Arrangement of the yard or suburban area implies the creation of a certain level of comfort. For example, it may be the presence in the pool, a small garden, a shed with barbecue or gazebo. As for the latter, there are many building materials and technologies for the manufacture of gazebos. In the article we will tell you how to make a polycarbonate gazebo with your own hands, consider the options using metal and profile, demonstrate the drawings, photos and video instructions for building a simple gazebo to give.

Advantages of construction and material

A polycarbonate structure has several advantages, among which:

- The relatively small weight of the structure. Given the light weight of polycarbonate, under such an arbor is not always required to fill the foundation. Such a structure can be easily dismantled or moved to another convenient place.

- Simplicity in manufacturing. You can buy such an arbor already finished, but it is quite realistic to make it yourself.

- Accessibility of materials used. The construction of the gazebo does not have in itself rare building materials that are difficult to obtain in our country. At cost, it can be cheaper than gazebos made of brick, wood, and especially forging.

- Ability to combine. Such material as polycarbonate is perfectly combined with a large amount of materials.

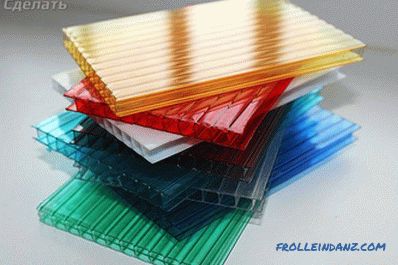

Polycarbonate

Polycarbonate

So, by itself, polycarbonate has a large number of positive sides. Due to this, such material can become almost indispensable in the manufacture of arbors. Below are the positive sides of polycarbonate:

- flexibility both across and along;

- easy to drill;

- easy to cut;

- non-combustible;

- has sufficient strength;

- the service life is 20 years;

- it can be used in a humid climate;

- it is not afraid of temperature drops;

- it is distinguished by good translucent ability;

- resistant to ultraviolet rays.

As can be seen, the construction itself and the material used have a large number of positive sides. All this can overcome doubts and fears when choosing the best option.

On what to stop the choice

Having decided to use polycarbonate for the construction of an arbor, you should think about many other issues. We suggest that you familiarize yourself with those nuances that should be considered when creating drawings and a project, respectively.

The type of arbors are:

- Open. This design will allow you to feel in harmony with nature. For its manufacture, you can install a metal frame.

- Closed. This structure will be reliable protection from the weather.

Closed gazebo made of polycarbonate

Closed gazebo made of polycarbonate

By the way setting :

- Portable. It is very convenient if you like to change something from time to time at your summer cottage. The simple and lightweight design will allow you to rearrange to another convenient place.

- Stationary. In this case, a gazebo is built, implying the arrangement of a reliable foundation.

By the complexity of the construction :

- Normal canopy. To implement this design does not require a lot of materials and effort. A canopy is built on several pillars of supports.

- Complicated structure. In this case, a gazebo can have an intricate shape, which will be a great addition to landscape design.

By the equipment :

- Simple arbor. Intends for gatherings in the bosom of the family.

- With a brazier. Allows you to spend a pleasant chat for the adoption of delicious food cooked on fire. In this case, you should not retire from the guests, and spend all the time together.

By functionality :

- Carrying the functional load. This gazebo will protect others from the sun, rain, and also serve as a great place to spend your holidays.

- Decorative element. The arbor can be made of different materials, and also of polycarbonate of different colors.

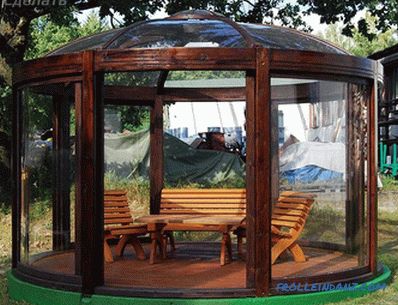

Round gazebo made of polycarbonate

Round gazebo made of polycarbonate

By form:

- Round.

