The so-called cable channels, widely used for laying various types of electrical wiring, are currently in great demand among wiring specialists. Cable channels reliably protect the laid lines from any mechanical effects and have the following advantages:

- ease of installation, disassembly and maintenance of wiring, laid in cable channels;

- low cost of products, as well as simplicity their fastening;

- high performance of cable channels made on the basis of composite materials and possessing in this connection increased resistance to fire.

In this article we will talk about how to fix the cable channel to the wall of concrete or drywall.

Preparation for installation

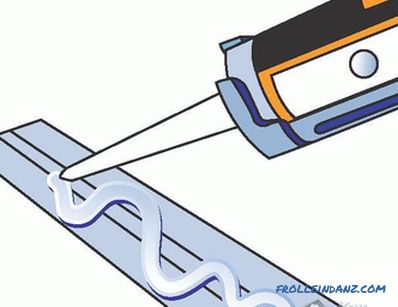

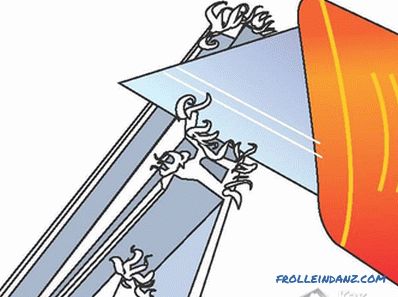

Applying glue

Applying glue

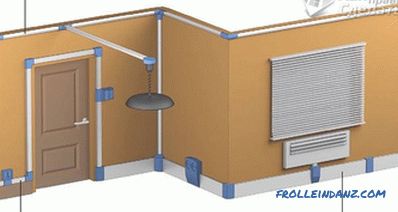

Before you attach the cable , cable, you need to carefully consider the layout of the route, taking into account possible descents, ascents and turns of the laid lines.

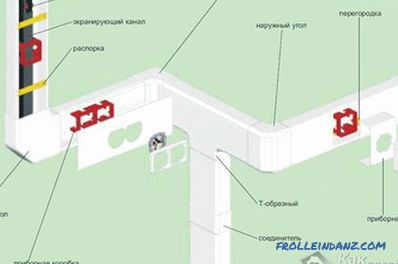

Properly carried out marking will allow you to choose the right size of the cable channel and decide on a set of all the necessary accessories (T-shaped joints, various angles, connectors, plugs, etc.).

Fastening the cable channel The choice of fasteners used for mounting the base of the channel cable is usually determined by the base material (surface) on which it is fixed . Most often, cable channels are laid on the following surfaces:

Fastening the cable channel The choice of fasteners used for mounting the base of the channel cable is usually determined by the base material (surface) on which it is fixed . Most often, cable channels are laid on the following surfaces:

- wooden walls or walls;

- plasterboard surfaces;

- brick walls and partitions;

- concrete bases (walls or ceilings);

- metal surfaces.

For wood surfaces, self-tapping screws on wood will be the most suitable, while special dowels-nails with a diameter of about 6-8 mm are suitable for concrete and brick foundations.

For attaching to plasterboard surfaces, you can use standard wood screws. In the case of a significant total weight of the wiring laid in the channels, it will be safer to use the "butterfly" dowels (it is allowed to alternate them with wood screws). A sufficiently secure attachment is presented in this situation and dowels of the type "screwed".

The choice of fasteners for metal depends on the thickness of the base; at the same time, standard self-tapping screws for metal profiles are suitable for mounting on coatings up to 2 mm thick. Very often used in this case, and such a common type of attachment, as screws - "bugs".

Useful tips

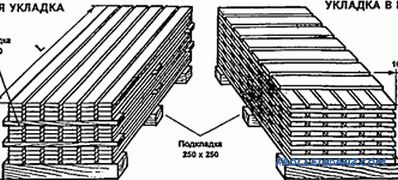

Fit sizes

Fit sizes

When choosing a step that should to install fasteners, it should be assumed that the more often they are located - the better. But it is also not recommended too often. Note that installing them in increments of 40-50 cm will provide  By gluing the backrest you will have sufficient reliability of fastening the base of the channel cable.

By gluing the backrest you will have sufficient reliability of fastening the base of the channel cable.

An increase in the density of fasteners (step reduction) is necessary in cases where the wall surfaces in the room have noticeable irregularities. In such situations (in order to avoid the formation of a large gap between the surface and the base of the channel), the gaps between fasteners should be reduced depending on the circumstances.

It goes without saying that in case of a significant increase in this distance, the possible load on each fastening element increases, which negatively affects the reliability of the whole structure as a whole.

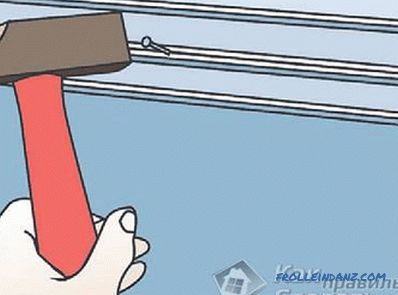

Mounting the upper part

Mounting the upper part

It is also worth noting the following: the channel must be fastened with an eye to the aesthetic side process, it does not hurt to take advantage of the construction level, with the help of which you will be able to align the laying of the bases, thereby increasing the aesthetics of the installation.

Video

How to choose a quality cable channel, tell the following video:

The following video presents the process of assembling a cable channel:

Photo

Hard floor cable channel

Hard floor cable channel

The final version

The final version

Floor

Floor

Installation of open type electrical wiring

Installation of open type electrical wiring

Metal cable channel

Metal cable channel

Flexible floor cable

Flexible floor cable

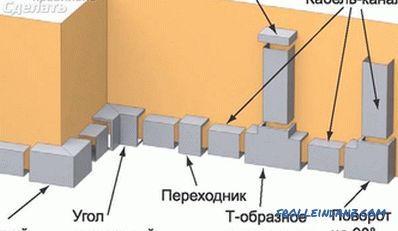

Additional elements of the cable channel

Additional elements of the cable channel