When laying paving slabs, you need to know how to install the curb. That he will bring the appearance of the track or platform to the desired state. To achieve this goal it is necessary to follow a few basic steps. About them, as well as manufacturing technology will be discussed in this article.

Types of curbs

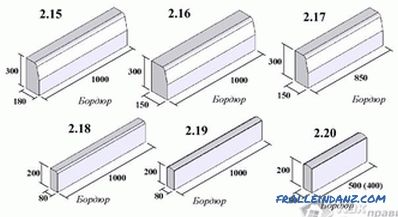

Pavement curbs can have a large number of different configurations. But among them there are two main ones:

- One-sided. It is used in cases when it is necessary to make an edging for the track. In this case, one of the sides is flat, which serves as a stop for the tile being laid.

- Two-way. Very relevant when it is adjoining to the lawn. In this embodiment, the upper end has a beveled chamfer on both sides.

According to the form, the following variants are distinguished:

- semicircular;

- in the wave form;

- in two small steps;

- oblique;

- D-shaped;

- square.

Types of borders

Types of borders

This distinction is relevant only for certain types of materials for manufacturing.

Metal border

Metal border

Metal . This type of product is more like a small fence. The height can be very diverse and is adjusted to the needs and preferences of the customer. Most often it is a tape that rises 15 cm above the surface. In addition, the shape and patterns can also be selected individually. It goes well with any surrounding exterior. Metals that are resistant to oxidation are chosen as the base: aluminum, stainless steel, copper and others.

Plastic

Plastic

Plastic . There are products made entirely of plastic or with various components. The first are more like metal fences. And the latter are made mainly of PET base, which is mixed with concrete. The advantages of this solution is the maximum possible service life. Plastic does not decompose, so no precipitation will not be terrible to him. Especially relevant for garden and park paths.

Wooden

Wooden

Wooden . They are used in the case of a specific project or designer's idea, for example, it can be a country-style garden. In order for it to serve as long as possible, the prepared bars are processed using an antiseptic composition that will prevent rotting. This option is installed much easier than others.

Brick

Brick

Brick . The material can be used bricks of various configurations. The most attractive looks facing. But the choice is important to approach scrupulous and not regret the funds. Otherwise, salt deposits appear over time, which spoil the appearance. The advantage is high maintainability, because to repair the damage it will be enough to replace only one or a few elements.

From a natural stone

From a natural stone

From a natural stone . They are used as whole blocks, which are made by cutting, as well as chips, added to the cement composition. Most often used in the finishing of the tracks in expensive mansions, where it is necessary to create a certain landscape design. In addition, products of this type well protect the installation site from grass germination.

Concrete

Concrete

Concrete . Made by casting or vibrating rammers. The latter are more durable. The advantage is the possibility of self-production. It gives the freedom to choose the shape and color. You can create a unique solution specifically for a specific type of tile.

Why

is needed Give additional strength

is needed Give additional strength

Is it really worth spending your strength to tinker with the manufacture and installation of borders? There are several reasons why they are really needed:

- Give completeness to the whole project. Adjusted contours always look more spectacular than an unlimited path that seems unfinished.

-

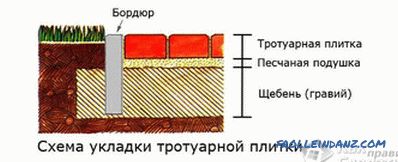

Laying scheme Exclude washing out of tracks. Falling precipitation or approaching moisture can contribute to the destruction of the material laid. Curbs hinder this process.

Laying scheme Exclude washing out of tracks. Falling precipitation or approaching moisture can contribute to the destruction of the material laid. Curbs hinder this process. - Give extra strength. When walking, there is a fairly large pressure on the surface. If you step on the edge, it can easily be damaged. Edge gives extra emphasis, which will avoid this.

- Savings. If we take into account the two previous steps, it becomes clear that the repair of the pavement will be needed less often than in other cases.

- An additional limiter for people with poor eyesight.

