The fence of any private house is a business card. Due to the huge amount of materials and innovative technologies, anyone can build not a simple fence, but a real decorative element that will add to the attractiveness of landscape design. One of those is the wrought-iron fence that will look most impressive: the graceful lines and the openwork weave of metal rods captivate with beauty. Naturally, if you order such a fence from professional craftsmen, it will cost a lot. You can make such a design yourself, since this is a quite feasible task, despite the complexity of the processes. It is enough to consider all the main points of the assembly and the question of how to make a wrought fence with your own hands will be resolved.

Features and advantages of forged fences

There are undeniable advantages of a forged fence over its counterparts made using other technology and other materials:

- Reliability. As you know, metal is one of the strongest and most durable materials. If it is processed according to all the rules, the design will easily withstand changes in air temperature and high humidity. With proper care, the life of forged fences will be unlimited.

- Appearance. If you consider other types of materials from metal sheets, they will have a different appearance. Forged fence, regardless of the style of the house and landscape design will always look modern and noble.

- Variability. Thanks to the flexibility of the metal, any shape can be created from it. This directly affects the completeness of the infield. The design will give it luxury, inaccessibility and elegance.

Basic technologies

Many consider that it is necessary to involve craftsmen and professional blacksmiths to create a wrought fence. In addition, the majority refuses this idea because of the need to work with special equipment, which requires special skills. But today you can get a wrought-iron fence in one of three ways:

- welding is an affordable way for every person;

- forging means connecting all elements of the fence manually, therefore it takes a lot of time and strength, as well as the acquisition of certain skills;

- combined option - combines the first and second technology, therefore, equipment and skills are needed.

Fences made of forged elements are considered to be a real work of art, as they are created by metal artists. Due to the variety of decorative elements, as well as metal processing techniques, everyone can choose a suitable option for themselves. It is worth noting that today the most common are sectional fencing, which can be bought in specialized companies. They are quite easily and quickly mounted without the involvement of professionals.

By deciding to make a fence from forging with your own hands, you can save money and also get a fence, an analogue of which will be difficult to find.

The necessary tools for working

Before you begin, you need to pick up all the tools:

- Bulgarian;

- welding machine;

- vice;

- device for twisting metal rods (longitudinal and transverse);

- spray gun with compressor;

- other small tool.

To protect the forged sections from the influence of precipitation, it is enough to open them with paints and varnishes. In most cases, use a combination of black and gold hues.

Making a wrought fence at home

No matter what material was chosen for the base of the fence, it can be supplemented by spans of finished elements forging. So, very often you can find a combination of brick and stone with metal. At the request of the fence can only be made of forged elements.

Each span should be fixed on the supporting pillars, which are installed when forming the foundation. The gate and the gate must also be made of forged elements. This will complement the given style.

Like any other fence, forging requires a reasonably solid foundation. In its role stands the foundation. It is enough to use tape technology, which is quite simple and does not require the acquisition of any special skills.

Features of the construction of the design

From which side not to look at the fence with elements of forging has practically no flaws. There is only one - the high cost. But, if it was decided to do it yourself, then this problem is solved. Today, innovative technologies can solve almost any problems associated with home improvement. The same applies to fences.Forging can be performed in two ways:

- hot;

- cold.

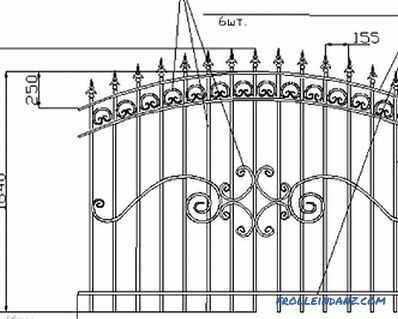

Hot technology is used only by professional forges, so newcomers in this matter should prefer the cold production of forged fences. To begin work with the selection of the picture. To do this, you can use a huge number of options and ideas of the masters or develop your own sketch. If this is your first time contacting such technologies, then you should not dwell on complex and jewelry-requiring versions.

