A diverse work tool is used at work or at home. Therefore, how to choose a circular saw can be equally thought of as the head of the meat processing shop, as well as a simple carpenter, who needs it for cutting wood in living conditions.

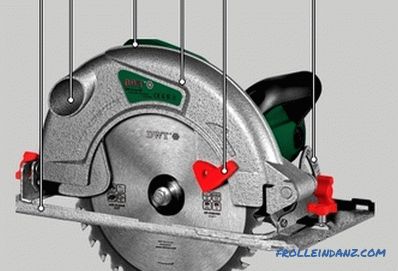

Circular saw device: 1 - base, 2 - branch pipe for removal of sawdust, 3 - switch, 4 - protective casing, 5 - protective casing, movable, 6 - scale angle of the hull.

This fact primarily means that the saw can be completely different in its methods of fastening, use and is designed to work with a very wide range of materials:

- stationary;

- portable;

- manual.

There is no doubt that the reader knows that the circular saw is a circular disc with a certain number of teeth. Everything else to which this saw is attached, can be called a device that facilitates and ensures the work of a circular saw. Therefore, intending to choose a circular saw, a person decides which method of using this tool is more to his liking.

Regardless of the purpose and scope of future use

Realizing the need to have your own circular saw and knowing almost nothing about this equipment, you should start inspecting the saws from their appearance. He can say the following:

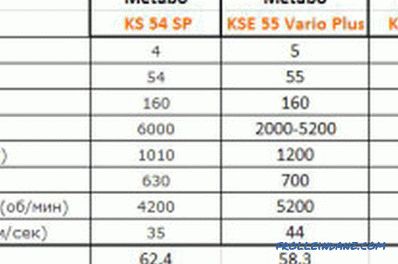

Comparative table of the most used circular saws.

- working surface of the saw, its width and material;

- reliability of fixation of the working surface and other parts;

- engine power;

- the convenience of fixing the saw blade itself, the possibility of mobile replacement.

Next, by taking a circular saw in your hands, you can roughly determine its weight and convenience of this design, taking into account individual needs. For example, a saw that weighs less than 8 kg will hardly cope with a large amount of work.

Sometimes you should trust your intuition, if you don't like the device you took in advance and something seems to be not quite convenient in it, it is better to continue to look for another model.

Degrees of protection and cost

As already noted, circular saws can be used for various types of materials. Most often it is wood. The circular saw can make longitudinal, transverse cuts. But saws can be used for cutting plastic, metal-plastic and even have a saw for cutting on metal.

For all types of materials there are the following disc differences:

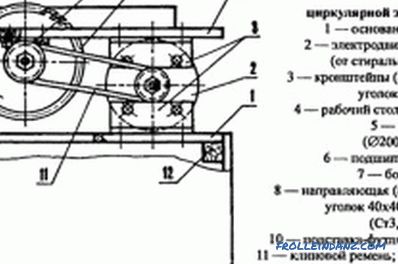

Circuit layout of a circular electric saw.

- disk diameter;

- the shape of the teeth, their distribution on the disk;

- the number of teeth.

The saw blades are made of high-alloyed or carbon steel, the teeth of the last representative are made of tungsten or carbide. Moreover, there are no universal disks. They differ even for one material, within the framework of what sawing is performed: longitudinal or transverse. For example, for cutting materials across, use a special sharpening, which implies the presence of a negative angle of grinding.

When choosing a circular saw, it is necessary to pay attention to the security measures taken by the manufacturer when creating his model. It can be anything: a button that protects against accidental activation, all kinds of frames and attachments that limit the likelihood of injury. The degrees of protection in modern saws can be attributed to electronic devices, which clearly control the operation of the device and ensure that it turns off if the saw is clogged. This will protect the user not only from a possible reverse shock wave, but also the engine from overheating and its failure.

The profiles of the saw teeth.

With all this in mind, when buying a circular saw, paying attention to all of these advantages or, on the contrary, disadvantages, you should not chase after an expensive product. Perhaps, for work in the country, in the house, for small household repairs there will be enough saws for working with lightweight materials. This will significantly help to save the family budget.

In this case, an expensive high power saw is not practical. But to pay attention to the work surface, guide rails, fasteners of equipment elements is necessary. To control the safety of work, you can begin with the purchase.

Technical Information

Engine power is very important. That it will provide the rotation of the disk. Therefore, attention should be paid to the correspondence of these values. Weak engine will be very difficult to give the required number of revolutions of the disk for a certain unit of time. Slow disk appeal will slow down the work, and this is at best, at worst - such a saw simply cannot cut thicker and more durable types of wood.