- Square.

- Rectangular.

- Hexagonal.

- Octagonal.

- Modular.

Project works

Now it is worth solving some details concerning the arrangement of a summerhouse on the summer cottage. And the chosen place will play an important role. It is necessary to take into account such details:

- wind rose;

- near growing trees and bushes and the level of shadow from them;

- the presence of uneven ground;

- whether there is a slope or mostly plain.

Regardless of the location chosen, it is important to carry out all the preparatory work for its cleaning and preparation.To do this, also think about this:

- what will be the total weight of the structure;

- what level of complexity;

- the size of the building.

It is important to think through all these details in advance, because it will be influenced by the choice of a specific material for the manufacture of the frame.

Selection of material for the base

You can use different materials for the manufacture of the frame. For example, it could be:

- Tree. This material is available, environmentally friendly, has aesthetic properties, but quite demanding in the care.

- Metal corner or profile. Here, of course, dignity in strength and long-term operation. But for the arrangement will require the skills of the welder. Plus, a fairly high cost.

In this article we will consider the sequence of manufacturing arbors, using different building materials for the arrangement of the frame.

Wood

For the construction of a tree arbor with a combination of polycarbonate, you can build a columnar foundation. For the construction of the foundation, it will be necessary to perform work in the following sequence:

- First of all, make the markup according to the project.

- Dig holes up to 700 mm deep in the designated area.

- The bottom of the pit should be filled with sand and rubble, a common layer of 50 mm.

- Now you need to prepare concrete for pouring the foundation.

- Install wooden supports in the recesses. Pre-treat them with a special compound to protect against corrosion. Also part of the support, which will be in the concrete, can be wrapped with roofing felt, which will increase the waterproofing properties of the arbor base.

- Each rack must be set strictly to the level.

- After concreting, install temporary support on each rack, for example, securing the timber diagonally and resting them in the ground. This will allow in the process of hardening of concrete not to move the supports to the side.

In the process of solidification of the foundation, it can be watered from time to time with water. But do not pour the foundation, just wet it slightly. This is especially true during hot weather.

After the base has dried, you can proceed to the construction of the frame.

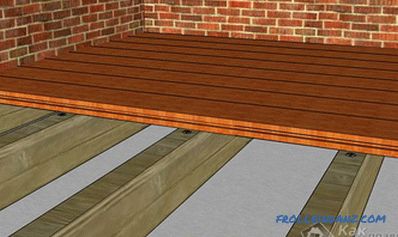

Floor frame

- To get a strong floor frame, set logs every 400 mm. For the frame, you can use a timber section of 50 * 150 mm.

- The lag should be set strictly on the horizontal level.

- If the arbor design should have additional support drains for the roof, they should also be installed.

- The edging board can be used for the construction of the flooring. It should also be treated with an anti-corrosion compound.

- Boards are fastened to the floor with screws.

Roofing and wall finishing

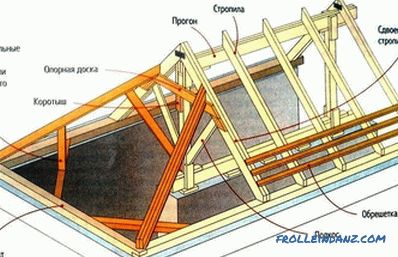

At this stage it is worth deciding what type of roof will be installed. For example, it can be single slope, gable or hip. We consider an example of the manufacture of a simple design - single-sided.

- To begin with, it is necessary to install the top trim of a timber with a section of 100 * 100 mm.

- At the end of each support, make L-shaped cuts. In these grooves set strapping bar that connects all the racks.

- The binding bar is fastened with nails that need to be driven in at an angle or with self-tapping screws. To prevent splitting, you can pre-drill a hole.

- Next, you should make the bearing rafters and crate.

- In conclusion, it remains to fix the polycarbonate.