After the pattern has been selected, you can start marking the future fence. It is important to maintain the same distance for spans and support posts. This will allow you to calculate the number of sections and calculate the necessary materials.

If you can, you should seek help from a blacksmith or a professional who will show some basic techniques and also give lessons for beginners.

Preparatory work for the implementation of the combined technology

Runs made from forging will be much cheaper than their decorative counterparts. After all the calculations have been done, and the markings have been applied to the territory, you can proceed to the preparation.

First of all, you need to do the foundation. The depth of the foundation trench should not be deeper than 30 cm. Also, do not forget about the sand cushion, waterproofing and formwork. During the pouring of the foundation for reinforcement, reinforcement is laid and metal reinforcement for the pillars is removed. The most durable and reliable option is to install the pillars in a trench, followed by welding them with a reinforcing frame and concreting.

The fence support pillars must be installed strictly vertically, therefore it is necessary to constantly check the level of clarity. During construction, the tops of the pillars are covered with a film so that water does not get into them before the construction is completed. For greater protection, you can purchase decorative waterproof caps.

Brick and concrete pillars are very well combined with wrought spans. You can also consider the option with a simple metal support structures.

The main stage of work

During the solidification of the foundation, it takes about a week, you can start making forged spans. To do this, using the grinder cut pieces of metal of the required length. All of them will be smooth, and to give them the desired shape, you need to use tools for cold forging. Subject to technology and accuracy, all elements will be the same in shape and size. Particular attention should be paid to the ends of the parts, as they have an acute shape. To solve this problem, you can use two methods:

- round them in;

- use metal balls.

Balls can be purchased or made yourself. The optimal size will be a diameter of 2 cm. When all the elements are twisted according to the picture you need to expand them all and view. This will immediately determine which parts are too different and require rework. The construction of the structure begins with the creation of a frame, for which pipes with a cross section of 25x25 are chosen (size 30x30 is also allowed). After the frame is fully welded, it is necessary to lay out all the elements, this will allow you not to get confused and complete the drawing.

At the end it is necessary to check the span for the presence of errors in the form of large seams. If necessary, everything is cleaned with metal brushes. It is advisable to do this with the entire product. The final stage involves staining, but before that they carry out the degreasing and priming, so that the paint lies in a uniform layer. The paint will protect the metal from corrosion, as well as give completeness to the fence.

Experts do not recommend collecting runs on weight. For this fit the table. During welding, the main elements are welded first, and then decorative elements are added to them. Painting is done after the installation of metal spans between the pillars.

It is enough to set aside a little time, apply imagination and strength, study this article and be patient to make an original forged fence. Due to this, costs can be significantly saved, since when ordering such a fence in specialized companies, the amount will be several times higher.

You may also be interested in the following material:

Fence made of corrugated flooring with your own hands

How to make a fence from unedged board

How to make a fence from a shaped pipe

Fence of stone with their own hands

How to make a braided fence

Video

From the provided video material, you can get acquainted with the intricacies of making a forged fence:

Photos

The following is a series of photographs showing forged fences in a variety of designs:

Forged gate, fence and wicket

Forged gate, fence and wicket

Forged horseshoe fence

Forged horseshoe fence

Forged geometric fence

Forged geometric fence

Combined wrought fence

Combined wrought fence

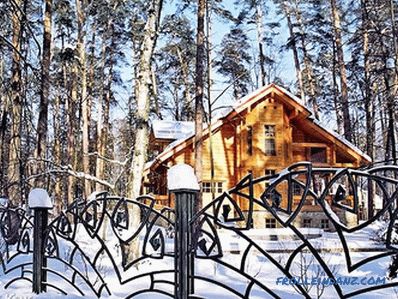

In a country house

In a country house

Forged fence in a private house

Forged fence in a private house

Small forged fence

Small forged fence

Beautiful example

Beautiful example

Non-standard forged fence

Non-standard forged fence

Unusual forging

Unusual forging

Simple with forging elements

Simple with forging elements

Original forging

Original forging

Stylish forged fence

Stylish forged fence