The choice of roofing material does not practically affect the quality parameters of the roof. The main thing when creating a floor is a structure consisting of a batten and a rafter. These parts of the roof are the basis on which the roof is mounted. The service life of this entire complex depends on the quality parameters of the truss system, therefore, during construction, they should be given special attention. In order to properly select the desired construction of roof systems, it is necessary to learn more in detail the principles of their work and their typical components.

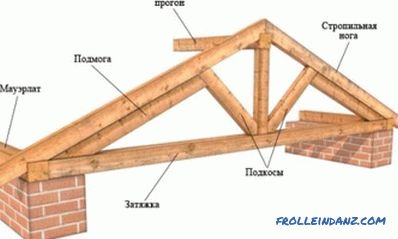

Diagram of the roof truss system.

The structural elements of the roof that transmit the main loads from its weight and various atmospheric influences on the walls of the house or internal supports (if they are in the project) are called rafters. They are made of the following materials:

- wooden beams;

- structural elements of iron or steel;

- combinations of previous materials.

Typically, wood is used in construction. Beam joints are overlapped or end-to-end. For the complete calculation of these elements for bending and torsion, there are special techniques and reference books, with the help of which they determine the dimensions and sections of wooden beams so that the truss structure created meets all building standards and withstands design loads:

Scheme of nasled and hanging trusses.

- winds of varying strength;

- temperature fluctuations during the day at different times of the year;

- precipitation in the form of rain, snow or hail;

- increased humidity;

- icicles icing;

- condensed water vapor - fog;

- invasion of insects feeding on wood (termites, tree beetles) or bacteria causing rotting wood.

Some of these loads are related to roofing, and those that are associated with weight gain (snow) have a direct effect on rafters.

To reduce the effect of snowfall, roofs are made with steep slopes (more than 27 degrees), and the distance between the rafters themselves is reduced.

The influence of the wind on the roof of the house is enormous - when it encounters a building, it creates high and low pressure zones near the walls, and its tearing force is able to tear off part of the roof or blow it up. To minimize these phenomena, the base of the roof should be airtight, and its individual elements have additional attachments to the base.

All materials used in the construction of a house tend to stretch when the temperature rises and to compress when it is lowered. To avoid deforming the roof or its destruction, they should be selected with approximately the same coefficient of thermal expansion.

Layout of roof types.

Water vapor that accumulates inside a building can adversely affect wooden or metal rafters and other structural elements. To partially eliminate this problem, apply special vapor barrier film materials.

To protect against microorganisms or insects, wooden rafters are impregnated with special antiseptic compounds.

Based on the above requirements, in order for the truss system of a building under construction to withstand all loads, the distance between the individual beams is chosen within 0.35-1.1 m.

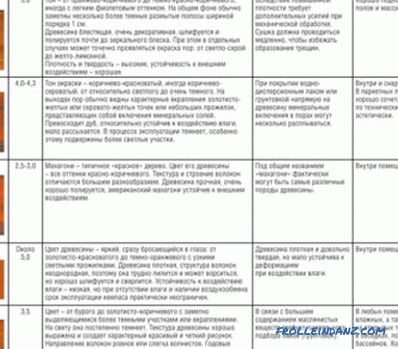

Various types of truss systems

There are the following types of similar structures:

- slanting beams used when the span is covered with a span of up to 15 m;

- hanging truss elements.

Consider both of these constructions in more detail.

The use of overlay truss systems is carried out during the erection of the roof of buildings with a central supporting wall or pillars in the form of the main supporting elements. In this case, the rafter beams rest on the walls of the house, and the middle part of this system - on the supporting wall or pillars.

When using rafter beams for a hanging construction, it is necessary to take into account that they have two reference points located on the walls of the house.

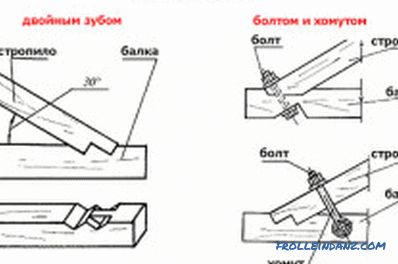

The scheme of fastening the rafters to the power plate.

The rafters of this system are subject to bending and compression, and the horizontal (tearing) force is transmitted to the walls of the building. To reduce it, a so-called wooden or metal tie is made, connecting the roof beams. During the construction of the attic, it is installed near the base, and in other cases it is slightly higher.

It must be remembered that the steeper the slope of the roof, the smaller the distance between the rafters themselves should be. This will reduce the load on the supporting walls of the house during heavy snowfalls.

