The use of natural materials in the interior of the house is dictated by the desire of people to surround themselves with only high-quality products and products. In recent years, they have become widespread. Such materials include parquet. It is a finishing tile made of wood, made in various versions: single, massive, modular, shield and laminated.

Parquet flooring is a quality product, and with proper care it can have an unlimited warranty period, up to 100 years.

Many novice craftsmen face the question of how to lay parquet. To do this, you should study the basic technology of its installation, as will be discussed below. Basically, the parquet is considered clean from the point of view of ecology and immaculate from external positions material. It is produced from the following natural species: birch, maple, oak, beech, ash, as well as exotic species: merbau, wenge, mahogany. The floor covered with parquet will decorate any interior of the room, delighting with impeccable quality for many years. With proper care, he can have an unlimited warranty, up to 100 years.

A little about the floorboard itself

To answer the question of how to lay parquet correctly, you should refer to its basics, having studied the types of flooring:

Laying the parquet on the screed.

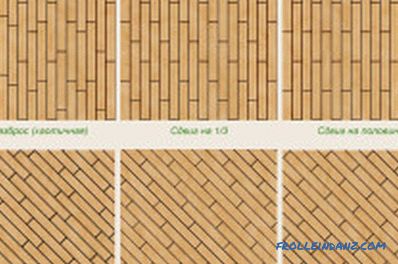

- Piece parquet refers to the most demanded base varieties. It is represented by a large number of planks made from hard wood, connected by ridges and grooves. Typically, the length of such lamellae reaches 500 mm, while their width corresponds to 15-22 mm. Different types of styling are possible here.

- Massive parquet is a variant of parquet, their difference lies only in size and ability to use certain ways of laying. To make this kind of finishing material, you need to spend more wood, so its cost will be slightly higher.

- Laminate is an analogue of a natural base, the price of such material is low.

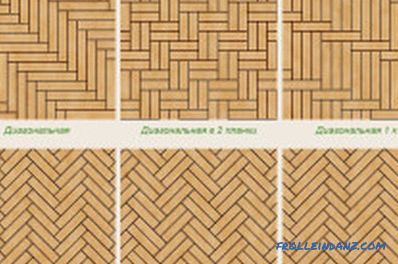

Block parquet is at the peak of popularity. It can be laid in the form of squares, Christmas trees and other variations.

List of necessary tools

Before carrying out the main work, you need to stock up the following devices:

Types of laying of the parquet "herringbone".

- hammer;

- tape measure;

- jigsaw;

- drill;

- wedges;

- saw;

- pencil;

- nails, etc.

The number of inventory often changes, depending on the level of difficulty of the actions performed. So, for a concrete screed, you need a trowel, a plank made of wood, a grinding machine. For large areas, it is advisable to use electric tools.

Preparatory work

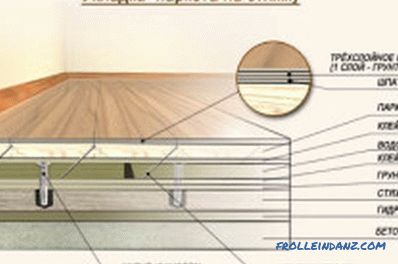

To understand how to lay parquet, it is important to study the properties of the original coating. Starting the laying of this material, you need to take care of the alignment of the plane. She must be flawless. To do this, resort to the use of cement screed or lag coating. The first option refers to one of the sturdiest ways to install parquet.

The screed must be dry, smooth and reliable. Allowable differences will be 2 mm per 2 m of space. Departure from these rules requires the use of a self-leveling base.

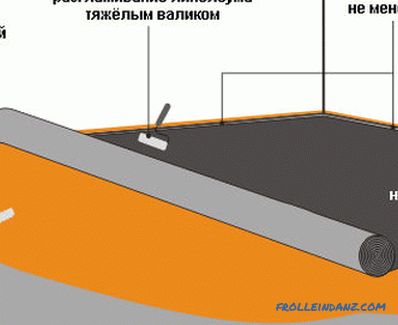

Careless laying of the parquet on the undrilled base will cause damage to the base layer, because moisture will be absorbed by the material. This, in turn, will entail the deformation of the floor surface. For better gluing of the slats, the surface should be primed. It should be understood that the type of adhesive composition must fit the type of primer. The mixture is spread with a spatula or roller.