- Large-sized curbs impede the arrival of vehicles on the pedestrian part.This contributes to the safety of strolling children.

Give completeness

Give completeness

Such a solution simply does not have any cons, except for the cost of funds and labor.

Independent production

Production of borders can be carried out in two main ways:

- In separate forms. Convenient in that you can make the elements in any convenient place, and then deliver for installation. Such products are easy to repair, as has been described in the case of brick edging.

- According to the place of installation. The fence is poured directly on the desired area. The advantage is the possibility of giving virtually any desired shape.

Mold for the manufacture of concrete curbs

Mold for the manufacture of concrete curbs

There are several solutions in the manufacture of curb modules. The first of them - with the use of U-shaped channel. The process will require:

- a segment of the specified material;

- 2 metal plates;

- metal or fiberglass reinforcement;

- trowel;

- Bulgarian;

- sand;

- cement;

- crushed stone.

Channel

Channel

A territory with a fairly flat surface is selected. This is necessary so that the end product does not have flows. The profile is cut to the required size with a margin of 30 mm. Retreating to 10 mm from each edge, made cuts grinder. Their width should be such that the sheet metal fits in the middle. It will serve as dampers to prevent solution leakage. The inner surface of the channel is polished and cleaned so that it is fairly smooth without rust. In the middle fit a thick plastic film. She must lie with an overlap on the edge, so as not to slip in the process. The next step is preparing a concrete solution. It will be required to observe a ratio of 3: 1: 3 (fine gravel or sifting, cement, sand). It should not be very liquid. A small frame is connected from the reinforcement. Dimensions are selected in such a way that it is completely submerged in the solution. That is, each side should be 3 cm less than the internal space of the channel. The prepared space is filled with concrete. It is well smoothed and compacted. If there is a vibrolath, then it will perfectly help with this. After a few hours, the product is removed, the oilcloth is removed and it is left until it is completely cured.

Self-made mold for the manufacture of borders from concrete

Self-made mold for the manufacture of borders from concrete

You can use an eccentric vibratory compactor grinding machine. To do this, it is necessary to remove the sandpaper, turn it on and walk along the walls of the mold until it shrinks completely.

If there is a desire to obtain a structure of an unusual configuration, then a mold for pouring can be used as a mold. Today they are made of various kinds, so it’s easy to choose one that you like. When choosing, pay attention to the wall thickness. Its size should be as large as possible to support the weight of the concrete. If you did not manage to find something good in strength, then you can make a special stop for the mold. To do this, make a small wooden box or simply dig a hole of the appropriate size. The edges will abut against the walls and will not spread. Fill in the same way as described above. As a reinforcing base, you can use 1 rod fittings Ø12 mm or metal mesh.

There is another interesting way to create a design solution. The form for filling is made. To do this, you can use a channel, sheets of plywood, boards or something else. In the middle of one of the inner corners fit favorite plastic skirting. It is covered with wax from the sprayer to ease the backlog. It can be glued so that it does not move. After that, the prepared cement mixture is poured. After solidification, one or two edges will be obtained with a profile from the installed element.

Installation

Marking for curbs

Marking for curbs

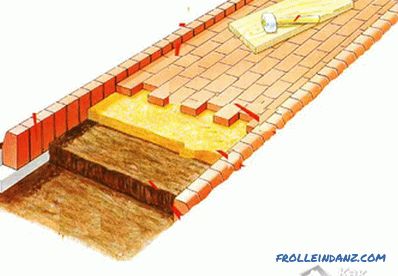

In order to implement fill the border on the spot, you will need to clearly define its location, as well as the planned form. Further, the sequence of actions will be as follows:

- The top layer of fertile soil will be removed along with the roots of the grass and other plants. This will eliminate their proliferation and damage to the structure.

- A trench is being dug. Its depth should be 20 cm plus the distance so that 2/3 of the product is drowned. The width is chosen in such a way as to cover the width of the future formwork.

