Modern apartment owners increasingly prefer free movement in the kitchen, the possibility of which is achieved through redevelopment. So, many seek to improve the interior and at the same time make each area functional in this room. The association of a kitchen with a dining room is becoming increasingly common, and a bar counter is used as a dividing element between them. Given the unusual height of the rack in contrast to the usual, the chairs for the rack should be ordered or manufactured individually. In this article, we suggest you familiarize yourself with several technologies of how to make a bar stool.

Height

The height of the chair

The height of the chair

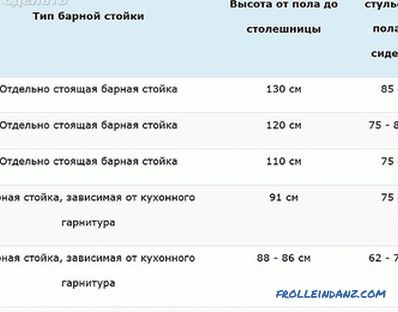

Bar stools have their standard sizes, the basis of which are the principles of ergonomics. In most cases, the range of their height varies between 75-85 cm. Although some manufacturers produce products of smaller sizes. In general, the height will directly depend on the height of the rack. Below are the tables on the ratio of the height of the table top to the chair:

The ratio of the height of the table to the chair

The ratio of the height of the table to the chair

So What should be considered when determining the height of a bar stool? Consider the main factors:

- Seated posture.

- Growth.

From array

Now let's take a closer look at an example of how to make a chair from solid wood. As for wood, the most accessible material is pine and birch. They are commercially available. When selecting, make sure that there are no knots and other damages. This is important, because the product ultimately should be quite durable.

So, for manufacturing, you will need to prepare the following blanks:

- Circle Ø360 mm and 30 mm thick 1 pc.

- Circle Ø260 mm and 20 mm thick 1 pc.

- 4 pcs. legs 30 mm thick.

- 4 pcs. stiffening ribs with a thickness of 30 mm.

Part 1 and 2

Part 1 and 2

Part 1 will serve as a seat. As for part number 2, it will play the role of the substrate under the seat.

When the legs are cut, make sure the wood structure is vertical, that is, the cuts are not made against the fibers.

Part 3

Part 3

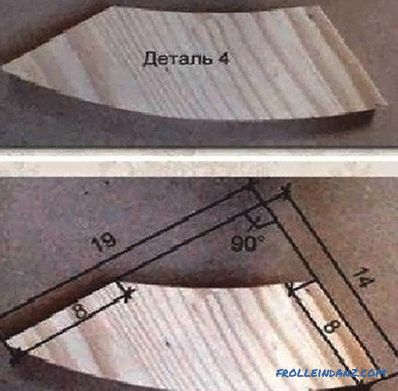

You also need to cut stiffeners, as indicated in the schematic figure :

Detail 4

Detail 4

To build this, you will need 3 types of screws:

- 5 * 80 mm - necessary for fastening the legs to a small circle.

- 5 * 40 mm - will be required to secure the main seat to a small circle.

- 5 * 20 mm - for fixing stiffeners.

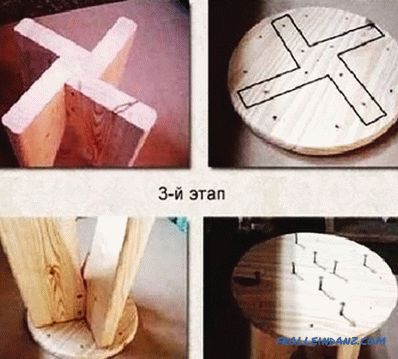

The build process is indicated step by step:

The build process

The build process

To prevent cracking of blanks, pre-drill holes for them.

At the end of the work painting is performed.

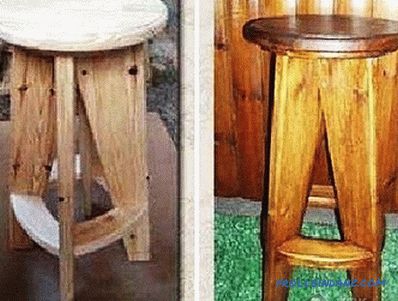

Ready wood bar stools

Ready wood bar stools

Made of metal

If you like metal products, then you can make a chair out of metal without much difficulty yourself. Now we suggest that you familiarize yourself with the manufacturing process with the help of a photo instruction.

To work, you will need a metal strip with a thickness of up to 5 mm. Having executed a small sketch on a cardboard, cut off strips of the necessary sizes.

This article does not intentionally specify dimensions, since in this case, everyone can make the seat of the chair at their discretion.

Welding the seat base

Welding the seat base

The strips are reliably welded together. Pay attention to the quality of welding. Although everything will be sanded later, it is important to apply a neat weld. From this, the appearance of the chair will only benefit.

Also at your discretion, you mark in the chaotic arrangement of the cross member inside the seat frame. Here it is important to ensure that there are not too large openings.

Filling the base of the seat

Filling the base of the seat

As well as the seat frame, you can scald all the cross-pieces. After that, remove each welding seam from the slag with a grinder with a grinding wheel installed on it, not forgetting to wear safety goggles.

