The ground floor is a fully or partially recessed floor of a building below ground level. As a rule, in such a room equip utility rooms or a garage for the car. However, individual projects of houses provide for a bath, sauna, gym, swimming pool, etc. in the basement. In some cases, the construction of the basement is an excellent solution, especially if the house is located on a slope. Due to this, it is possible to effectively increase the living space of the entire building. Therefore, if you have not started building a house, then it will be useful for you to familiarize yourself with the provided article, from which you will learn how to make a basement and equip it, and for what purposes it can be used.

Ground floor - usable area

The ground floor at the same time can serve as the foundation of the entire building and the living space. The main feature in its arrangement is to meet the requirements for size, strength and internal space. Thus, the regulated ceiling height should be at least 2.5 m. However, in some cases, the depth is limited by the presence of high groundwater. Therefore, the basement can be above ground level. In cases where groundwater is located deep, this room is completely hidden in the ground.

You should not assume that the basement is a basement. In fact, it can be fully considered a full-fledged floor, but only if it is properly arranged.

Rest room on the ground floor

Rest room on the ground floor

For example, if the groundwater is at least 1 m from the surface of the earth, then under the construction of digging the pit is not worth it. At the same time, the above-ground part of the basement should be filled up with soil. In this case, you can artificially deepen the ground floor. However, such a decision would entail large labor costs. In addition, it is also necessary to organize high-quality drainage around the building.

So, the basement can be used for the location of such premises:

- storage room;

- garage;

- wine cellar;

- game room;

- living room;

- bedroom;

- utility room;

- kitchen;

- living room;

- gym;

- home theater and more.

As you can see, there are almost no restrictions on how to use this living space. Another of the positive aspects of this room is that the insulating qualities of the whole house increase.

Types of socles

The base differs in its design and there are 3 types:

- bulging;

- recessed;

- flush with the walls.

If the walls are too thin and the rooms of the basement are below the ground level, then the first option is used, since it is possible to make it warmer. Recessed base is one of the most common. In appearance, it looks quite beautiful. Drainage of water that drains from the facade prevents the presence of high humidity. As for the recessed option, many construction specialists do not recommend building it. In this case, the effect of the presence of the basement is completely lost, and on the walls you will need to make a strong waterproofing.

Base flush with walls

Base flush with walls

There are some special features for choosing wall thickness. Mainly it will depend on several factors, namely:

- thickness and material of the upper walls;

- soil characteristics;

- climatic conditions in your region.

So, having decided on how the construction will be carried out and what type of base you want, you can proceed to the preparatory and construction processes.

Calculations

The stage of work associated with markup implies the following actions:

- Designing the ground floor, as well as determining destination of a particular room.

- Calculations for the bearing capacity of the foundation and walls of the underground floor. It is recommended to lay the foundation at 30% greater strength. Thus, it will be possible to have greater confidence in the strength of the whole structure.

- Clearing and marking of the construction site. This stage of work is quite responsible, so it is often better to contact qualified specialists.

- Removal of the contour of partitions and load-bearing walls.

How carefully you approach each preparatory stage will directly affect the strength of the structure.

Types of foundations

It is not always possible to create a foundation that you really want. The reason lies in the particular soil of a particular region. In some climatic zones, the arrangement of some types of foundation is generally impossible. Therefore, we consider several options for the foundation, which can be erected for the basement.

- Pile foundation. This type of construction is relevant on heaving soil with high groundwater storage.As for the basement, in this case, the operation of the ground floor does not constitute any problems and fear of any impact on the foundation. The only disadvantage of this method is the particular specificity of the house structure.

- Slab foundation. This type of foundation is suitable for swampy soil with weak soil, as well as with water-saturated sand. With this design, the ground floor will look like a box, on top of which the main part of the house will be built. In conditions of weak soil, slab foundation will prevent subsidence, since the weight of the building will be evenly distributed over the entire surface of the plate.

- Belt foundation. If the soil on your site is not a problem, then this type of foundation is optimal.

The basement width of the basement

The basement width of the ground floor depends entirely on the nature of the walls of the main building. Let's take as an example the frame house. In this case, the width of the foundation can be:

- With a pile foundation - 300-500 mm. Accordingly, the thickness of the walls can be equal to the foundation. At the same time, it is not necessary to build a foundation for the facade, ventilation gap and exterior trim.

- With a monolithic slab, the width of the foundation should correspond to the width of the walls of the basement part of the building.

- With a shallow strip foundation, the width is equal to the walls of the ground floor. But this is the case when there is no concrete screed on the ground floor.

Be sure to think over the places of the holes for arranging the ventilation ducts. They must be indicated on the overall design of the foundation. According to the standards and regulations of the SNiP, they should be from 12 to 24.

