Often it takes a lot of time to build a house. At this time, lumber needs to be stored somewhere. If you leave it just under the open sky, then over time the wood will become unusable and lose its original color and properties. Lumber storage conditions should be created suitable for long-term preservation. It is best to keep boards in stock, but this is not always the case.

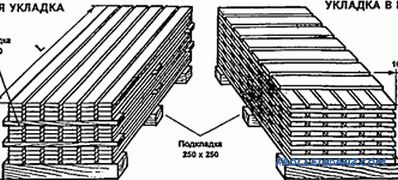

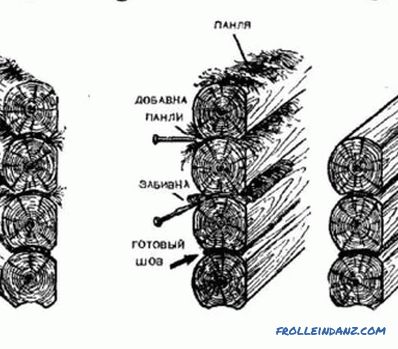

In-line laying and laying in cages of sawn timber.

In some cases, you have to navigate the terrain and create awnings. Here, too, all conditions must be created for storing lumber. Storage should be carried out in accordance with all rules and regulations. So, consider how lumber is stored.

Storage: nuances

The best place for long-term storage of lumber and wood is a warehouse. The rules for storing lumber in stock are specified by the relevant rules, which are described in the system of state standards. It should be carried out in warehouses that are equipped on elevated terrain. Here air must constantly circulate so that the wood can be easily ventilated.

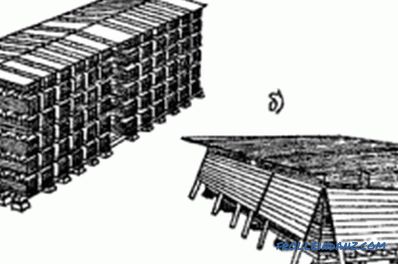

Laying patterns for storing edged sawn timber: a - a stack with a gable roof; b - a stack with a single sloping roof and shielding walls of moisture protection.

When organizing such premises, a slope must be organized. This will facilitate the removal of rainwater. In this case, the facility must necessarily be located not less than 50 m from residential buildings. If there are potential sources of lumber infection nearby, then you should also stay away from them. Warehouse settled at least 100 m from those.

Often the storage room is divided into several main sections:

- unloading area;

- lumber storage area;

- sawing area;

- the place where the waste will take place;

- the place for recycling.

All these areas should be fenced from each other. For carrying out loading and loading works, it is necessary to equip a special platform type platform. The floor in it must be made of wood. It must be pre-dried and covered with a special antiseptic solution. Sometimes it is not possible to equip the platform type platform. In this case, it is worth thinking about how to make it out of asphalt. It should be located slightly above the floor of the warehouse. In this case, it is also necessary to lay wooden bars, pre-treated with an antiseptic.

Storage of lumber out of stock

Proper storage of wood.

Sometimes such situations arise when the warehouse is simply impossible to organize for one reason or another. Be sure to think about how best to store lumber in the open air. Open and closed awnings can be arranged. About them and it is worth talking in more detail.

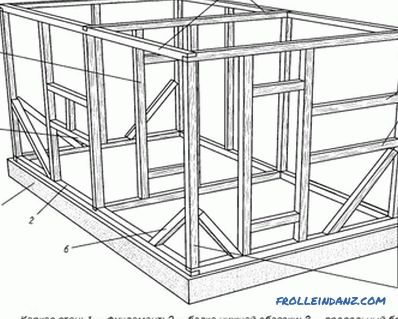

Open canopies should always be located along the direction of the prevailing winds in this area. They are mainly used for storing lumber only in the summer. Here you can arrange the wood, which is checking the physical properties.