After that, a plywood sheet is placed on the dried floor. All stacking elements are attached with glue and screws. The parquet should be otlozhatsya in the premise in order to get used to its conditions. Plywood sheets with dimensions of 1.5 * 1.5 m are divided into 4 identical parts. Between these layers should leave a temperature gap of 5 mm, back away from the wall by 15 mm. Slight ground drops are aligned with the grinder. Only irregular joints are processed.

Parquet laying process: recommendations

Types of parquet flooring "deck".

When starting work, it is necessary to determine the type of piling used. Piece parquet is created in order to apply different variants of the location of the slats, the combination of wood of different species, patterns, borders and various inserts. It is recommended to buy material with a reserve, because in the process of laying it may be necessary to have more raw materials than previously thought. It depends on the complexity of the ornament.

To calculate the amount of material used, you can refer to the instructions in the package. The slats are located on the floor very closely, then they are fixed on the plywood with nails, observing a tilt angle of 45 °. The permissible dimensions of possible temperature fluctuations of the base are 1 cm. Once the main installation work has been carried out, do not touch the coating for several days in order to dry the adhesive substance. Composition time is usually indicated on the package.

Next, the parquet is scraped. Surface grinding is usually done 3 times, with each time using special paper of different degrees of grain. So, at first it should be large, then these figures decrease. Each of the layers is processed perpendicular to the previous version.

Surface lacquering is used as a finishing touch.

It is not at all difficult to purchase this type of product. A large number of water-based, consisting of one or more components of paint coatings.

It is necessary to give preference to one or another composition, taking into account the material possibilities and the purpose of using the floor covering. This stage of work is very important; the durability of the structure depends on its proper organization. For starters, it is best to coat the base with a putty, then priming the surface. As a final step, the surface is coated with varnish in several layers. A large number of layers will make the coating attractive from the outside. Any of the applied layers will dry within 24 hours. Often these compounds are replaced by special oils. This is necessary in rooms designed for large crowds of people. These will be public buildings: restaurants, concert halls, clubs, where there are increased loads and a high degree of erasing the floor.

Piece parquet with its practicality for many years remains one of the most popular floor coverings, it is characterized by excellent quality and decent price. Choosing this material, do not forget about regular care for its surface. These measures will help to increase the operational period, retain the foundation in its original form and will delight with its beauty, strength and stability for many decades.

Didn't find the answer in the article? More information on the topic:

-

How to self-level the floor quickly?

How to level the floor quickly? To do this, you must know the styling technology and the sequence of steps. To achieve the desired result, you should know the basic types of base smoothing.

-

How to mount the wall panel

Fastening the wall paneling to the wall: crates. Materials for mounting the frame. Several types of fasteners and how to use them. Photos of individual work moments.

-

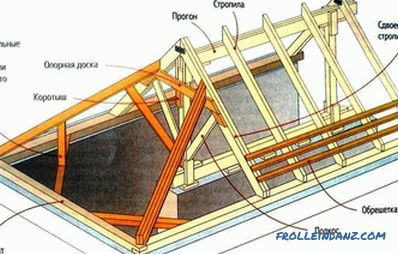

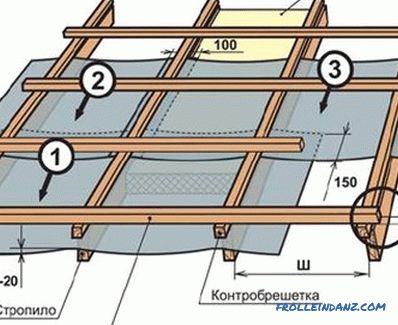

Features of the roof lath

Roof lathing do it yourself: the main varieties of pitched roofs. Creation of a framework for rolled material and under a soft roof. Technology and installation features.