Interior doors can take various forms, but it is not at all necessary to spend large sums on their acquisition. To completely transform the interior, the doors can be completely done by hand in any desired style. The work is not very difficult, but requires some experience and attention.

You will have to spend large amounts of money to purchase doors to each room, so a rational decision would be to make them yourself.

It is important to correctly determine the dimensions of the shield and the web, so that the door opens and closes normally during operation, and there are no distortions . Do-it-yourself wooden doors can be made by pre-selecting materials for work, making a scheme.

Options for interior doors

Diagram of types of interior doors.

Interior doors, the installation of which is not very complicated, may have a different type of design and appearance. The most common designs are:

- paneled simple doors, easy to assemble;

- panel doors;

- massive deafs;

- with stained glass and other inserts .

The doors may differ by the following features:

- On ordinary door hinges, the adjustment of which will not cause problems. Such a constructive option is most common.

- Special sliding doors, which are mounted on rollers or skids.

- Folding doors that look like an accordion.

The following materials are used for the door itself:

Wooden interior doors are the most practical, since they can be painted, varnished, pasted etc.

- Wood. It features a pleasant appearance and a minimum of finishing. Such structures after installation can be painted, varnished, stain and oil. The cost of a wooden door will be significant, especially if expensive wood is used, decorative inserts from natural stained glass are used.

- The simplest models are made of wood panels, they are relatively inexpensive, and it is easy and quick to work with such raw materials. After installation, a decorative finish is required.

- There are options when wood is used only for the frame, and glass panel is used for the front sheet. You can make such a door with your own hands, but experience is needed for this. It must be remembered that its finishing is complex, requires care, as the glass is easy to break.

You can also use other types of materials that are great for decorating. All require compliance with appropriate assembly technology. If a sliding door is to be made, then it is necessary to additionally arrange runners for rollers, along which the door will slide apart.

Preparation for work on the manufacture of the door

Scheme for taking measurements of the doorway.

Preparation for work includes all measurements and the acquisition of necessary materials and tools. Measurements are performed in the following sequence:

- Measurement of the length and width of the future door leaf and door frame.

- Determination of the thickness of the canvas, the need for platbands, decorative stitching too wide the end of the wall.

Of the tools for work, you must prepare:

- boards made of wood with a thickness of up to 50 mm, which are necessary for making the box;

- bars and slats for the frame of the canvas;

- material for the facial finish: it can be wood or plywood panel, fiberboard and other types of raw materials; if you have experience, the panel can have threads, glass inserts;

- self-tapping screws, nails, metal corners, wooden spikes;

- wood glue for woodworking;

- decorative items, if they will be used;

- electric jigsaw, saw;

- hammer;

- drill;

- chisel set;

- accessories for the door (handles, door hinges, locks, etc.).

Making a door with your own hands

Making a wooden door is carried out in the following order:

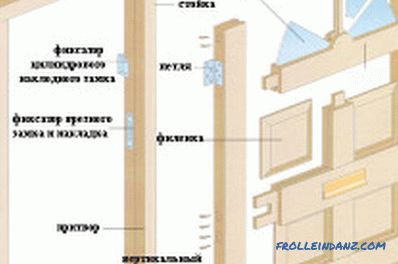

Wooden interior door assembly scheme .

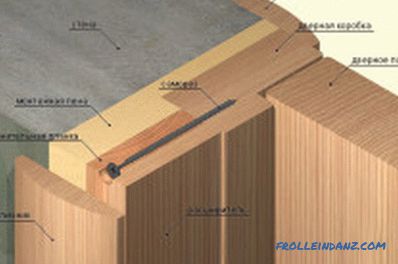

- First, you need to create a sketch of the future construction, make measurements of the doorway. At the same time, while drawing up a drawing, it must be remembered that the dimensions of the future door structure will be approximately 1-2 mm smaller than the existing size of the box. This is done so that after installation the door opens and closes easily, there are no difficulties in its use. After the installation itself, all left slots and cavities between the wall and the door frame must be carefully filled with mounting foam.

- When the drawing is ready, you must proceed directly to making a wooden door with your own hands. First you need to assemble the frame of the future design, for this purpose bars are used. Two solid bars with a width of 10 cm should be cut to the height of the opening.The thickness of such bars should be 5 cm. Cut 3 transverse bars to the size of the width of the opening. These boards are stacked on a previously cleared floor, 2 long beams are mounted from below, and 3 transverse beams from above in such a way that a rectangular door-like structure is obtained. At the site of the future castle should be placed bar, whose thickness will be approximately 35 mm. This is necessary to strengthen the design. During the compilation of the frame, one must also remember what the facing will be, whether the glass is used, whether the plain blank panel will be mounted or with decorative inserts.

- During the formation of the frame, experts advise the use of a wooden construction corner that ensures the evenness of all the corners. Even the slightest bias will not allow the door to close completely. The boards are marked for connecting studs and other fastening elements, holes. After this, the evenness of the corners and dimensions are checked again.

- When the check is completed, the connection of the box elements begins. To do this, the joints are coated with glue, wooden fasteners and screws are fastened. Corner parts can be further strengthened with metal corners to give stability to the door leaf.

Installing the door leaf

The frame is pressed down with a load and left for about 2 hours. At this time, you can proceed to the manufacture of facial cloth. It all depends on what kind of appearance you need to give the door in the future. Wooden door with their own hands can be made in the form of a deaf panel.

The canvas can be painted with stain or varnish, it must be reinforced with a cross bar.

The frame of the door frame.

You can also use doors with glass inserts and one-piece glass panels. During assembly, you need to remember that for door hinges, locks, handles, you need to correctly determine the place, then perform the cuts and holes for installation.

The first installs the door box, it is attached to the walls with screws and anchors. It is necessary to use the building level to check the horizontal position. Before the final installation will be carried out, it is necessary to check everything, only then begin the fasteners. Next, you need to mount the hinges, focusing on where exactly the points for them are located on the door leaf. It should accurately determine the location of fasteners. Installation begins only after everything is checked. The last installation of handles for linen and lock. Instead of the traditional lock, a conventional latch can be used, it all depends on the purpose of the door.

It is not so difficult to assemble a wooden door with your own hands, but for this you first need to make a drawing and choose materials for work. During assembly, it is important to follow all recommendations exactly, otherwise misalignments are possible.

Didn't find the answer in the article? More information on the topic:

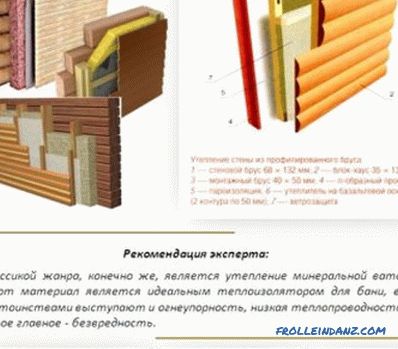

-

How to properly heat a log house

Instructions and detailed description of the process: how to insulate a log house. Practical recommendations. The device ventilated facade technology log house insulation.