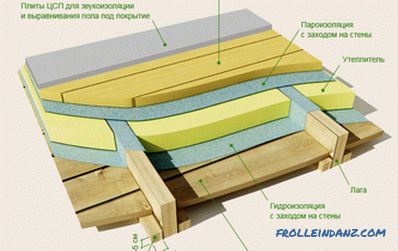

- At the bottom of a layer of 10 cm sand is laid and well rammed. Small crushed stone is filled with the same layer.

- Formwork is made of edged boards, metal sheets or other suitable material. In order to strengthen it on the outer edge, wooden pegs or metal rods are driven in.It is better to try to set it in a level, so that the plane is even.

- A solution is prepared in such ratios as described above. The consistency should not be very liquid, but not dry.

- Metal reinforcement is placed in the trench. It will be enough of several elements placed along.

- The ready mix is poured. She is well rammed. You can use the method with a grinding machine.

- In order to give the top the desired shape, you can make a special molding. For example, for this you can take a wide rectangular trowel and bend around the edges. It turns out the tool with the profile of the letter P. You can add another one. You just need to carry out the butt, removing the excess solution.

- Along the way, iron can be made. To do this, dry cement is applied to the fresh mortar and rubbed. Subsequently get a nice glossy surface.

Full strength will be gained in about a month. If it is too hot outside, then periodically it is necessary to wet the curb so that it does not crack. After a few days, the formwork can be dismantled and covered with cracks in the soil.

Fill the curb in place

Fill the curb in place

The installation of pavement curbs from prefabricated elements is in many ways similar to the previous version, but it has its own characteristics. From the tool you will need:

- pliers for carrying modules;

- shovel and bayonet spade;

- manual tamper;

- tape measure;

- laser plane builder or bubble level;

- geotextile fiber;

- crushed stone;

- sand;

- cement;

- rubber mallet ;

- capacity for solution preparation.

Installation in a prepared trench

Installation in a prepared trench

The trench is prepared according to the steps described above . But between a layer of sand and rubble is laid geotextiles. It will give extra rigidity.

- Pegs are driven in along the entire length of the planned work. They can be from any suitable material. Between them the fishing line or string is pulled. It is aligned with a laser plotter of planes or level. Its height should be a label for the top edge of the border.

- A cement-sand mixture is prepared in proportions, as in the previous case, but no crushed stone is required.

- It is laid out evenly on the prepared base on the size of the border element. The thickness should be from 3 to 5 cm, it all depends on the specific conditions.

- With the help of a bubble level and a rubber mallet, focusing on the tensioned cord, alignment is performed.

- The joints between the blocks are coated with cement-sand mixture.

- To increase the strength of the whole structure, the base can be poured another 5 cm.

- After the concrete grabs, it can be filled with sand and compacted.

- It is better to start laying tiles only in a day.

Installation of curbs

Installation of curbs

Installation of a curb from a brick is carried out in exactly the same way. But a trench for it will require less depth. There is also no sense in too large a layer of the solution, 1 cm will be enough. With regard to metal products, it will be sufficient to prepare pits for the legs of each section, if they are provided. Make them large by 10 cm on each side. The inner walls are covered with roofing material or other waterproofing. The bottom is compacted in the same manner as described for trenches. Modules are installed and set by level. The solution is poured. Prior to its setting, additional struts can be made to prevent the fence from moving from its place.

Border tape

Border tape

In the case when it is necessary to divide the space into zones, then optional to install curb. In this case, a special tape may be useful. It is made of polymeric materials. Often its thickness can be 2 mm, and height up to 30 cm. In order to install it, you will need another assistant. A narrow trench is dug around the perimeter of a particular plot. The tape is well stretched with an emphasis on one of the walls. After that, it is filled with soil and well rammed.

Now you have a basic knowledge of how to properly make and install a sidewalk curb. Each project turns out individual. We would be interested to know what happened in your case. Share your impressions and tips in the comments to this article.

Video

Finished curbs are set as follows:

If you decide to fill the curbs with concrete in place, you can act like this: