The originally Russian bath is traditionally made of wood. And this applies not only to interior decoration, interior and bath accessories - the right bath involves the very construction of the log of this material. Accordingly, the builders should be concerned with the question - how to process a tree in a bathhouse so that it lasts longer and is comfortable and pleasant to be in it. Under the term "coating" fall chemical compositions, not only saving the tree from mold, fungus, rotting and insects, coverings that provide fire protection are also important, after all - wood.

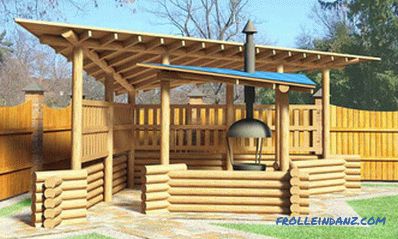

Since ancient times, it is believed that a real Russian bath should be built of wood. For its additional protection logs must be treated with special means.

Before working and choosing the means for surface treatment in a bath, several conditions must be met:

- to select the right wood;

- drain devices and the position of the bath floor affects the coverage;

- the purpose of bathing rooms is the main issue in choosing "chemistry";

- take into account the degree of wear of the bath;

- the choice of special tools and tools for work.

Tree selection: features

It is undesirable to use coniferous sorts of wood for finishing the steam room, as at high temperatures resin is released, which is toxic.

For each room of a wooden bath, a certain type of wood is chosen - deciduous or coniferous. Coniferous boards are able to release resin, which, along with the healing coniferous smell, emit toxic substances that do not contribute to health. It is necessary to remember - coniferous wood in the bath is used in the waiting room or washing room. In rooms associated with high temperatures (steam room and firebox) needles can not be used, only deciduous.

And if such a blunder was made by inexperienced builders, then the question of how to process a tree is urgent. Covering the walls, floor and ceiling in the bath with protective chemistry is absolutely impossible - you can not leave the bath alive. Paints, linseed oil, wood varnishes and mastic with wax are contraindicated. The construction industry produces non-hazardous chemicals for the bath. It is only necessary to look, that it has been marked, as "sauna".

You can use a harmless and environmentally friendly old-fashioned way of processing - the entire wooden coating is rubbed in 2 doses with vegetable oil. Only this should be done with regularity - once every six months. Or another way - than treating wood for steam rooms - to use a blowtorch for firing wood, and then an emery wheel for sanding the surface. This method of processing is dangerous to fire and not durable, but the wood takes on a noble, beautiful look.

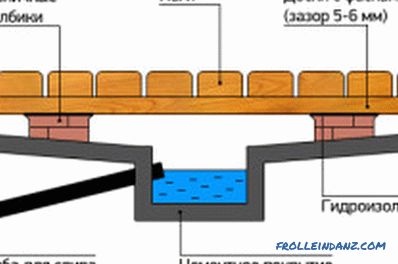

Correct position of the floor and drain - a guarantee of durable wood coating

The floor and drainage scheme in the bath.

Even when expensive quality material is used as a coating treatment, it will not save the tree from mold and mildew if the floor is in constant contact with water. It can be caused only by one reason - the wrong device of the floor and sinks. The installation of the subfloor should be carried out with a certain inclination so that during pouring the concrete could precisely copy the surface and direct the flow of water in the right direction.

Finishing floors in the bath are lined exactly on the level, forming a triangle of space beneath concrete or earth - the water goes off and the wood dries out and all the chemical elements and the coating treatment is again in effect. By the way, floor boards, and all wood in general is covered with an antiseptic from all sides, otherwise there will be no benefit. Washing rooms can be treated by spraying a copper water solution, but they need to be ventilated for a long time - 2 weeks before direct “start-up”.

Appointment of rooms in the bath

The waiting room and washing room can be waxed.

Rooms with elevated temperatures require careful selection of the coating. Heat can not only heal, but also help harmful evaporation, fill the entire steam room or room with a stove. It is best to listen to the advice of experienced builders who do not abuse chemical coatings, and devote more time to the device of ventilation in the bath. Then the tree will always remain dry, and the steam will not mix with chemistry, because of its absence.