Closed canopies are located across the prevailing winds. They are made with collapsible walls and can serve for sufficiently long storage of wood. The soil, located under the canopy, must be asphalted or concreted. On its sides canopies are installed under the piles. It is necessary to organize the passage of a width of approximately 3 m for the smooth movement of loading equipment.

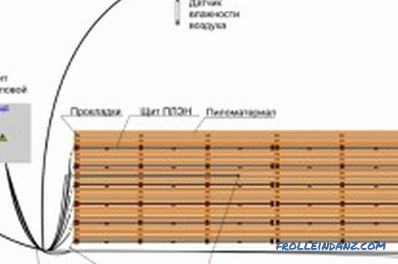

Drying lumber with your own hands.

The walls of such a structure must necessarily protect the timber from the effects of ultraviolet rays and moisture. They must also allow the wood to breathe, that is, be ventilated. The bases for the sheds of both types must be stone. All wood used in their construction must be healthy.

It needs to be treated with an antiseptic. Otherwise, it may form a mold or fungus, which will adversely affect all the wood under the canopy. The roof is preferably made of metal.

Sanitary measures

In order for wood and lumber to be stored for a long time in a warehouse or under a shed, various sanitary measures should be taken, which should not be limited to cleaning the room from dirt.

From the area where the lumber is located, be sure to remove dust, splinters and dirt.

Such a measure is a necessity, it is a fire safety technique.

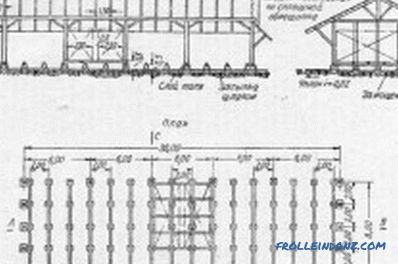

The shelter canopy for storing open sawn timber.

In the summer period, the warehouse area should be treated with a solution of salt or a weak solution of sulfuric acid. This measure will help protect the area from grass growth. In winter, it is imperative to clean the area and roof of a shed or warehouse from excess snow.

Periodically, a visual inspection of all parts of the warehouse, as well as lumber, should be carried out. Over time, various microscopic abnormalities that can lead to the development of diseases can form on them. All damaged lumber must be removed from the storage area. They are moved to the place where the marriage is stored, or sent immediately for disposal.

The Fire Inspection never disregards such objects. It prescribes the rules of fire safety, which must be observed at the facility. Timber is very flammable, so its storage should be treated as carefully as possible. Fire safety prescribes the installation of various fire extinguishing agents in the warehouse, which, if necessary, should be used for its intended purpose.

Additional Information

Properly storing material is very important. After he arrives at the warehouse, it must be unloaded. At the same time it fits on special lining bars. It protects the boards and wood from various harmful effects. Laying lumber on the ground is strictly prohibited. If it comes in different cars or cars, then it is also not recommended to mix wood. All sawn timber that has been deposited must be transferred within 2 days from the time of unloading directly under the shed or into the warehouse. In winter, in rare cases, the cleaning time can be extended to 3 days.

Next, the lumber is stacked for storage on piles. The distance between them should be such that a person can move without any problems. The contact of sawn timber located on adjacent piles is not allowed.

This is how modern lumber is stored. It is very important to follow all the recommendations given above. This applies to the organization and storage facilities, and canopies for storing wood. Otherwise, there may be an unpleasant situation associated with its rotting, which will lead to loss of material. This entails additional construction costs, which is unacceptable.

Didn't find the answer in the article? More information on the topic:

-

Tools for caulking the house from a bar

A caulking iron from a timber house protects it from external influences. For caulking iron, felt, moss, jute, hemp and tow are used. Plugging the gaps between the logs can be 2 ways: stretching or in the set.

-

How is wood waxing done?

Step by step instructions on how to wax wood. Useful tips and tricks, materials and tools for work. How to prepare the surface? How to apply wax properly?

-

The better to treat wood from moisture

How to process wood from moisture. Useful tips and tricks, basic characteristics of impregnations and materials, design features, nuances. Advantages and disadvantages of impregnation.