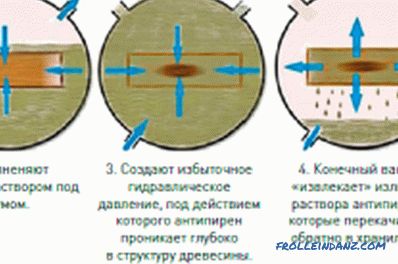

Wood impregnation scheme.

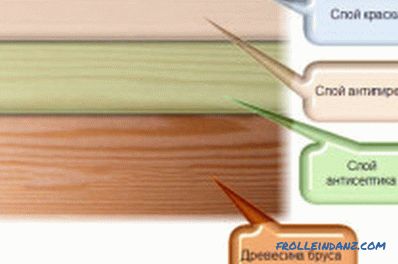

A good oil paint protects you well against moisture. The best means will be various antiseptic compositions and dyes of the porous base. The most common methods of the constructive plan include:

- separating the bases of wood from contact with soil, concrete, stone, metal;

- protection from the weather;

- arrangement building ventilation systems.

It is good if the devices of the carrying plan are open, well ventilated, and provide open access for inspection. An indispensable requirement will be the arrangement of waterproofing wood, not allowing contact with the soil, metal, stone.

One of the most adverse effects on wood is condensate. We must try to avoid such consequences. For this reason, this material is not recommended to be located in those places where there are periodic changes in temperature indicators.The best environment for him will be a room with active heating or location from the outside. Wooden fencing should be equipped with additional ventilation, as well as hinged structures in the form of a cornice or peaks of small size. They provide protection from precipitation.

However, all these measures are few. In order to completely prevent rotting of the base, additional treatment developed in the complex is needed. It is very important to use different formulations of antiseptics.

Antiseptic treatment

The application of antiseptics on the wood surface creates a reliable coating that protects against rotting.

Modern industry has a large variety of solutions presented to help make the right wood coating. As a result, the tree will be reliably protected, it will become a strong and monolithic base, bearing positive fruits for a considerable period of time.

How to choose the antiseptic? To do this, the following aspects should be taken into account:

- toxicity level concerning interaction with fungi;

- foundation resistance;

- ability to go deeper into the tree plane;

- whether it smells;

- harmlessness affecting people and animals;

- inability to change the quality indicators of wood;

- presence in the composition of substances that prevent corrosion.

As for the necessary tools, the following are usually used for processing:

- brushes;

- roller;

- empty containers;

- spray;

- ordinary sponges and others (for example, the same whisk).

Types of antiseptic solutions

Wood preservatives can be of the following categories:

- oil;

- water soluble;

- organic soluble;

- pasty.

The optimal tree protection scheme.

Water-soluble compounds protect the source from moisture and leaching. These include:

- Sodium fluoride. This is a white, odorless substance. Its characteristics are associated with excellent performance. It easily enters the cavity of the wood, but is washed away in a short time. It has no effect on the strength of the base, does not cause its distortion. For the course of treatment of any structure used a mixture of 4%.

- Sodium silicofluoride. It has a similar consistency, but contains slight differences in color, a grayish tint is present here. A substance of similar purpose gives excellent results when combined with the previously considered mixture and soda ash. It has the same characteristics as the previous version. It contains no toxic substances.

- Ammonium silicofluoride is a white odorless substance. In practice, a solution of 5-10% is used. He is able to leach very easily. This substance does not affect the surface of the wood. They are treated with any surface of natural breeds. After such actions, the base becomes incredibly resistant to burning, which is very important.

- The composition of BBK-3 is a substance consisting of boric acid and borax. It dissolves well and does not have a harmful effect on living organisms.

Additional antiseptics

Agents with an organo-soluble value are represented by formulations made from petroleum products such as pentachlorophenol. They actively and deeply pass into the wood. However, such treatment is associated with sufficient risk of intoxication.

The preparation NML is a solvent obtained from oil extracts, copper naphthenate.

It is very toxic. The degree of penetration into the plane of the tree species is quite high. A minor flaw is the purchase of a green shade. Such processing leads to the fact that the wood is not glued. To dissolve is taken kerosene, fuel oil or other substance.

The presence of antiseptic oil substances is represented by various options: shale, coal oil, anthracene oil. These solutions perfectly disinfect the surface, but they smell strongly and unpleasantly. It turns out the color of dark shades of brown tones, a high degree of resistance to washing out with water, the inability to undergo distortion. These solutions are used for finishing sleepers, piles, parts of bridge structures, as well as various devices located under water.

Didn't find the answer in the article? More information on the topic:

-

How to dry a tree qualitatively?

Recommendations on how to dry the tree yourself. Rules for proper drying of wood. Drying under atmospheric conditions. Advice of experts on drying wood.