You can build a bath yourself or purchase a ready-made log house and put it on a foundation. The first option takes more time, and the second is dangerous because you can buy low-quality or defective construction. If you choose a finished structure, then keep in mind that in the log cabins it is necessary to seal the gaps between the logs. What is the best way to caulk a log house so that it lasts a long time?

A bath caulk is a seal between the logs.

A bath is a building that is used for washing. There is no constant heating in it, and the stove is heated only when they are going to wash. In this case, with a firebox, the difference between the temperature inside and outside the building is very large, for example, in the bath + 70 degrees Celsius, and outside - 10. It is wet, a lot of water and steam. The materials used for log cutters should meet the following requirements:

- keep heat indoors;

- withstand temperature changes;

- not absorb moisture and steam;

- air through;

- characterized by a long service life.

There are several materials that are well suited for sealing gaps in the walls of the bath: moss, jute or linen, sealant.

In fact, other materials are used for caulks, such as tow and felt, but they are not suitable for rooms with a high degree of humidity.

Materials for cauldrons of the bath

Moss has long been used to fill the gaps between the logs. It is inexpensive, but it is more difficult to work with it than with modern materials. If you decide to close the joints between the logs with moss, first wet it a little, because it is crumbly. Only two types of moss are used: kukushkin flax and sphagnum. The first is wound into tapes, which are inserted into the gaps in several rows. The second one is used in the form of fibers, which hang about 5 cm from the gaps when blocking. Then, using tools, you need to caulk the material deep into the joint.

Types of materials for bath caulks.

Jute and linen cloth - tape insulators, that is, the canvases are cut and folded into small skeins. Their disadvantage is that with time the moisture resistance decreases and the bath will need repair.

The sealing of the joints between the logs is done in two ways:

- "in the tie" - the material is divided into narrow ribbons and inserted into the gaps;

- "in the set" - divided on the thread.

The newest material for filling gaps between bars is wood sealant. It is sold in plastic tubes, in the form of briquettes or cords. This is the only not natural, but synthetic material. It has a high degree of resistance to temperature extremes. To fill their joints, rather a special construction pistol. The mass is simply squeezed into the gaps and fills them. Sealants come in different colors, you can choose a shade to match the color of the bath itself.

Procedure for a log caulk

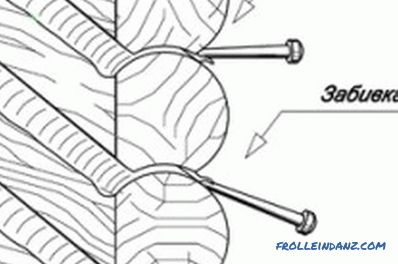

Scheme of a log caulker.

A log house must be caulked twice: immediately after installation and after it has shrunk. After a few years you need to check the condition of the gaps between the bars. It is possible that in some places it will be necessary to replace the insulation.

When using any material, several flat-tip wooden blades and a hammer will be needed to seal the gaps. The material is inserted into the gaps between the bars with a spatula, and you need to knock it with a hammer on it so that it penetrates deep into. But you do not need to knock very hard, and then the gap will simply become larger.

After installing the log house on the foundation, you need to start closing the gaps. Next, you should prepare the necessary tools, pick up the material, make the calculation of the desired quantity. You will need to calculate the perimeter of the building, multiply it by the number of joints between the bars and subtract the width of the window and door. Remember that you need to caulk not only from the street, but also from inside the room, which means that the resulting number must be increased by 2 times.

The log of a log frame with any material starts from the bottom of the joint. It is necessary to seal the lowest gap on all walls around the perimeter of the building, first outside, and then from the inside. Next, we close the gaps between the second and third walls of the walls, etc. This is due to the fact that the height of the wall increases with the caulk. If you do the work unevenly, then the whole log house will distort.

Didn't find the answer in the article? More information on the topic:

-

Waxing

What is the impregnation of waxed wood and its types. Technology waxing process with a detailed list of necessary materials and tools. Features of wood processing various types of wax.

-

How to properly caulk a house from a log

Before you caulk a house from a log, you must decide on the material with which you make the insulation. Moss, tow, lnovatin, jute fiber, jute are used.