Upon completion of the construction of the roof, it is necessary to paint the entire structure or varnish it. It all depends on your choice.

Arbor from wood and polycarbonate

Arbor from wood and polycarbonate

As for the manufacture of walls, it all depends on the type of construction. If it is an open arbor, then it will be enough to build a railing and later install benches. If closed, the need for the manufacture of the frame will depend on the size of the gazebo. If the gazebo is small, it is enough to fix the polycarbonate to the uprights of the building supports. But for reliability it is better to install additional supports.

When attaching the cellular polycarbonate, install the sheets vertically. It will not provoke the accumulation of moisture inside the sheet.

Interior and exterior design

At this stage you can assemble individual elements inside the arbor. For example, a table, chairs, benches, bar counter and so on. In the manufacture of furniture, it is important to use high-quality material, since such gazebos are not heated. As a result, at low temperatures, poor-quality material will quickly become unusable. So every season will have to engage in the manufacture of new furniture for the gazebo. Consider whether the backrest will have benches or chairs. It also affects the usability of the facility.

Exterior works on the arrangement of the exterior play an important role in creating a comfortable resting place in the summer cottage. This includes a whole range of works:

- Facade decoration. This is especially true if you have an open gazebo. Wooden elements are painted or lacquered. You can also use the decor.

- Arrangement of a garden path to the gazebo.

- The construction of the club around the perimeter.

- Installation of lighting.

According to this scheme, it is possible to build a polycarbonate gazebo on a wooden frame.

Of metal

Such a structure will have a sufficiently high strength. For manufacturing, you can use metal corners and pipes. To put it in a nutshell, the process of building such an arbor is as follows:

- Installation of supports.

- Bottom trim and flooring.

- Making fencing and roofing.

- Fastening polycarbonate.

The principle of work for the manufacture of arbors of metal and polycarbonate is similar to the method of manufacturing structures made of wood. We will discuss some of the subtleties when working with metal.

Required material and tool

Required tool and material

Required tool and material

If the project is ready then take care of the following:

- For supports steel pipes Ø50 mm.

- For the manufacture of rafters, fencing and strapping metal corner 40 * 40 mm.

- Mounts, metal screws.

- Material for flooring, for example, it can be wooden flooring or a concrete screed.

- Polycarbonate and accessories for its installation.

- Sealant.

As for the tool, prepare:

- welding machine;

- hacksaw;

- ground drill;

- screwdriver;

- jigsaw;

- pliers;

- hammer;

- level;

- saw for cutting polycarbonate.

If you do not have the skills of a welder, you can rent a welding machine for a day or two and hire a professional welder.

Installation of the supports and the base of the floor

The first step is the marking, after which the installation locations of the supports will be determined. After that, work in the following sequence:

- Using a drill, drill holes in the ground. Depth is from 700 to 1000 mm. The diameter of the pit to 100 mm.

- The bottom is filled with sand and rubble, a layer up to 200 mm.

- In the pit, lower the pipes and level them. Before making concreting, it is necessary to make a support struts. For this you can use a wooden beam.

- Work should continue after the concrete has dried.

- In the next step, the bottom strapping is performed. Weld the corners to the pipe supports. On top of them lay logs and wooden flooring.

- To fix the wooden logs, make holes in the corner and bolt.

- As an option, you can make a screed and lay the floor in the gazebo with tiles.

The brazier can be installed in the metal arbor. For this, the selected area is sheathed with refractory material. A concrete screed with a thickness of at least 400 mm is poured into the base.

As an option, you can use the budget option by filling the floor with pebbles or sand. But for this purpose, it is necessary to install a side around the perimeter of the arbor, up to 150 mm high.

Forming a frame

- To fasten fences, weld transverse supports to the uprights.

- After that, the top trim must be welded. It should be durable, as it will fit the roof.

- Rafters and other elements of the ceiling can be welded on the ground on a flat surface. When everything is ready, it will remain to raise the frame of the roof to the top and finally weld it to the pillars of the support.