Basic structures of roofs and their roof systems

The types of roofs used are of the following type:

- single-slope;

- double-slope;

- hip (four-hipped);

- of a different type of half-hinge;

- hip;

- multi-hinged.

Shed roofs are used in the construction of residential buildings is very rare. Mostly they are used in the construction of commercial buildings, terraces, etc. This type of roof is made on walls of different heights. Slope should be located on the windward side of the building. The roof can cover the whole house or be part of a complex roof. In the construction of a shed roof is used on the gutter system.

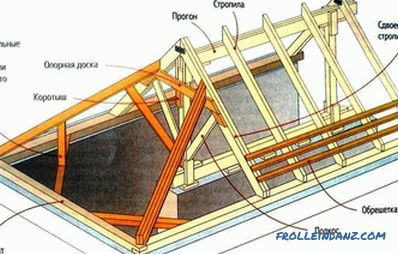

If the size of a country house or cottage is small (for example, 5 x 5 m), then a gable roof overlap is used. Two sloping platforms and 2 gables are formed - this design allows the use of lightweight materials for the roof. It is easy to install, and to create it can be used as an on-wall truss system, and hanging type.

Scheme of types of connection rafters.

If the roof consists of 2 trapezoids and the associated triangular ramps, then it is called hip. This is one of the most difficult types of roofs, which are used in the construction of houses in areas with very high wind loads.

Polycline roofs have many edges and junctions, and under them are usually built attic floors, which makes it necessary to take into account in the construction budget additional costs for their insulation. Rafters in such roofs can be covered with finishing materials or left visible. Mnogochiptsovye designs have the following advantages:

- there is the possibility of overlapping several rooms at once;

- tidy overall appearance of the whole building.

The disadvantage of this design is the increased labor intensity of the work.

The main nodes of truss systems

The selection of the type and elements of the rafters is carried out taking into account the following parameters:

- the desired shape of the roof;

- the overlapped area;

- location and the presence of supporting walls or pillars.

There are a number of standard schemes when designing a gable roof of a building with different distances between supporting walls (pillars):

- If it is less than six meters, then they use the railing system on the slope, which are supported on the mauerlat (cant that goes around the entire perimeter of the house and serves as a support). This design reduces the consumption of materials and labor costs.

- When the gap between the walls is from six to eight meters, the opposing rafters are tied with a crossbar.

- It is possible to use intermediate poles with their support on the supporting wall or pole when using a sliding truss system. This makes it possible to block the span of 13 m, if one support is installed, and up to 15 meters with the use of 2 supporting elements.

- In the absence of internal load-bearing walls or pillars at a distance of more than 12 m, it is necessary to switch to a system with hanging rafters.

The following units are used as elements of such structures:

- supporting parts for fastening roof trusses;

- ridges;

- assembly rows "rack-strut-rack" and "strut elements - rack-beam".

After the final determination with a constructive solution, all the main components of the system are calculated and their plan is made for the construction of a roof of the chosen type.

Production of truss sections and trusses

For them, they use well-dried wooden bars with dimensions that were obtained in the calculation. Of these, right on the construction site, trusses are manufactured according to plan and lifted to the installation site with the help of a crane. When assembling sections of wooden trusses, they can be treated with special compounds.

Finished farms are installed at the calculated distance from each other. When a large area of the roof section is assembled from several raised parts, which simplifies installation.

Approximate list of the necessary materials and tools in the design and manufacture of the truss system:

- wooden bars;

- nails;

- metal supporting and connecting elements;

- antiseptic woodworking compounds;

- crane or winch;

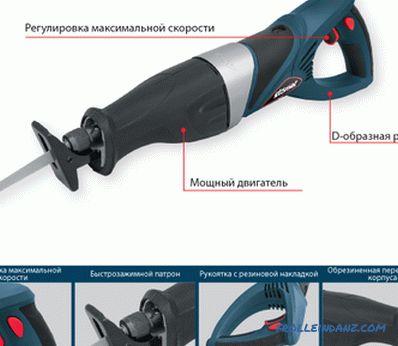

- saws, hammers and measuring tools;

- electric drill with drills;

- roulette;

- reference books for calculating structural units, calculator, pencil.

The correctness and reliability of the functioning of the roof of the erected building and the comfort of the future residents of this house largely depend on how correctly the calculation and manufacture of the truss system is made.

Didn't find the answer in the article? More information on the topic:

-

How to choose the right floorboard

Modern flooring: how to choose yourself. Useful tips and tricks, the main characteristics of the material. Pros and cons, the secrets of the right choice.