Absolutely any owner of a cottage or a country house is faced with the need to arrange a canopy for his iron friend. This circumstance is primarily due to the versatility of the design, since it can be used not only for the car, but also for storing garden accessories and small technical devices. In addition to this, this building becomes more relevant when it is necessary to park the vehicle for a small amount of time. In the article we will tell how to make a metal canopy with your own hands for the car, we will provide step by step instructions, photos and video footage.

Design features and variety of its types

Before construction work, determine the future location of the shed, its style, determine the purpose and type of construction to be constructed. In addition, it is worth making a choice between stationary and mobile views.

The advantages of stationary construction are practicality and durability, and mobile - mobility. However, a movable canopy requires the manufacture of a solid frame, so it is built in rare cases when it is necessary to temporarily protect the car from precipitation, direct sunlight and dust.

By type of placement, awnings are detached and made as an extension. Attached structures form a single structure with a nearby building and are often combined with a common roof.

A simple canopy in the parking lot

A simple canopy in the parking lot

The roof of a free-standing canopy can be domed, arched, arched, lean-to and gable.

Conventional metal or shaped pipes, bricks and wood can be used as support pillars. At the same time, roofing materials also abound in diversity: decking, natural tile, polycarbonate, metal tile, etc.

The type of canopy and material determine the complexity and duration of installation of the structure. As a rule, for a simpler and more economical assembly using metal profiles and corrugated flooring. The thickness of the pillars and floors is selected depending on the size of the structure and the expected load.

Preparatory work

To successfully complete the task, you need to make an approximate sketch of the future shed, prepare the tool, purchase consumables and accessories. Required tools:

- construction level and tape measure;

- grinder or saw for metal cutting;

- drill with perforator and drill bit set;

- klepalnik;

- metal screws or rivets.

A complete and objective assessment of the quantity of consumable material, as well as the required amount of fasteners, depends on the precise drawing up of the drawing, therefore, the drawing up of the named document should be paid special attention. In addition, do not forget about safety when working with metal products.

Site preparation

When starting work, it is worthwhile to prepare the site for the structure. To do this, according to the sketch, we level and compact the ground at the site of the intended construction. Then we dig holes along the perimeter for support columns with a depth of 50 to 100 cm. Recesses are equipped in such a way that a rectangle is formed, usually in two rows of 2-3 holes.

Installation of supports

The metal profile should be cut according to the number of support pillars, their length should be 3 m. Depending on the type of construction you choose, the method of fastening the racks is determined . During the construction of a stationary canopy, the supports are installed on the level and concreted, while the construction of its movable counterpart requires additional cutting of metal pipes with a diameter somewhat larger than that of the supporting pipe and a length equal to the depth of the foundation. Prepared metal pieces are mounted in the pits and filled with cement mortar. Then a profile is inserted into each of the pipe cuts. Holes are drilled in the pipe and profile, and the entire support is bolted together.

Roof Installation Process

Roof Installation Process

You can use the described protective methods to impart rigidity and prevent premature destruction. "covers" and at arrangement of a stationary design. The only difference from mobile canopies will be that the profile must be welded to a metal pipe.

Roof construction

Roofs are one-piece and collapsible. Their primary difference lies in the method of fastening the elements together: in the first case, the component parts are welded, and in the second, they are bolted together. In addition, the designs are odnoskatnymi and gable.

Fastening of trusses with threaded connections

Fastening of trusses with threaded connections

For an example of a non-separable gable roof, consider the technology of its installation.It will be necessary to weld pieces of a metal profile to support columns in such a way that a correct rectangular frame is obtained. Then, we start welding rafters. On the ground, to the beam with one and the other side, we weld pieces of a metal profile with a step of 1 m at an angle of not more than 30º. It is important to bear in mind that the resulting structure must somewhat protrude beyond the limits of the welded upper frame. Next, place the welded elements on the supporting rectangle, boil in the joints.

Roof trusses

Roof trusses

To simplify the procedure for constructing a roof frame, reinforce the metal rectangular base, located on the supports, transverse beams in the center of each side. Then we weld 20–30 cm of section of the profile pipe to the central safety beam, which will act as a support for the future skate. Further pipes from a profile the increased pieces fasten with each other and the rectangular basis.

Roofing

Roofing

Having finished with the installation of the frame, we proceed to the covering with a professional flooring. The sheets are fastened directly to the prepared frame on the rafters overlapping each other by means of rivets, self-tapping screws or bolts.

When self-fabricating a carport, it is important to follow the instructions and observe the dimensions of the constituent elements reflected in the prepared drawings based on accurate calculations. All these conditions, together with the right approach and due diligence will allow you to build a high-quality metal canopy.