When the frame of the walls and roof is ready, it must be painted. It is recommended to use anti-corrosion compounds that prevent rust.

Cladding

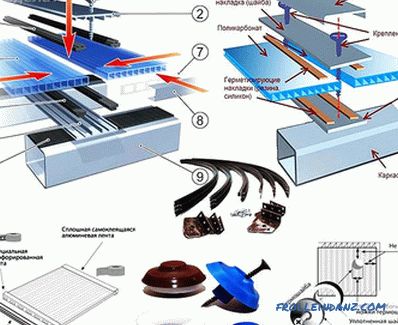

Finally, it remains to make the fastener of polycarbonate. For this, the sheets of material must first be cut to the required dimensions. At this stage, you should decide what to cover the roof. You can use the same polycarbonate, and you can build a roof of another material, for example, decking or slate.

For fastening polycarbonate, make holes in the metal corner in advance. After using special self-tapping screws with heat washers, fasten the sheets. At the same time, check that the screws do not hold the polycarbonate tightly. As for the material docking, it is better to use special plastic profiles for this. To achieve tightness, process the joints with silicone or other similar sealant.

From the profile

This option for making a gazebo is similar to the process of mounting a metal structure.Only in this case, the basis of the frame is completely made of profile and polycarbonate. Therefore, for the construction of gazebos should buy a profile pipe, square or rectangular cross-section. For the arbor is best to use a square profile. For the arrangement of the arbor, you can use both aluminum and metal profiles. The profile is more resistant to stresses and stronger.

To perform the work, you need the following tool:

- hacksaw;

- Bulgarian;

- welding machine;

- electric drill .

Foundation

Aluminum profile is a relatively light material. Polycarbonate is also lightweight. From here it becomes clear that you should not build a heavy-duty foundation. You can make shallow deeper ribbon foundation.

- For its production, you should dig a trench to a depth of 300 mm along the perimeter of the future arbor.

- The bottom of the trench should be covered with rubble.

- You also need to make a reinforced belt of rods.

- Having built a formwork, you fill it with concrete.

It is very important to lay metal parts in concrete. An aluminum profile will then be attached to them, for the manufacture of a frame.

If you plan to build a large arbor, then, of course, make the foundation more powerful by digging up to a depth of 700 mm.

Assembling the base and frame

An important part of the arbor of the profile is the base. Therefore, everything should be done exactly according to the drawings. So, the details are cut into the necessary segments. It is also necessary to prepare supports for which the roof will be mounted. Alternatively, they can be concreted or attached to embedded parts. The last option is not very reliable.

Fastening the roof

Fastening the roof

The entire frame can be assembled by means of a bolted connection. But this design will be less durable. Another thing if you use a metal profile. Then all the connections can simply be welded together. For the construction of the roof, as in all other cases, you can lay polycarbonate. The main thing is to carry out its correct installation.

For the sake of objectivity, an arbor made of aluminum is not as reliable as of metal. Plus, the material itself in the cost is quite expensive.

Polycarbonate flooring

Polycarbonate flooring

So, we learned with you how to make a gazebo from polycarbonate using different materials for its base. Below we suggest you to familiarize yourself with the drawings of the arbor.

Video

In the provided video, it is shown how to make a polycarbonate gazebo:

Photo

Below you can see a number of photos, in which the arbor from polycarbonate in different execution is represented:

