Today there is a great interest in the construction of wooden houses, including according to the old technology of log. This is due to the desire of people to live in an environmentally friendly home.

Log houses are popular for their environmental friendliness.

Meanwhile, to satisfy such a desire, we have to remember the architectural and construction secrets of the ancestors. There are quite a few of these secrets, and one of them is knowing how to chop a log building into a bowl.

In practice, there is nothing particularly difficult in mastering this technique, although carelessness and self-reliance are unacceptable here. It is necessary to thoroughly understand some subtleties and understand what a log house is in a bowl and what it is good for.

Cutting a felling into a bowl: its pros and cons

This way of building skeletons of buildings brought to the present the spirit of an old Russian dwelling that is reliable, captivating with its folk-style. In this technology, the connection of times is very tangible, and today builders who know how to chop a log cabin, just like their colleagues hundreds of years ago, are actively building houses for permanent residence in this way and the Russian baths loved by the people.

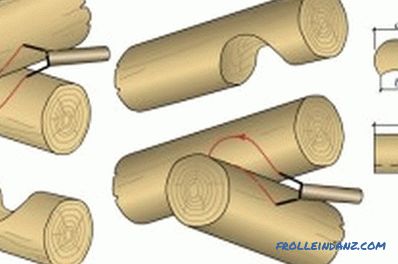

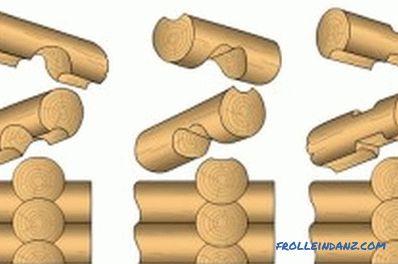

When a log house is laid in the bowl, each upper log is placed in a semicircular recess, which is cut in the lower log perpendicularly.

The essence of such an angular joint of processed logs is that each upper log fits into a special semicircular recess cut in the lower perpendicular log. A notch, which is called a bowl, is made of such size that the upper log, after being laid, lay tightly enough on the previous log of this wall. Thus, a continuous, without significant gaps, vertical overlap is created.

The age-old experience of folk construction and climatic features in a particular area have had a definite influence on the development of this technology. The variant of the angular bundle of logs, when the upper log falls into the bowl, is called the "Russian felling" (or "flush"). But there is a reverse way of how to cut a log house. It consists in the fact that the cup is cut down in the upper log on its lower part and therefore falls on the lower log. This technique was called the "Siberian cutting (or" okhlop ").

The emergence of this technology was due to more problems with cold and precipitation in Siberia compared to the middle zone of Russia. Many experts believe that the Siberian variant felling reliably protects the log house from penetrating moisture and frost.

Choosing the option to chop the log house in a “bowl” method, the master assumes some responsibility for the result.

Grace Next to this connection, the construction of a log building is very strong, with warm corners, not blown by the wind.

Marking and logging "into the bowl".

A beautiful original house, created by environmentally friendly building materials, looks very harmonious and does not require additional exterior walls.

At the same time, the customer may experience difficulties if he nevertheless decides to sheath the frame. This is a minus of this technology. Another disadvantage of a log in a bowl is a rather large consumption of material compared with other log-cutting technologies. Due to the protruding 50-60 cm of corners, the builders lose the useful living space of the house.

How to cut a log house into a bowl: materials and tools

For comfortable and productive cutting of bowls you will need the following tools:

- carpenter ax;

- chainsaw (electric saw);

- chisel;

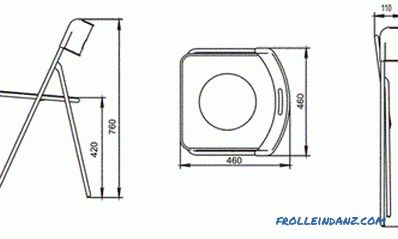

- carpenter's compass (carpenter's line);

- insulation (tow, moss, jute, etc.).

What kind of wood is better to use for the construction of the log?

In order to successfully cut the log into the bowl, there is little good tool and the corresponding skill of the builder-carpenter. It is necessary to decide on the best material for this, which will resist infection by fungus and attacks of bark beetles

Types of cut-in "into the olop".

