Problems with a plumbing, gas or sewage system often involve installing pipes — replacing a piece of an old pipe or installing a new one. In carrying out such work, you will need skills in determining the diameter of the pipes of your system by improvised means. When installing a new water supply system, it is also necessary to accurately determine the size of old pipes in order to determine the choice of new plastic or metal-plastic pipes.

Of course, there are special tools for making such measurements, for example, a laser meter, a ruler, a circometer, and others. But what if you are not a professional and you don’t have such precision instruments in your home tooling? How to measure the pipe diameter in a different way?

Before answering this question, it is useful to know in what units these indicators are measured. The diameter of the pipe is usually measured in inches. One inch equals 2.54 centimeters.

When working with a pipe, both its inner and outer diameter will be measured. The outer diameter of the pipe is important due to the fact that it is its value that is taken into account when applying the thread and creating threaded connections. The outer diameter is in direct proportion to the wall thickness of the pipe. The size of the wall thickness is the difference between the outside and inside diameter of the pipe.

From words to deeds

From words to deeds laser bracket

From words to deeds laser bracket

There is several methods of measuring pipe diameters, differing in their characteristics depending on the conditions that are important to consider in order to avoid errors. The choice of a particular method of measurement often depends on the availability of the object of measurement. Consider some of them.

Pipe measurements with improvised means

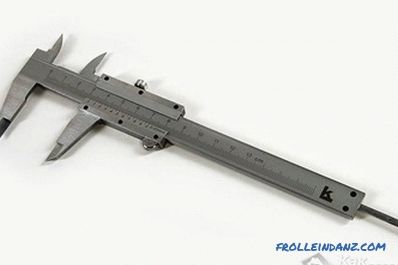

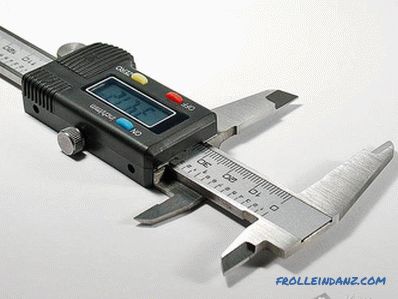

Most commonly, a well-known caliper is used to measure pipe diameter. But you may not have it, or if it is present, it is not possible to measure a large pipe diameter with its help. In this case, the simplest set of tools and knowledge is used:

- flexible ruler (like measuring tape used in sewing);

- tape measure;

- school knowledge Pi numbers (it is 3.14).

With this set of tools you can measure the diameter of not only the pipe, but also any other round object - a rod, column or garden bed.

We need to make only one measurement - to determine the pipe circumference using a tape measure or flexible ruler. To this end, a centimeter tape or tape measure is placed on the surface of the pipe in its widest part. The resulting value of the circle should be divided by 3.14. For more accurate dimensions apply the value - 3.1416.

It should be noted that import deliveries of pipes are accompanied by documentation in which the values of pipe diameters in inches are already indicated. To convert these values to centimeters, they are multiplied by 2.54. Similarly, for converting centimeters to inches, multiply by 0.398.

Measurement of small-diameter pipes

Measurements are made using calipers without any mathematical calculations. The condition is full accessibility to the pipe. This method is suitable for measuring available pipes of small diameter (no more than 15 cm). To perform the measurement, the caliper legs are applied to the pipe end and are clamped tightly on the outer walls. The obtained value on the caliper scale with an accuracy of tenths of a millimeter will be the outer diameter of the pipe.

Measurement of inaccessible pipe

If the end of the pipe is not available for measuring, that is, when the pipe is an installed element of an already existing water or gas supply, For measurements, a caliper is applied to the side surface of the pipe. In this case, an important condition for the measurement: the length of the legs of the caliper must exceed half the diameter of the pipe.

Measurement of a large diameter pipe

Measurement of a large diameter pipe

Measurement of a large diameter pipe

Above, we already Mentioned formula with value. Measurements of the circumference of a large pipe can be performed using a cord or tape measure, and then its diameter is determined by the formula D = L: 3.14, where: D is the diameter of the pipe;

L is the circumference of the pipe.

For example, if the length of the pipe circumference measured by you was 31.4 cm, the pipe diameter will be D = 31.4: 3.14 = 10 cm (or 100 mm).

Measuring pipes using photography (copying method)

Measuring photography

Measuring photography

This nonstandard method is applied when completely inaccessible to a pipe of any size. A ruler or any other object is applied to the measured pipe, the dimensions of which are known in advance to any master (often in this case a matchbox is used, the length of which is 5 cm, or a coin).Further, this section of the pipe with the attached object is photographed (except for the camera, in modern conditions, the use of a mobile phone is also available). The following size calculations are made from photographs: the image measures the visual thickness in mm and then translates it into real values, taking into account the scale of the photos.

Determination of the internal diameter of the available pipe

Determination of the internal diameter

Determination of the internal diameter

Using the normal ruler or caliper measure the wall thickness of the pipe at its cut. This value, multiplied by 2, is subtracted from the outer diameter values. The resulting value and will be equal to the internal diameter of the pipe.

Monitoring of pipe parameters under production conditions

Production control of pipe parameters

Production control of pipe parameters

Outdoor the diameter of water supply or sewage pipes under large production conditions is monitored and checked using a more sophisticated formula: D = L: 3.14 - 2∆p - 0.2 mm.

In this formula, besides the already known values, the ∆p symbols mean the thickness of the tape measure in mm, which you use for measuring the diameter, and "0.2 mm" from the formula are the tolerances taking into account the fit of the tape measure to the pipe. The tolerance for pipes with a 200 mm cross section is ± 1.5 mm.

When measuring large diameter pipes, the tolerances are measured in percent. Example, for products with sizes from 820 to 1020 mm, the tolerance is 0.7%. For such measurements, an ultrasound based measurement setup is used.

The thickness of the pipe walls in large production conditions is measured with a caliper with a scale division of 0.01 mm. The permissible deviation from the nominal thickness in the direction of reduction should not exceed 5%.

The curvature values of the pipe are also subject to monitoring, which should not be higher than 1.5 mm per linear meter of pipe length. The total curvature of products in relation to its length should not be more than 0.15%. The ovality of the pipe ends is determined by the ratio of the difference between the largest and smallest diameter to the nominal diameter of the pipe.

The value of this parameter should not exceed 1% for pipes with a wall thickness of up to 20 mm and no higher than 0.8% for walls above 20 mm.

The pipe ovality can be determined by measuring the diameter of the pipe end using an indicator bracket or a caliper in two mutually perpendicular planes.

Simple school knowledge and careful use of simple tools will greatly simplify your task - how to measure the pipe diameter with improvised means.

Video

We suggest watching a video about working with measuring instruments.