Arbor from metal and polycarbonate

Arbor from metal and polycarbonate

Polycarbonate gazebo at the cottage

Polycarbonate gazebo at the cottage

Gazebo with the brazier

Gazebo with the brazier

Of polycarbonate with paving

Of polycarbonate with paving

Cascade with polycarbonate

Cascade with polycarbonate

Frame for the gazebo

Frame for the gazebo

Round shape

Round shape

Small arbor

Small arbor

Lighting

Lighting

Portable arbor of polycarbonate

Portable arbor of polycarbonate

Rectangular

Rectangular

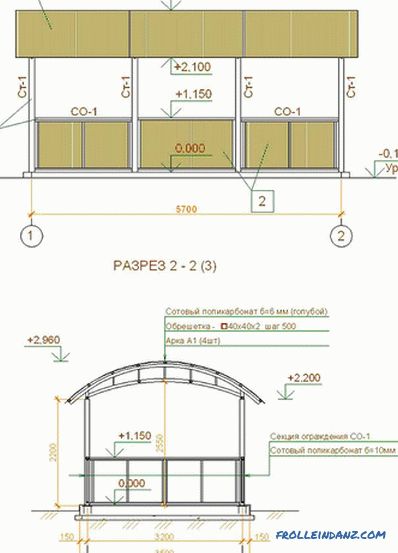

Drawings

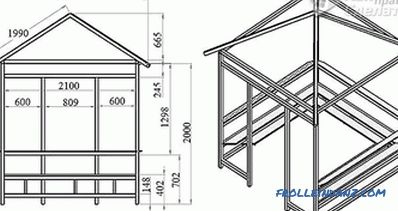

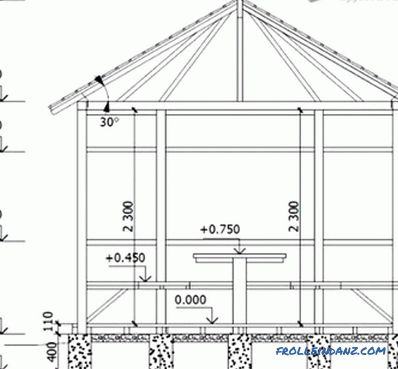

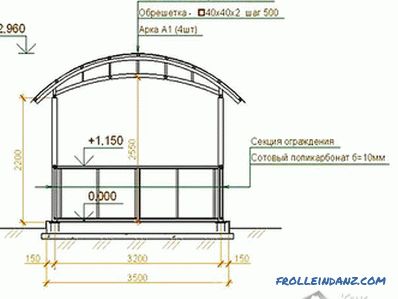

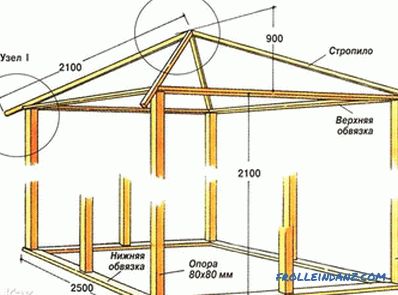

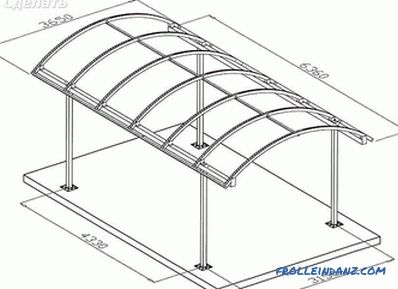

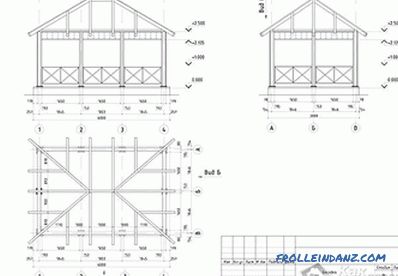

If you decide to make a polycarbonate gazebo on your own, diagrams and drawings will help you with this. :

Drawing of the arbor

Drawing of the arbor

Wooden arbor

Wooden arbor

Metallic

Metallic

Polycarbonate and wood

Polycarbonate and wood

Drawing of a simple canopy for a gazebo

Drawing of a simple canopy for a gazebo

Project of an arbor

Project of an arbor

Poly mounting scheme carbonate

Poly mounting scheme carbonate

Polycarbonate mounting scheme through the split profile

Polycarbonate mounting scheme through the split profile