In this regard, there are saws designed for cutting materials of various thicknesses and strengths.

According to the level of professionalism and power required for the device, there are:

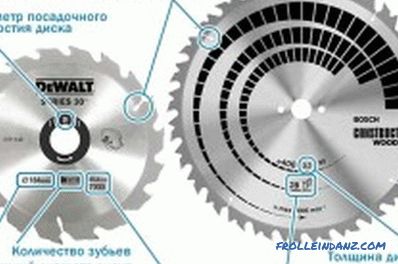

Information placed on the saw blade of the circular saw.

- sawing light materials (up to 800W);

- universal sawing (from 800 to 1200 W);

- professional sawing (more than 1200, the required voltage 2. 2 kW).

The voltage required is not that great.

It is very good if there is a set of additional discs of various diameters in the saw set. By changing them using the same power, you can achieve the ability to cut materials of different thicknesses. Before buying it is worth knowing how easily you can buy spare disks for this model. In fact, this process is not easy. The discs can differ not only in the presence of teeth on the edge of the circle and their diameter, but also in the depth of fit. Sometimes it is very difficult to choose the desired configuration. In some stores, adapters are available that allow the use of "non-native" saw blades. Consider disc marking. The use of materials of inappropriate physical parameters may result in equipment damage.

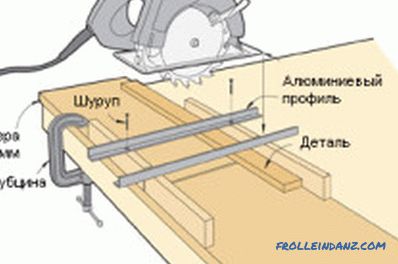

Special tools for securing the circular saw allow you to get a stationary mini-machine, which is very convenient to work.

In addition, there are submersible saws that allow you to start and end the sawing process at any point of the selected object. Sometimes it is necessary not to cut the board into several parts, but to make notches in it. Sometimes it is necessary to make a cut only at the beginning or end of the product. Skilled craftsmen can use for such purposes and ordinary saws.

Usually, the accompanying passport indicates the number of rotations at idle. The faster the saw, the smoother and flawless the cut will be. It already speaks about high quality of the produced goods.

This information is appended with thicknesses that can be cut with a specific instrument. Sawing at an angle of 90 degrees and 45. There are no special tricks. And if the equipment is working properly, then there is no reason to doubt the veracity of the attached facts.

Tabletop circular saw

Such a saw can be classified as stationary saws. It has the same technical varieties as the hand saw. With proper sharpening of the discs, by varying the power and selecting the right diameter of the circular plates, you can cut wood, glass materials, metal, plastic, and drywall on a table saw — almost everything except concrete.

Table for a circular saw.

It is almost always ready to work, it saves time for the employee to adapt and get used to the device. Accelerates sawing standard plates, putting it almost on the stream. Also guarantees even more compliance with standards of safe labor.

When choosing a table saw, one should be guided by almost the same principles as for the manual version of the product. But to them is added the area of the table and even stricter control on the choice of saw blades. Here the most important additional functions, because there is no manual adjustment of the cutting. When the price difference pays off very quickly, it will be a shame that you have to work on equipment with worse capabilities.

Useful devices and functions

Modern saws have a lot of advantages over their predecessors, today it is useful to have some improvements on your circular saw regardless of the method and place of use:

- brush wear indicator;

- dust and sawdust cleaning system;

- removable electric drive or battery engine;

- laser pickup for sawing line.

It may be that for some people these features will seem superfluous, but still they simplify the work with the device, make it guaranteed in terms of equipment safety, and also relieve you of contacting service centers for small things, for example such as damage to the power cable.

If you look at the table of the most frequent breakdowns in circulars, the wear of the brushes is almost the most common defect that can be foreseen while watching a special indicator.

To improve the quality of work performed and to reduce time costs, it is very convenient to use a laser pointer of the cutting line. I must say that some craftsmen who bought cheaper models came up with very interesting devices that help to get an even cut. Those interested can take an interest and look for comparative video lessons for different saws that do not have a laser tag.

Many saws have a system that prevents the disk from starting abruptly, which will protect the engine from sudden voltage surges at the start of work.

Each person decides for himself whether he needs these innovations, because each visible and tangible advantage makes the price of the device higher.From the example it is clear that ingenuity and skill can do without many innovations. Sometimes the allowable cost of expensive equipment can be explained by the savings, depending on the speed and quality of work.