Often a large number of consumers choose natural wood species as floor coverings. No one will argue with the benefits of this valuable natural material. Installation of ordinary wooden floor is distinguished by elementary actions. The tree is beautiful in its own way, it is easily processed, has an incredibly strong and stable base, which will please for many years.

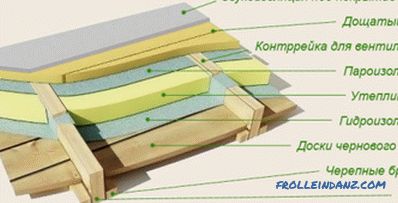

Wood floor installation scheme.

It is quite possible to install the wooden floor with your own hands. It includes laying out boards on a rough base, installing a log with a plywood layer, laying laminate or parquet.

The tree will decorate and complement the look of any room. It is aesthetically appealing, able to provide the highest quality protection against extraneous noise and keep the home warm. Such a base can be updated regularly, covering with a layer of varnish or enamel.

Choosing the right wood

Before you begin the process of laying boards, it is very important to choose the right material. What will be the main thing with such a selection and what features should be paid attention to?

The surface of the wooden floor should not contain various flaws, chips, knots.

- A tree should have a well-dried base, since the board, devoid of such qualities, is capable of deforming after a short period of time.

- The surface of a wooden floor should not contain various kinds of flaws, chips, knots of large size.

- In the process of purchasing boards, it is important to remember the necessary reserve. Approximately 15% is used for cutting material.

- Edged and grooved planes do not require sanding the base.

- Wood of any species must be treated with antiseptic compounds and flame retardants. Such activities will protect the material from the active effects of insect pests and minimize the ability to ignite the base. It is very good if the base of this material is subjected to finishing with preparations that prevent the appearance of rot.

Do not forget about the characteristics of some breeds. So, for installation of a covering in premises it will be necessary a pine, a fir-tree, a larch, a cedar, a fir. These rocks are distinguished by their foundation strength, increased resistance to mechanical stress and an affordable price.

Structure of wooden floors.

Installation of high-quality wooden floor in bedrooms and rooms for children involves the use of alder, oak, aspen. Their cost is low. Do not forget about the features of the climate of the selected area, the premises, the permissible level of loads, regular use, the possibilities of the material plan.

The essential point will be a clear selection of the type of coating from natural rocks, the basis on which it will be laid. Thus, birch, pine, ash, walnut, and red oak are well suited to cover wood with a thickness of 19 cm and a thorn-comb locking device. The presented species of rocks are characterized by a special strength and rigidity.

Particularly interesting and original will be the parquet, made in the piece version, laminate flooring and parquet. The basis of this kind is very nice, it is strong and resistant, not afraid of significant loads. The flooring of the wooden floor can be carried out on the concrete pavement, logs and on the draft basis of beams of natural wood. In order not to be mistaken in the choice, it is worthwhile to focus your attention on impregnations, in this case tung oil will be optimal. It creates a protective layer that provides the foundation with hardness.

The rules for laying the floor on the logs

The flooring with natural wood is carried out in the following ways:

Laying the floor log.

- On concrete or reinforced concrete slabs, which is typical of brick buildings and panels.

- On beams of steel and wood, which are observed in houses of natural breeds and on the frame.

- To special support posts made of brick, concrete, wood. This feature is typical for cottages.

Most often, the installation relates to structures on logs, they are mounted on the ground or on the floor. The result is a coating with a special strength, with remarkable performance to keep the heat and absorb extraneous sounds. The covering gets ideal indicators. Parquet, laminate, tile, carpet and other materials for the floor are laid on such a coating.

Lagging allows you to hide various communications, engineering networks, flaws and other irregularities of the coating under the base of the floor. However, this design is unacceptable for rooms with low ceilings. In the process of activity, 7-10 cm height will be cut. For such an option, flooring with wooden planks would be suitable, under them a waterproofing layer is fixed.

For the installation of the structure on the logs, initially a base should be prepared.It is thoroughly cleaned from litter, cracks and grooves are smeared. Now a waterproofing membrane, polyethylene film or penofol is laid on the floor. This should be done with an overlap of 20 cm. Such measures will save the foundation from moisture.

Required tools

- hammer;

- lacing;

- level;

- screwdriver;

- hacksaw .

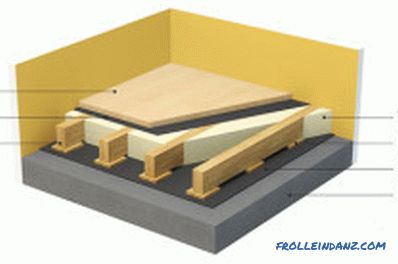

Scheme of the base on logs.