Video

In this video, it is more detailed about the intricacies of manufacturing a metal canopy:

Photos

On photos you can see various options for arranging a metal canopy:

Arched metal canopy

Arched metal canopy

A canopy in a private house

A canopy in a private house

A canopy with forged posts

A canopy with forged posts

Above the porch

Above the porch

Above the stone grill

Above the stone grill

Canopy arbor

Canopy arbor

Metal canopy on brick supports

Metal canopy on brick supports

Metal canopy at the cottage

Metal canopy at the cottage

A small canopy over a brazier

A small canopy over a brazier

Gable canopy

Gable canopy

Schemes

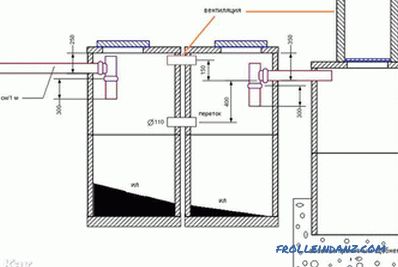

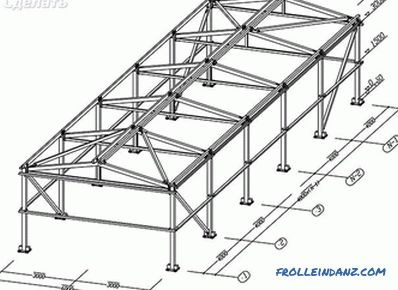

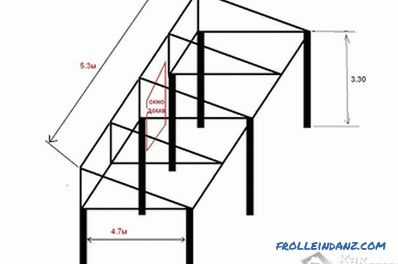

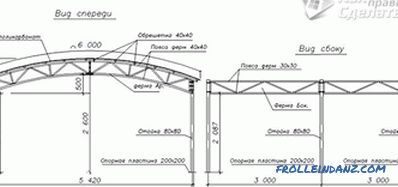

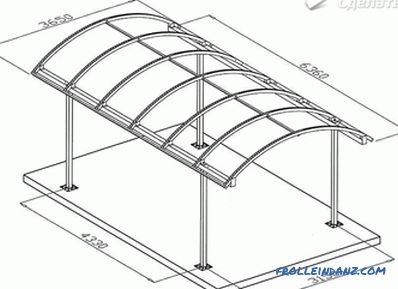

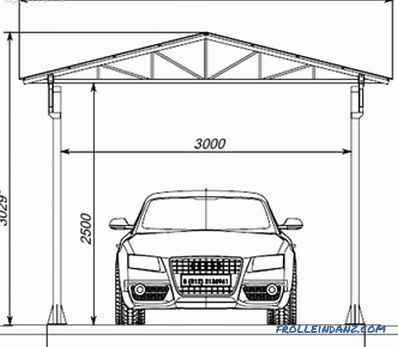

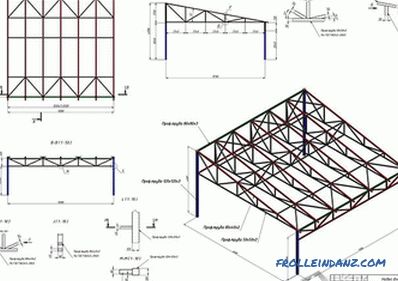

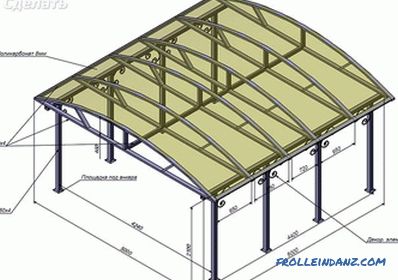

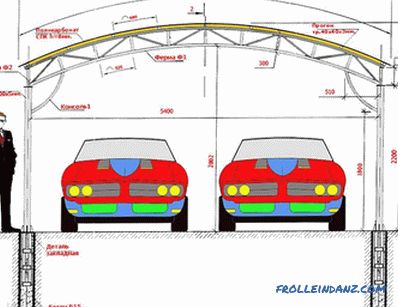

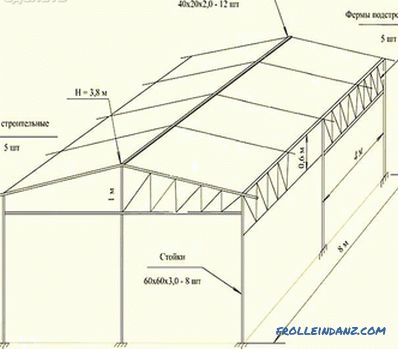

If you decide to make a metal canopy, then the provided scheme can help you in making a suitable construction for you:

Metal construction drawing

Metal construction drawing

Drawing truss truss

Drawing truss truss

Scheme of a shed

Scheme of a shed

Front and side view

Front and side view

Metal canopy scheme

Metal canopy scheme

The scheme of the gable roof

The scheme of the gable roof

Workshop canopy drawing

Workshop canopy drawing

Arched canopy scheme

Arched canopy scheme

Carport for

Carport for

Canopy design

Canopy design