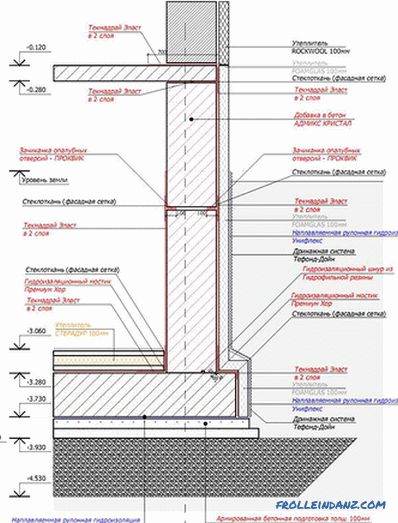

Waterproofing

Waterproofing for the ground floor should be done in 2 layers. The choice of waterproofing material is influenced by several factors:

- wall material;

- climatic conditions;

- soil type, etc.

Waterproofing should cover the entire vertical and horizontal surface of the building. It is also necessary to cover all the points of contact with the ground.

You can use a roofing felt or roofing felt. Such waterproofing will cost you relatively inexpensively. As an option - bitumen mastic. There are no special rules for applying waterproofing. The main thing to carefully protect and cover all areas of the foundation from moisture penetration.

Step-by-step instruction

Below is a detailed instruction of all the actions for the construction of the basement with your own hands. It is necessary to highlight the processes that must be performed:

- Bookmark grounds.

- Fill.

- Waterproofing and insulation.

- Wall cladding.

- Paul.

- Overlap.

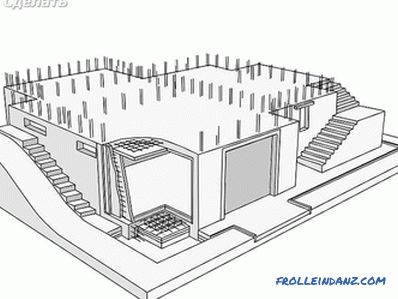

Base laying

- To begin with, the plot is marked according to the building design.

- A pit is digging around the perimeter of the building. The depth is also determined by the project, but it should not be 500-600 mm deeper than the underground part of the foundation.

- From crushed stone and gravel, a fraction of 50 mm is produced, as well as a layer of sand. Each of these layers must be at least 100 mm.

- Each layer is rammed. Sand, in turn, is watered. This will provide better compaction.

- After the tamping, a 5 cm thick base of M100 concrete is poured. This layer is needed to level the base for laying the floor slab of the ground floor. It is also necessary for additional waterproofing.

- When the concrete is completely dry, rolled waterproofing material is laid in 2 layers. It connects with bitumen mastic.

- After the base has been made, you can proceed to the construction of external formwork.

- But first, a floor slab is poured. It will also serve as the basis for the walls of the foundation.

- The formwork can be built from non-removable boards or boards. Formwork necessarily reinforced.

- For reinforcement, buy corrugated Ø10 cm reinforcement. It is connected to each other with wire.

- In places where walls will be erected, reinforcement is additionally mounted in a vertical position.

Filling

- For pouring it is recommended to use concrete M250 or M300.

- The stove is poured with a thickness of 200 mm, and more is possible.

- The flooded solution must be pierced with vibrating rails and a deep vibrator in order for air to escape.

- The surface must be flat. Flooded concrete must be left for 4 weeks.

- In order to speed up the construction process, in parallel, you can begin to build wall forms for the walls.

- Some experts recommend the use of non-removable polypropylene shields, which will simultaneously serve as insulation.

- Reinforcement is also performed in the longitudinal direction of the wall.

- The bars of the reinforcement are tied with the previously installed vertical bars.

- According to the project, leave openings for the doors.And for laying communications, lay the sleeve of a metal pipe.

- You can fill walls with layers or completely. If you decide to pour in layers, then each subsequent must be filled, without waiting for the full drying of the previous one.

In general, the whole structure gains its strength after 28 days.

Waterproofing and insulation

Now it's time to waterproof the basement. You can use a coating or coating material. Inside it is best to use penetrating insulation. It will not violate the steam exchange, as well as increase the strength of the structure.

As for the external thermal insulation, foam polystyrene plates can be used for this. Their fasteners can be done on glue. Part of the wall, which is located above the ground level, in addition, you can use dowels for quick installation. In conclusion, it remains to fill the ground around the perimeter of the building.

If the soil has large and solid elements, it is better to fill it with sand. Otherwise, you can easily damage the insulating and waterproofing layer.

Wall cladding

Sheath external walls are best of all natural stone. This finish is very durable, because this material is different strength. As a result, the wall will be protected from decomposition and sudden changes in temperature. Therefore, you can use marble, limestone or granite.

One of the most modern finishing materials is the socle siding. This plastic is able to cope with the harsh climate, and the sun does not fade. Its installation is carried out on a specially made frame / crate.

As for the interior walls, it is first necessary to decide for what purpose this or that room will be used. Therefore, you will first need to carry out heating and other communications, for example, sewage, water supply and light. Inside the walls are also plastered, insulated with expanded polystyrene, penoplex or foam insulation.

For wall cladding it is better to choose moisture-resistant materials.

