The level of performance of such a responsible and efficient device as a chainsaw is greatly influenced by the care and timely maintenance of all equipment nodes. A well-prepared chain of quality allows consumers to perform work with maximum comfort and safety. Qualified specialists note that knowing how to sharpen a chain of a chainsaw can significantly increase its service life, significantly increase the return on equipment and its performance.

Features of service

Structure of the cutting element

Structure of the cutting element

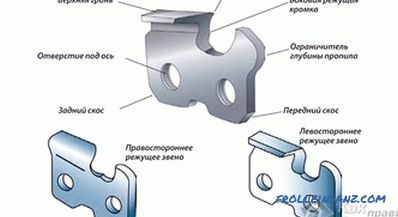

The tooth of the chainsaw has a complex shape from two edges: beveled at an angle top and side. This structure of the tooth requires caution and care in the work. Signs signaling the need to sharpen the chain:

- the saw begins to move from side to side;

- speed and efficiency decreases;

- the appearance and configuration of the chip changes.

There are no defined terms and modes of mandatory maintenance of chainsaws. It all depends on the intensity of the use of technology and its original functional characteristics. Having previously studied the basic conditions and rules of work, in principle, any person will be able to perform such actions as soon as possible. It is necessary not only to learn how to sharpen the chain, but also to prepare special devices, the choice of which depends on the priority technology and the type of equipment.

Use of the file

Sharpen a chainsaw with a file

Sharpen a chainsaw with a file

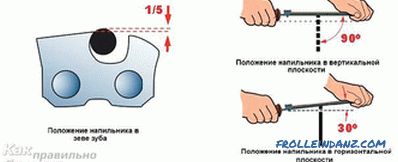

Have any home owner in a box A tool file is stored for sharpening. The main thing is to choose the right file sizes, which are directly dependent on the characteristics of the chain. For example, for 1.3 mm a file is used with a cross section of 4 mm in diameter. To remove the "limiters" at the teeth using a flat file.

The cutting tooth is processed at a certain angle. You need to know that the tooth in the chain link is the original notch of the manufacturer, indicating the recommended angle of sharpening. In addition to the cutting tooth, there is a limiter in the link regulating the maximum occurrence of teeth in the wood. Limiters sharpen not so often, only when real need.

Set for sharpening chains of chainsaws

Set for sharpening chains of chainsaws

For convenience and safety of work, a special auxiliary tool is used the fixture is a clamp with which the saw bar is fixed. In addition, another equipment is used - a template, which is equipped with convenient rollers for movement. It is important to choose the optimum sharpening angle and fix it with the help of a piece. Thanks to the template, the work is facilitated and the risk of incorrect movements is reduced.

The file should be moved in the same direction, not back and forth. Each tooth must have the same number of movements, so that the grinding of surfaces takes place as evenly as possible.

This method is one of the easiest and cheapest, but it takes a lot of time and effort from consumers.

Sharpening with a machine

Chain sharpener

Chain sharpener

Using a file not all chains can be sharpened. The most effective and productive way is the use of a special machine: manual or electric. This is the most accurate technology that can be performed in two ways:

- sequential with a change in polarity;

- the second cutter method, when left-sided and then right-sided cutters are processed without changing the polarity.

When performing work on the machine, several rules should be observed:

- the main guideline of the sharpening level is the dumbest tooth;

- too deep grinding reduces the service life of the chainsaw and reduces the strength of the link;

- experts recommend that after carrying out the work, purge the circuit with compressed air and put it in special oil for two hours.

This method has practically no drawbacks, except for significant time costs and high labor intensity.

Automated sharpening

Chainsaw machine

Chainsaw machine

Sharpening chainsaw chains in automatic mode made on special machines, which are a structure with built-in grinding stone. In the "box" insert the saw, fix it and close. Then it remains only to turn on the equipment at maximum power. The chain revolving begins to sharpen about the grindstone independently, in automatic mode.

Tool for sharpening chainsaws

Tool for sharpening chainsaws

Using a special machine allows you to work on sharpening the chainsaw chain quickly and efficiently , without physical effort and certain special skills. It is elementary and simple. The process of servicing equipment takes only a few minutes.

Knowing how to sharpen a chain of chainsaws, you can save significant funds on paying for services and transportation costs.

Video