The installation of the lag begins with the preliminary work, namely, from the moment of their adaptation. It occurs by putting this base into the room for several days.

It is necessary to lay logs in a position opposite to the light of the sun. In order to get the base to perfectly smooth indicators, you can use a water level or a thread from nylon.

The height of wooden floors can be checked with wedges made of wood. They are laid on both sides. In addition, sometimes used refined sheets of plywood, divided into components, each of which is equal to 15 cm. Wedges and logs are reinforced with screws or nails of a certain length, attached to concrete with anchors or dowels.

The installation process is carried out by fixing 2 lag at the walls from opposite sides. In the space between them, a kapron thread is pulled. The following parts are installed on it.

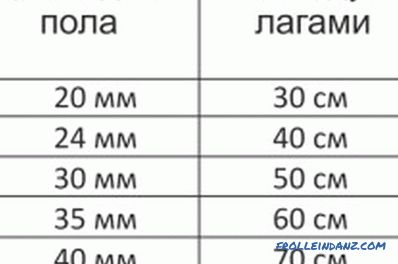

The distance between the floor logs depending on the thickness of the floor board.

The gap between the lags is often filled with any insulating material. It will be mineral wool, which does not leave a single gap and voids. As a result of this installation of wooden floors, the base acquires the properties of high-quality insulation from the side of maintaining heat and absorbing sound waves. As a result, you can get the most convenient and comfortable coating.

As soon as the preparatory work is completed, you can begin the flooring of chipboard or plywood with a moisture resistant base. For fasteners taken nails, whose heads are hidden.

In order not to be mistaken with the dimensions of the boards, it is necessary to consider fixing the topcoat. Joints should be located in the middle of the lag. Installation of the first row is done by retreat from the wall by 1.5 cm. We should not forget about the leveling measures. As such a sample, you can take a nylon thread. Board from the edge is mounted at an angle. Screws need to be screwed into a pre-drilled hole, then they are screwed under the cap.

At the points of passage of the pipes it is necessary to make holes whose diameter is larger than the base of the pipe. Brackets are used as additional fastening elements.

You can lay regular plywood, which will give the floor the perfect quality of the rough coating. To carry out further installation on such a basis is not difficult. As a result, the plane is perfectly flat.

Floor leveling scheme using lag and plywood.

Such work is not carried out in rooms with a high degree of moisture. In this case, the floor will quickly become unusable due to constant deformations.

The absence of such conditions will give grounds for further work related to the flooring of a wooden floor. To do this, garbage is removed from the base and markup is made with chalk. The plywood is placed on the floor and the attachment points are fixed. Lighthouses are defined on the floor, delimiting the base into equal squares with an edge of 20-30 cm. Screws are screwed in the corner points and the lag is laid.

When performing the listed work, it is important to monitor the evenness of the bars. There should be no sagging. They are fixed with anchors, the caps of which are recessed. The whole structure must be glued with a special compound. Plywood is screwed with screws.

Features of wood flooring

Any coverage will last longer if you properly care for it and regularly update it. When doing the cleaning, it is important to use a brush with soft and long bristles.

Avoid spilling liquid onto the floor.

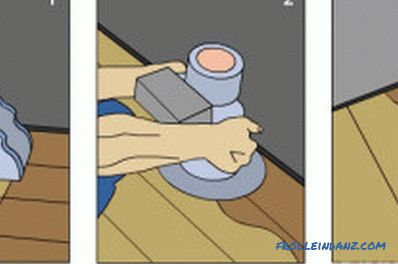

Wood floor scraping scheme.

If any marks appear, immediately wipe the base. Wood as a material of natural species is afraid of mechanical effects, for this reason they should be reduced as much as possible. You can not walk on this floor in heels. Rubber pads should be worn on furniture legs. As a means you need to use special solutions for wooden surfaces.

A reinforcing mesh is used for waterproofing. It is made on the basis of fiberglass, their dimensions correspond to 4 * 4 mm. Such a device is suitable for cracked surfaces and those experiencing maximum loads. The grid is installed between the layers of waterproofing. In this work should be carried out in a short time that will not allow pre-solidification of the mixture.

Shortcomings will be the high cost of construction.The advantages are the excellent quality of the insulation, the flexibility of the material and the high speed of the installation work. Facing plates or other materials can be mounted in the upper part of such a layer.

All the listed tips and recommendations will help to carry out the installation of a wooden floor on their own, without the help of experts.