Floor

To begin with, the floor is being insulated:

- The first step is to make a sandbag.

- Next, the roofing felt is covered.

- When laying ruberoid, avoid gaps.

- The fittings from the iron lattice are mounted on top.

- Then the floor is filled with concrete M400 or M300.

Depending on the purpose of the room, floor insulation can be performed in different ways. For example, in the living room or gym can be laid on the floor system "warm floor", it can be electric or water. As for domestic premises, it is enough to lay arbolitovye plates or fill the floor with clay expanded with a thickness of up to 100 mm.

A finishing screed made of concrete is poured at the top of the insulation.

Overlap

One of the last stages of construction is the manufacture of floor slabs. There are several technologies here:

- Monolithic concrete goods stove.

- Precast monolithic slab.

- Hardwood floor.

From concrete slabs

From concrete slabs

Consider the installation of a monolithic reinforced concrete slab:

- To begin with, it is necessary to build a formwork with mandatory reinforcement.

- The whole structure is fixed with racks with a pitch of 1 m.

- The slab must fit the walls, 150-200 mm.

- Now you make a reinforcing belt.

- On the walls it should go to 40-60 mm.

- The reinforcement is installed at intervals of 150 mm.

- The next step will be to fill a monolithic slab with a thickness of up to 200 mm.

After pouring, you must wait about one month for the floor to dry.

If we speak of a precast-monolithic slab, in this case the installation of the ceiling is carried out with the help of special equipment. It is important to consider that such overlaps have their own standards, so they may not be suitable for each project. So, for its installation it is necessary to carry out the following work:

- A masonry is constructed along the entire perimeter of the basement to the height of the ceiling.

- After waterproofing is put and poured a small layer of solution.

- At the next stage, steel frames are assembled into which the assembly of a prefabricated monolithic slab will be installed.

- When installed, there will be space between the plates. It must be filled with concrete. The result is a solid design.

Made of wood

Made of wood

Also consider the technology for making wood flooring, it is mainly used for wooden houses:

- Wooden beams are mounted.

- The edges of the beams are wrapped with roofing felt, and then they can be put on the base.

- Pre-made openings for beams in the walls.

- Insulation should be put in these openings.

- After installing the beams, small bars are fastened on the bottom side.

- The reel boards are fastened to them.

- Roll out roofing material and insulation up to 150 mm thick.

By following simple guidelines, you can do all the work yourself step by step. Although in some cases, without the help of qualified professionals and special equipment can not do.

Construction of the basement of concrete blocks

Base of concrete blocks

Base of concrete blocks

If you are in search of an economical option for arranging the basement, then concrete blocks are better suited for the task as nothing. This material is strong enough, well repels moisture, tolerates temperature extremes, resists mold and fungus. If we talk about the shortcomings, then - this is the mandatory use of special equipment for their installation. Manually to cope with them is impossible.

Blocks are installed along the entire perimeter of the future construction. Between themselves fastened with cement. It is imperative to leave indentations between the blocks for conducting communications: water supply, electricity, sewage, ventilation. As for ventilation, the holes should be above the ground level not lower than 150 mm. To prevent debris from entering the holes, it is better to cover them.

If the ground floor rises above ground level, then take care of the space for the windows. In this case, the more windows there are, the better. This will provide zero space with natural light.

In order to avoid having to allocate a lot of money and material for plastering the walls after installation, it is important to install them as smoothly as possible. Although the blocks are durable materials, the top still need to make armopoyas. It is necessary in order to align the entire tier horizontally, since it is still impossible to install it ideally in terms of level.

From foam blocks

The principle of all the preparatory work for installing foam blocks is similar to working with concrete blocks. The foundation is poured with a small thin layer of mortar for laying the first row. To make the material grab better, it is recommended to wet the cement with water. To start is the laying of corners. After the walls are aligned in height and horizontal. Between the corners the fishing line is stretched and the main walls of the basement are pulled out.

After the first row it is necessary to apply waterproofing in a liquid state. Waterproofing is applied in several layers. Each subsequent layer is applied after drying the previous one. After this, the laying of foam blocks continues on a special glue.

Do not forget, each row and the more the angle should be checked for evenness. After finishing the laying, a trench with a depth of up to 50 mm is pulled out along the entire perimeter. In it fit fittings that are welded to the corners between themselves. In conclusion, the trench is poured with concrete. This will happen by reinforcing the whole structure of the basement.

Construction on the slope

Strange as it may sound, the slope only simplifies the manufacture of the basement floor. The ideal slope counts to 9 °. So, there is no need to dig a large pit. Enough of the array cut from the slope. In such cases, the garage in the basement looks original.

If we talk about technology, the first thing to do is airbag and waterproofing. Further construction is described above.

So, from this article it was possible to learn how to properly conduct work on the construction of the basement. If you have personal experience in construction, then leave comments at the end of this article. If you have any questions, you can contact an expert for help.

Video

You can find out how to make a ground floor yourself from the video: