In everyday life, not so often a person has to drill glass. However, such a need sometimes arises if, for example, you need to fix a mirror or make a structure consisting of glass shelves. Glass is a very fragile material, so when it is drilled in the living conditions you need to follow certain rules. If you carefully and carefully perform this work, then you can make a hole in the glass yourself. At specialized enterprises in this fragile material they drill holes using special machines using special tools. At home, this fine work can be done using other, simpler ways. On the question of how to drill glass, there are many answers.

Tools for drilling glass

Drill bits

Drill bits

First you need to decide on with a drill, which, according to its physical and mechanical capabilities, can, without prejudice to the final result, make the required hole.

- We can immediately say that technical equipment, which has proven itself in the processing of metal or wooden workpieces, is not suitable for drilling glass material. The traditional drill will not perform its task in this case, and the sheet of glass at the drilling site will generally crack and become unsuitable. For such a specific material, special drills with a sharp (diamond) tip are provided, which, thanks to their design, are gradually cut into glass. This process contributes to the deposition on the tip of the arrow drill. Thanks to this form of drilling, drilling takes place slowly and without prejudice to the final result.

- In the data processing industry, tubular-shaped drills are also used, which are treated with diamond cutting chips — they can easily cut glass material. The cutting edge of such a tool has a hardness indicator of more glass, so the tip penetration occurs slowly but surely.

- In everyday life, a conventional drill is most in demand, during operation of which there is an opportunity to adjust the speed of turns. Glass, as a rule, is drilled at a low speed of rotation of the drill with mandatory cooling of the surface.

Tool

Tool

You need to know that when drilling tempered or reinforced glass you need to apply a lot of techniques. For the high-quality performance of such work, it is advisable to contact workshops that possess special equipment.

Use of a Drill

Glass can be drilled with a drill, but only if the material is free of fat deposits with alcohol or turpentine. After cleaning the surface to be treated, allow time for the cutting edge to dry. After that, the glass is laid on a flat wooden table, while the edges of the material should extend beyond the base. After that, the places intended for drilling are stuck with construction tape. On the scotch tape is made, which should coincide with the center of drilling.

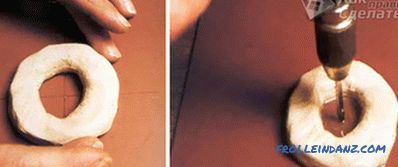

Tray of clay

Tray of clay

Do not immediately make the first hole in the material that you are going to drill - to learn how to drill glass, for the sample, you can use a small piece of glass. During the work it is not necessary to create excessive pressure on the drill, since the material must be drilled with a small feed. Sometimes a deceptive feeling is created that the glass is not drilled, while the drilling is on its own. When drilling, one should not forget that the contacting materials heat up, so it is advisable either to cool the drilling site with a periodic supply of water from the spray gun, or to make a bath of plasticine at the drilling site and pour a small amount of water there. Also, it should not be forgotten that the drill should be perpendicular to the material.

First practice

First practice

Thin moment - as soon as the drill overcomes half the thickness of the glass, the material must be turned over the other side, and continue drilling from the opposite side. This simple technique will avoid cracks and chips. After the hole is formed, its edges must be treated with sandpaper with fine abrasive.

Keep the tool perpendicular to the glass

Keep the tool perpendicular to the glass

Alternative methods

Humanity is distinguished by its resourcefulness - and in this case, if there is no appropriate tool, at least one of the methods described below can be used to make a hole in the glass.

Methods for drilling glass

Methods for drilling glass

- The task is to drill a hole in the glass with a diameter of up to 4 mm. For this operation, the usual drill bit, but pre-hardened, is suitable.The drill is clamped with pliers, fed to the flame of a gas stove, and kept for as long as the tip warms until white. Then the heated part of the drill is placed in sealing wax. When the cooling material stops foaming, the drill can be removed. Quenching and cleaning the drill mechanically from wax can get to work.

- If the hole needs to be drilled in a small glass object, then before starting work, it should be dipped in cold water, which is in a container of appropriate size. Water should barely cover the surface of the glass device being processed. The main thing is that the product before processing was not able to move.

- The following exclusive method is intended for carbide glass. To make a planned hole with your own hands, the drill must be moistened with a rag soaked in a mixture of turpentine and camphor. After that, the product is made of plasticine, the inner circumference of which is intended for pouring the prepared liquid into it.

With this method of processing glass in living conditions it is recommended to lay the material on a soft cloth.

- In the absence of a drill, a piece of copper wire can be inserted in the socket of the chuck, and the drilling process will be carried out using this piece. For high-quality drilling, the abrasive powder is stirred in camphor, after which it is dissolved in turpentine in a ratio of 1/2 and a hard emery paper surface is added to the resulting mixture. Mixed composition is applied to the point of drilling, then you can get to work.

- In practice, another method has proven itself at its best. A copper or aluminum tube is taken up to a length of 60 mm. After that, at one end of the pipe a wooden plug is attached, with the other moans teeth are cut out. Then a screw is twisted into the cork, the cap of which you need to saw off. Then small cartons are glued to the glass at the point of drilling on both sides, the size of which should coincide with the diameter of the hole. The drilling site is covered with abrasive fine material. The next step - the screw is inserted into the tool holder, the teeth are lubricated with turpentine. After these procedures, a hole can be drilled, which should reach a third of the plate thickness. After that, the glass must be turned over and the work continues from the opposite side.

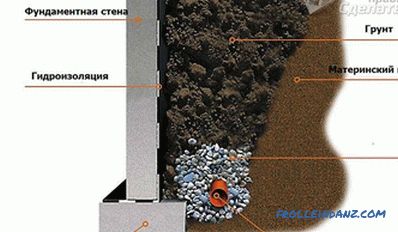

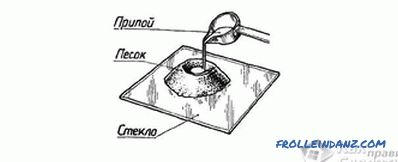

- The last and most effective method of drilling this material at home is to take out the desired glass circumference using lead or tin solder. A hill of sand is poured in a certain place, then the surface of the desired diameter is cleaned with a pointed stick at the point where the hole is made, after which hot tin or lead is poured into the free space. The metal elevation is drawn out along with the glass fragment.

With the help of tin or lead

With the help of tin or lead

There are other methods for drilling glass. But you can stay on these practical and ingenious methods.

Video

Clearly, the drilling process is shown below: