The door slopes can be trimmed both under a straight line and at any other angle; it can be external and external. External is made from moisture resistant and cold-resistant materials.

For plaster of an external slope it is worth applying special solutions intended for such type of finishing. Currently, the construction market has a very large selection of materials for such works.

Selection of materials

Preparation of plaster

Preparation of plaster

The principle of plaster slopes The material for finishing can serve as wood and PVC, as well as special plaster mixes. Slopes made of wood will be environmentally friendly, unlike plastic ones.

The principle of plaster slopes The material for finishing can serve as wood and PVC, as well as special plaster mixes. Slopes made of wood will be environmentally friendly, unlike plastic ones.

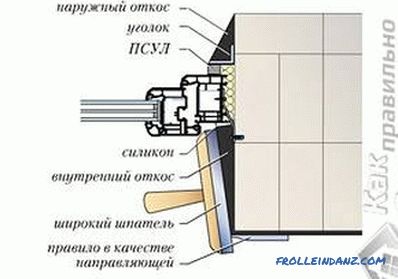

For wooden doorways, wooden slopes are more often used, and for window finishing, plastic materials are more suitable. One of the most durable and environmentally friendly slopes are plastering. Due to the lack of joints and edging products become the most attractive. This type of finish is most advisable to perform in new buildings at the same time with plaster walls, since such work is quite dirty and time consuming. When replacing windows, the most suitable option would be to install plastic PVC panels. Work with such materials is much cleaner, and in time it will take no more than a day.

Finishing process

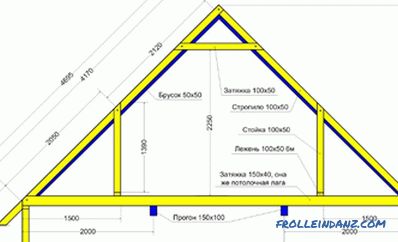

Plastering scheme

Plastering scheme

Alignment of door slopes Before plastering door slopes, you must ensure that the installation is secure. Then you can proceed to the preparation of the mixture. The solution for such works should be prepared at the rate of one to three (cement spade and three sands).

Alignment of door slopes Before plastering door slopes, you must ensure that the installation is secure. Then you can proceed to the preparation of the mixture. The solution for such works should be prepared at the rate of one to three (cement spade and three sands).

Plaster of slopes is a classic. There are situations in which it is simply impossible to do without finishing in this way. Such situations, perhaps, include the processing of almost all arched windows, because for such surfaces it is almost impossible to make slopes of other materials. The immediate advantage of plaster can be considered the fact that it gives the opportunity to process any form. In addition, it is resistant to external mechanical influences, environmentally friendly and easy to repair or upgrade. In addition, the solution will fill all the gaps, which will give the integrity of the structure and provide additional insulation. Before starting to finish the doorways, you must install the box, plaster the walls, then proceed directly to the slopes.

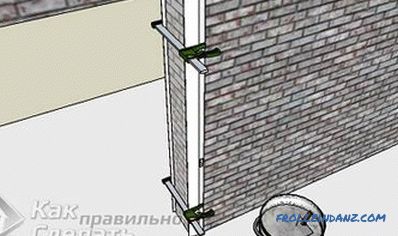

Guides for plaster

Guides for plaster

Work Scheme In most situations, jobs are done using a template. You can make the desired pattern from any durable sheet material. But quite often there are cases when the doors are not installed at all, and the door slopes are still plastered. How to be in this case? To begin with, metal plastering corner profiles should be installed on both sides, which will then serve as additional protection of the corner from external negative influences, and fill the resulting space between the profiles with mortar (remove the excess immediately). After everything is dry, you can begin to finish finishing the slope.

Work Scheme In most situations, jobs are done using a template. You can make the desired pattern from any durable sheet material. But quite often there are cases when the doors are not installed at all, and the door slopes are still plastered. How to be in this case? To begin with, metal plastering corner profiles should be installed on both sides, which will then serve as additional protection of the corner from external negative influences, and fill the resulting space between the profiles with mortar (remove the excess immediately). After everything is dry, you can begin to finish finishing the slope.

Before you start painting or pasting thin wallpaper, the surface is pre-puttied.

Arched slopes

Plastering arched opening

Plastering arched opening

Arch plaster

Arch plaster

The side portions of the arch are plastered similarly to the door slopes without doors installed, that is, using corner profiles that are installed on both sides of the opening. Additional attention requires only the upper rounded part. To do this, you should mark the location of the edges of the arch on the finished slopes. Arch bending should be strengthened with wire or thin reinforcement. For further work you will need a couple of templates, they can be cut out of plywood or some other durable sheet material. Templates are cut with the task of the required rounding radius and attached to the wall with the help of dowels. After which the resulting void is filled with mounting foam. A plaster mortar is pounced over the top of such a structure. With the help of a special semicircular trowel, the radius of the arch is displayed by templates. After the arch is completely dry, the patterns are removed and you can start painting or pasting the arch.

Before painting, all surfaces are puttied.

The process of plastering doorways is not a big deal. But in order for the slopes to turn out even and beautiful it is necessary to have patience and perseverance. Also used for leveling drywall. The use of such material does not require special skills. Drywall is easy to install without much effort. The only difference between these slopes is the quality and durability.

Video