Carpenters recognize pine as the almost ideal breed of wood for this. It is valued for a smooth, almost knotless trunk, characterized by a high degree of hardness. At the same time, this circumstance does not at all interfere with the convenient processing of which pine differs. On the other hand, as an integral element of the building wall, it impresses with its reliability and durability, good resistance to decay and the absence of cracking as a result of drying.

To chop a log house confidently and fairly quickly, it is recommended to pick logs of approximately the same length and diameter. At the same time, the most practical diameter in terms of experience with this technology is 22-24 cm.

As for the logging time for a future log house, experts advise doing this in the winter. It was at this time in the trunk of the tree contains the least juice.Therefore, during the subsequent drying of winter wood, it will be minimally warped; destructive cracks will appear in the trunk.

How to cut a log house: a sequence of operations

A good breed of wood for building a house from a log house is pine.

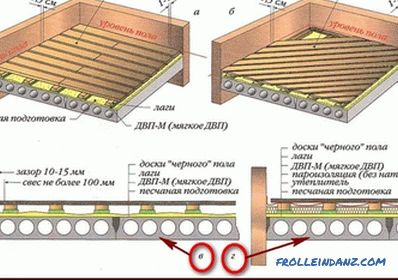

The production of any log house, including the "in the bowl" method, begins with the preparation of the site on which the house will be built. By the beginning of the installation of the first, lowest layer of logs, the foundation of the future structure should be mounted in such a way that the starting salary is strictly horizontal. Before starting to build walls, be sure to put a layer of waterproofing material on the foundation.

The setting of the finishing rim begins with the installation of two logs parallel to each other, which will later become part of the long walls of the future building. Between them there should be a distance equal to the length of the planned log-cross member.

After the first logs take their strictly horizontal and parallel position, 2 perpendicular logs are placed on their edges. Using the crossbars laid out in such a way, the marking of future recesses-bowls is made. This operation is carried out with the help of a carpenter line.

The Contractor should very carefully note the semicircles on both logs at the same time, since only perfect accuracy of calculations and markings ensures the maximum fit of the logs to each other. At the same time, the depth of hauling of the bowl should guarantee that the upper log in the lower one will fit so that the upper barrel protrudes from the lower one to half its diameter.

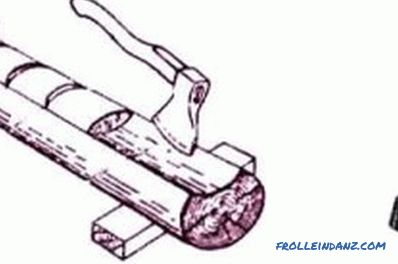

The markup is followed by the sample itself. It is produced by a chainsaw, an ax and a chisel. After removing the wood from the bowl, make a trial installation of the logs for a tight fit to each other.

To create a tight fit of the logs in the vertical plane, a special groove is cut at the upper edge of the lower logs.

To create the most tight fit of the logs to each other in a vertical plane, a special groove for compaction is cut down on the upper edge of the lower logs along their entire length. Its thickness is influenced by the size of the logs, as well as the climate that prevails in the area where the building will stand. It usually ranges from 120 mm to 200 mm.

In the ideally selected sealing grooves there should be no slots. Nevertheless, despite this technological requirement, for additional thermal insulation, before installing each upper log, the groove of the lower log is laid with insulation.

When installing logs in bowls, they are leveled using special dowel pins, for which they pre-drill holes in blanks to a depth equal to the height of one and a half logs. Putting logs in this way, they are tapped with a wooden chock. And all this time it is necessary to follow the strict vertical walls.

Work nuances

In order to cut down a log house and to make it resistant to bad weather, the logs are oriented with thin annual rings to the street and thick rings to the inside of the future home.

To facilitate this process, you can build a building in parts. The relays (as these parts are called) are usually tied up on the ground, lining up by the size of human growth. Then each of them is dismantled and re-installed on the base frame.

A pile option is the optimal choice for the foundation for a wooden blockhouse. It is easy and quite simple to install.

In the absence of the necessary experience, it is recommended to start the production of log cabins with the construction of something small and not very significant, for example, from a garden gazebo or a small bath. So experience will come and the skill necessary for building a full-fledged house will develop.

Gradually having learned the construction wisdom, the master will be able to create something not only habitable, but also causing enthusiastic responses with his exquisite appearance.