The miter saw is often called face-cut or simply trimmed, and this tool is in great demand when carrying out many construction works of various sizes. Such a saw is required when you need to cut a tree at a certain angle. Face saw is used in the case of working with aluminum, plastic. How to choose a front saw with regard to the amount of work?

The miter saw is used in many construction works, it is easy to use, works precisely and with great speed.

Typical for this tool are high speed, accuracy of execution of specific operations, ease of execution of work.

As for the field of use of the end-saw, the possibilities are very wide.

First of all, you can use it during carpentry work, as well as during installation, finishing. In the workshops for the production of furniture and repair of wooden products without an end saw is simply not enough.

In addition, you will need this tool, if you need to cut iron, use cast profiles, cut steel. Face saw is used in enterprises where window frames are made from the profile. As you know, in the end saw, the initial load falls directly on the spinning disk, in connection with which it is made of heavy-duty material. Often the face saw is also called an assembly saw, because it can greatly facilitate the actions performed during the installation of any element.

Face saw device

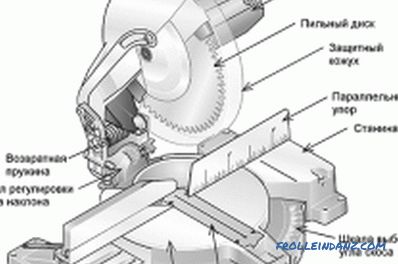

In order not to be mistaken with the choice of tool, you should know something about its design.

Edge saw arrangement.

This is a dusty disk, the engine itself with a gearbox, and the base of the handle that starts the button. On such saws, the engines are different - collector and asynchronous. Using an asynchronous motor produces less noise, and the tool itself lasts longer. The main advantage of this engine can be called the lack of regular maintenance, excessive attention. In relation to the disk, the engine is fixed on the right side, but in some machines it can be at the back to provide a better view and comfort of operation.

The saw blade rotates by means of an engine, through a reducer, it transfers the required type. Each program has its own advantages, there are some drawbacks. So, with a gear drive under high loads, the possibility of slippage is excluded, and with a belt less noise, the disk vibration is eliminated, therefore the service life of the engine is prolonged, the quality of work is improved.

Important tool parameters

By choosing a desktop tool, you can buy a face saw that combines two functions in parallel.

A saw, additionally equipped with a sawing table, is perfect for working at home.

This is a sawing machine and the end-cut saw itself. It should be noted that both of them in practice are trimmed saws, they were simply retrofitted with a sawing table. You need to know that the combined-type end-saw cannot fully replace a specialized machine, but many craftsmen prefer to use just such a tool, because at home it ensures accuracy of work and its speed.

Some such saws have the function of pulling, when the saw blade is installed using two rails, they are arranged in parallel, there is the possibility of free movement. For the face saw with broach, the presence of a significant width of cut on the material being processed is characteristic.

Selection Criteria

In order to select and purchase a face saw correctly, take certain points as a basis.

Options for using the end-saw.

First of all, specify the purpose for the implementation of which the instrument is required. If frequent use of the saw is not required, then you can limit yourself to a tool that has standard functions. But with the upcoming large amount of work of increased complexity, it is better to buy a professional face saw.

Pay attention to safety, as a rule, there is a protective casing, during operation it completely closes the disk. Weight and dimensions are no less important, because an excessively massive tool makes work difficult, and people working with such a saw get tired more quickly. As for the size of the dusty disc, the size of the cutting tool itself should be chosen with a diameter of at least 20 cm.

The main defining characteristics of the end saw should be the cutting depth and its width. This determines exactly what the unit you purchased can process. The diameter of the disk, choose one that is larger. The quality of the swivel block is important, the quality of the bed should be considered a no less important indicator, be sure to consider this when purchasing.

Selection of the saw blade

The choice depends on the material to be processed.

The choice of the disk depends on the saw itself and on the material being processed, the diameter and shape of the teeth affect the quality of work.

The main parameters should be considered as the landing and outer diameters. For a landing disk, this is a 3 cm indicator, while for an external one, the dimensions vary. When choosing a disc, remember that often the engine of an aggregate involves the use of a particular disc. And it so happens that an overly large disc harms the saw. The quality of the final work depends on the sharpening of the teeth of the disk, its geometry, and the material is also important.

Some types of teeth proved to be excellent when processing cross sections, while others work perfectly with the longitudinal, thanks to the third cut, it turns out to be even and fairly clean. Please note that some models of the disk are endowed with wavy lines, they can differ in thin cuts, which ideally compensate for the temperature deformation.

In addition, they are able to reduce the noise arising in the process. Many manufacturers make trunk expansion with basic equipment, but if you have to work with large sizes, then additional supports may be required for the unit.

How to choose face saws is a simple question, the main thing is to determine the exact goal and scope of work.

Didn't find the answer in the article? More information on the topic:

-

How to choose the bits

for the screwdriverBits for the screwdriver: how to choose high-quality nozzles. 3 rules on the choice of bits. The choice of bits depending on the brands: nozzles of types Sl, Pz, Torx. Selection parameters according to generally accepted characteristics.