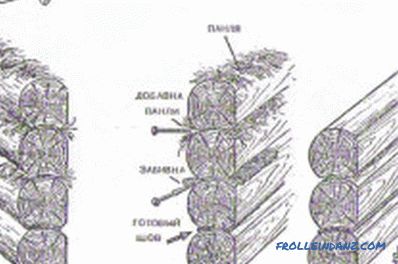

To caulk a log house, like a log house, is required without fail. And this should be done regardless of the circumstances of whether or not the interior and exterior are made with insulation. But what materials can be used for this, now and find out.

The scheme of warming a house from a bar with jute.

Requirements for a contouring material

In a generalized form, all the material with which it is possible to caulk a house must meet the following requirements: level;

Varieties of caulking material suitable for timber

Scheme of home insulation from timber with tow.

Wood has been used in the construction of houses for thousands of years; therefore, our ancestors gained considerable experience in caulking and using materials.

Moss and today remains the best material for caulking wooden log cabins. But not any moss is suitable for these purposes. For caulking, sphagnum moss is used, which grows in swamps and has a red, light or brown tint. Subsequently, peat deposits are formed during its rotting. Even modern materials are inferior in their qualities of durability and ecological moss. Proof of this are old abandoned wooden huts in villages where the log itself has already rotted and the moss is in excellent condition.

As an inter-spring sealant, moss is an indispensable material due to its antibacterial, antiseptic and healing properties. Squeezed between the bar, it prevents the development of putrefactive bacteria and mold fungi. Due to this, the tree retains its qualities longer and prolongs the period of service. Freely flowing through the air, moss imbues it with healing vapors, therefore, the internal atmosphere of the house turns into a healing one. The hygroscopicity of moss allows to level the drops in humidity. The properties of moss do not allow to detect any flaws in this material. But the "minus" lies in the other - it is not very easy to deal with mossing moss, otherwise there would be no other materials for these purposes.

A flax tow is used as a sealant and sealant everywhere, and as a caddy material - more often in those regions where it grows and where there are no marshes that allow moss to be harvested.

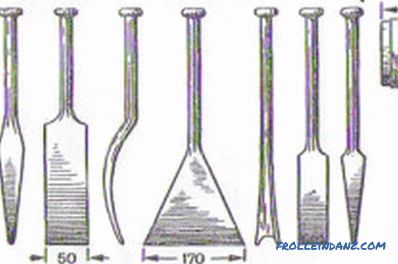

Wall caulking tools.

There is no production of flax tow. It is produced by vystruski and towing when cleaning flax fibers. It is also formed as waste from the manufacture of ropes, linens, ropes. Like moss, but to a lesser extent, flax towers are endowed with bactericidal and antiseptic qualities. That is why they treat tow in order to increase resistance to moisture with resins. If natural tree resins are used for processing, then tow is still considered an environmentally friendly material. But if it is impregnated with oil products, here it is not possible to speak about any naturalness and harmlessness. Tow consists of a large number of fires, shaken out during the first years since the operation of the house. Because caulk tow not once, but several.

Hemp hemp is very similar to flax tow, with one exception - its fibers are coarser, so this kind of caulking is often confused.

Hemp is not afraid of temperature fluctuations and high humidity, so it is advisable to apply it in regions with high humidity. These characteristics of hemp are obliged to polymer lignin, which is present in any kind of wood, bonding cellulose fibers. Hemp is able to maintain its qualities, even when wetted, so she does not face rot.

Modern materials for caulking

Jute comes to us as an import from abroad (China, Egypt, India and other tropical countries with abundant precipitation). Jute is produced from shoots of the same name plant of the Malvaceae family. Jute fiber is quite durable, it is not susceptible to mold, putrefactive bacteria, birds and insects are not interested in them, it is hygroscopic (easily accumulates moisture and gives up) and high throughput for air masses. There is lignin in jute in the same quantity as in the tree. The similarity of properties with wood makes them perfectly compatible materials.

Jute can also be represented by fiber, and maybe even tape.

The latter have different widths. Jute insulation in the form of a tape is convenient in laying between the crowns of the house from a bar. Clean jute makes it possible to compact it evenly. Both the quality of the material and its cost are at the same high level.

Along with fiber materials for insulation we use felt types of it (mezhventsovy felt):

- Jute. Its composition: 90% - jute, 10% - flax. But it is better to make sure of the accuracy of this ratio, since such can be encountered: 70% jute, 30% flax.

- Linen (has other names - Eurolyn, flaxvatin). This needle-punched matter, consisting of flax with a high degree of purification.

- Lnodzhutovy. The ratio of jute and flax - 1: 1.

Modern heaters, made exclusively of flax, are considered the best option for caulking, because their interaction with wood is the most optimal, which also ensures shrinkage uniformity. Other materials with flax additives in a particular ratio only worsen the characteristics of the insulation. Properties become worse, the greater the percentage of flax.

A few words about caulking

A house from a bar is caulked in several passes. This need is explained by the fact that the drying of the timber occurs gradually, while the house shrinks due to its own weight. The shrinkage is most pronounced in the first year and a half after building the house, and then it decreases every year. Experts note that 5-6 years is the maximum period when shrinkage is possible. Therefore, caulk construction 3 times: during the construction period, at the end of the 1st and 6th year.

Didn't find the answer in the article? More information on the topic:

-

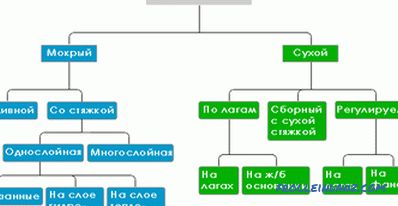

Processing of wooden floors

Processing of wooden floors: how to save the flooring. Varnish, wax, oil, advantages and disadvantages of materials. All the secrets of wood flooring tools.

-

Protecting and impregnating wood with used oil

Impregnation of wood waste oil non-residential buildings. Features of processing and benefits of wood impregnation with engine oil. Preparation of a mixture of waste oil for wood impregnation.