To prevent injuries, smooth out all the sharp corners of the workpiece.

Making the legs

Making the legs

Next, you make legs from the pipes. They should have the same size, which can be determined from the table at the beginning of this article. All four blanks are welded to an already made seat. To enhance the design of welded cross. They will additionally serve to support the legs. Do not rush to weld thoroughly. First on the pot holders to try on everything and adjust.

Welding cross-beams

Welding cross-beams

If everything fits, you can carefully weld the parts.As a result, in a raw version, the bar stool will look like this:

Ready unpainted chair

Ready unpainted chair

If you leave the legs as they are, they will scratch the floor, they can smash tiles and, worst of all, make an unpleasant sound as they move. Therefore, wooden wedges can be hammered into the lower part of the legs, as shown in the picture below. So, you can increase the stability of the whole structure.

Increasing the stability of the chair

Increasing the stability of the chair

A kind of wooden "plugs" can not be attached. They will be held by friction and pressure. Be sure to fit the wooden workpiece so that it is flush with the leg.

Fitting wooden blanks

Fitting wooden blanks

When the bar stool frame is ready, you can paint it. Grind all welding points beforehand, and also make sure that there are no sharp protrusions. Apply primer.

Priming

Priming

You can paint the feet and the place in any color you like.

Painting

Painting

If you have your own ideas for making such furniture, be sure to write about it in the comments on this article. At the end we offer you to consider the drawings and photos of the finished bar stools. Perhaps you will find many interesting ideas for yourself.

Video

Photos

Plywood bar stools

Plywood bar stools

Standard bar stools without a backrest

Standard bar stools without a backrest

Steel bar stools

Steel bar stools

A wide bar stool

A wide bar stool

Bar stool

Bar stool

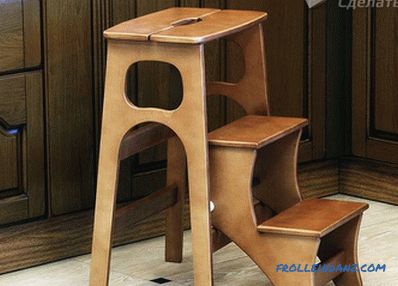

Another option with a ladder

Another option with a ladder

Wooden bar stool in the form of a bolt

Wooden bar stool in the form of a bolt

Bar stools made from recycled materials

Bar stools made from recycled materials

Bicycle chairs

Bicycle chairs

From glued laminated timber

From glued laminated timber

Drawings and diagrams

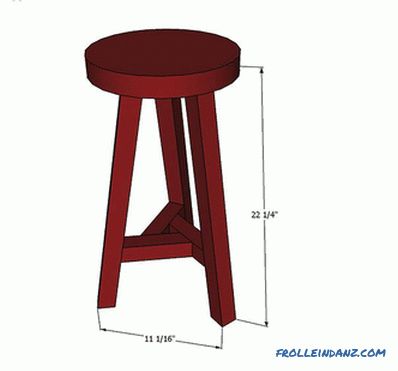

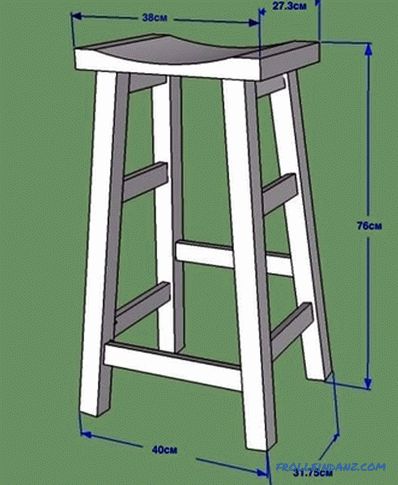

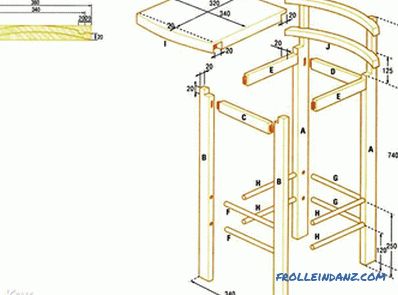

This subsection will help you understand the design features and details. Bar stools:

Diagram of a standard bar stool

Diagram of a standard bar stool

Size chart

Size chart

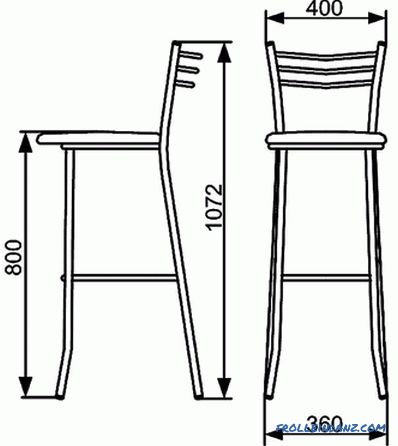

Scheme of bar stools with dimensions

Scheme of bar stools with dimensions

Drawing of a chair

Drawing of a chair

Drawing of a bar stool with a back

Drawing of a bar stool with a back