The dressing and washing facilities can be treated with a water-based lacquer or wax. Of course, all materials must be certified. The current chemical industry offers water-based paints specifically for treating the bath inside. The surface is beautiful, relatively safe, but extremely expensive. And you should not expect any special natural odors from wood - the colors will completely drown them.

It is better not to process the rooms with a firebox at all or only with a fire-fighting compound.

A pair should not be there, and dry hot air will only benefit the tree. Of course, provided that the construction of the bath was conducted from properly and until the end of the dried material, otherwise the tree will crack.

Degree of wear

When restoring an old bath, it is usually sheathed inside with a clapboard.

It so happens that the old bath is not withdrawn from circulation - it has already shrunk for a long time, has shown its good, and not so much, qualities, has become native. Therefore, the owners want to simply restore it and continue to use it further. Restoration is the lining of the nutra lining and "podshamanivanie" outside.

There is only one minus here - to use covering antiseptic, varnishing and antifungal substances will have to be buckets. For the tree has become porous, it absorbs everything and in huge quantities. The question is how to process the tree of the old bath - without an answer. It makes no sense to cover the old buildings with anything - restoration, renovation and processing is carried out only mechanically - grinding, polishing and rubbing oil.

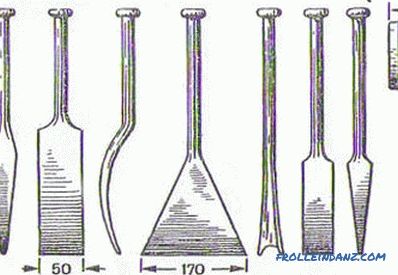

Working clothes and tools for working with a coating

When treating wood with any chemical solution, be sure to wear a respirator.

Overalls should include:

- a respirator or in case of emergency wet gauze dressings that change every hour;

- the suit is desirable, but home masters are not puzzled by this;

- rubber gloves with a grooved side are required;

- safety shoes.

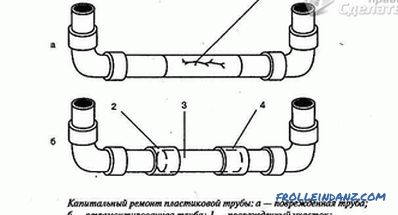

From the tools you will need:

- A container for diluting coatings - varnishes, paints, mastics and drying oils. It is also convenient to use them if a roller is selected as a spreading agent.

- Brushes - wide and narrow, for hard-to-reach places. The hand spray gun will cope well with this problem - the surface will be covered perfectly.

- Pumice stone for mashing the entire surface before coating. Thinner or other neat streamer.

In conclusion, it should be said about the outside of the wooden bath. The technology of coating external to internal is not much different, for example, you can use oil paints or acrylic.

Didn't find the answer in the article? More information on the topic:

-

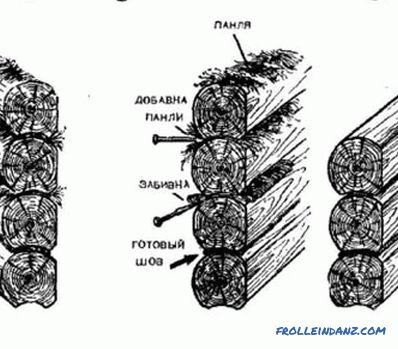

The better to caulk a log house?

Recommendations on how to caulk a log house. Requirements for caulk material. Varieties of caulking material suitable for timber.

-

Tools for caulking a house from a bar

The caulk of the house from a bar protects it from external influences. For caulking iron, felt, moss, jute, hemp and tow are used. Plugging the gaps between the logs can be 2 ways: stretching or in the set.

-

Why do we need wood treatment with wood stain and varnish?

The rules for processing wood stain and varnish. Preparation of wooden surfaces for processing. Brief description of the main types of stains and varnishes for wood. Processing technology and the right tool.