Many homeowners will sooner or later face the problem of replacing old flooring. Of course, this problem is not solved in an instant and is often associated with a substantial waste of material resources, because any work on the alteration of the floor is an expensive pleasure.

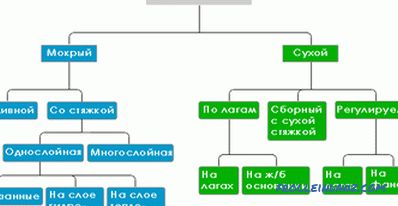

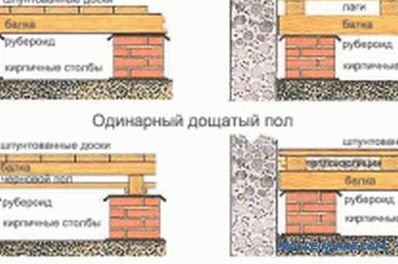

Scheme of a variety of subfloor.

When starting repair work, many are wondering which of the floor arrangement options would be more acceptable. For this it is necessary to consider the main options and conduct a detailed analysis.

The modern system of the construction industry offers 3 ways of arranging floors: a screed in dry and wet versions, design on wooden logs. These species are actively used at the present time, each of them has distinctive features.

Analyzing any of the methods, it should also highlight the nature of the materials used, the technology of installation work. Repair of the floor on logs has significant advantages compared with other coating options. It is necessary to elaborate on each of these options.

Cement screed: features

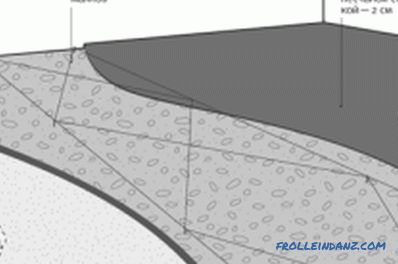

Cement floor screed scheme.

A cement floor screed has the following purpose:

- Aligns the foundations below.

- Hides the pipeline.

- Evenly separates thermal insulation loads.

- Supply of standardized heat absorption by floors.

- Participates in the formation of slopes.

The screed implies a perfect leveling of the base; it makes it perfectly smooth, neat and dry. The flooring acquires a special fortress, which makes subsequent operation practical and convenient.

In terms of technology, the screed appears to be a wet process that leads to wetting of the walls, the ceiling, as well as the surfaces of the neighbors. Besides, it is very difficult to be and live in the room where such work is being carried out.

The fact is that such repairs are often associated with dust and dirt in the room. It is not easy to get rid of this type of litter. Flooded floor dries out for a very long time, the exposure time can reach a month. The wet basis will not allow to lay a long time on a surface facing material.

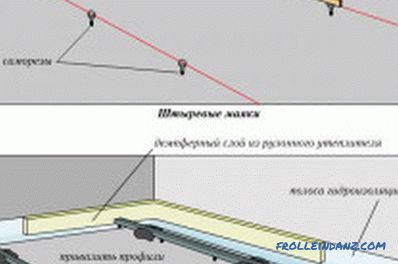

Beacon installation scheme for the tie.

A screed as a way to carry out repairs in a room, even with a high-quality organization, does not allow to obtain ideal results of coating leveling. In addition to this, you should use special mixtures that serve to level the base. These are self-leveling compositions, the cost of which is quite high.

In addition, the coupler is distinguished by a complex process of technological installation. It involves the preliminary preparation of the base, priming, setting beacons, stirring the solution, waiting for the complete drying of the surface.

By choosing this method of repairing the flooring, it is worthwhile to follow the high-quality performance of the work, because it is impossible to alter the finished foundation, and dismantling the previous one will cost a considerable amount, and much effort will be spent.

Among the drawbacks of such a design is a rather complicated calculation of the amount of material needed.

Dry screed: highlights

Floor repair based on a dry screed is a novelty. Compared to this method with a conventional coating of a cement-sand mixture, the first version is characterized by significant positive indicators.

The assembly procedure is characterized by purity, the absence of dust, litter, and water. Such a floor is collected in a short period of time. The ready basis can be operated at once.

Diagram of the dry screed device.

The lack of such a structure is associated with the material used. Evenness coating gives fine expanded clay. However, such a base in the form of a granular substance can give an uneven shrinkage, this is especially observed at the points of movement of residents, such as a corridor, aisles.

In this case, the unevenness of the floor will appear even stronger. GVL is used as a draft, the material is weak and easily broken, it is not able to transfer the loads acting on the floors. Points of active movement of residents begin to grind, crack, push through. The floor is deformed, the quality of the coating suffers.

In addition, paper that stacks on GVL appears to be a favorable area for the growth of fungi and the appearance of mold.

Before a final decision is made on the choice of floor screed, it is necessary to study its features. Preferring one type or another, no need to rush, you should weigh all aspects of this process. The table below will help you figure out the main points.

| Wet screed | Dry screed |

| Need the help of skilled craftsmen during installation work. | The process of carrying out the flooring is carried out according to a simplified scheme, which allows covering people who are not related to the construction specialty. |

| Associated with the treatment of the entire surface in a short period of time. The solution quickly hardens, then it will not be possible to use it for work. | The dry coating is laid by passing through several stages, carrying out a gradual laying of the floor. |

| Floor repair associated with the use of cement is characterized by poor heat retention and insufficient insulation from extraneous sounds. | Expanded clay is distinguished by a good degree of heat retention and excellent sound insulation properties. |

| Wet screed does not allow to place on the surface other coatings, except for the floor base. | Using the natural qualities of expanded clay, such as flowability, any communications, heated floors, electrical wires can be placed at the base. |

Wooden floors on logs

To answer the question which is better - floor on logs or screed, it is necessary to deal with the design features of each of these sides, highlighting their positive and negative points. Thus, the wooden base in the classical sense seems to be an actively used type of floor base, like a cement screed.

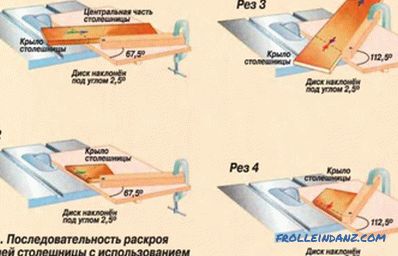

Variants of the board floor.

The main positive aspects of using the structure on the logs are:

- the ability to create a perfectly smooth surface;

- significant savings of material means and forces;

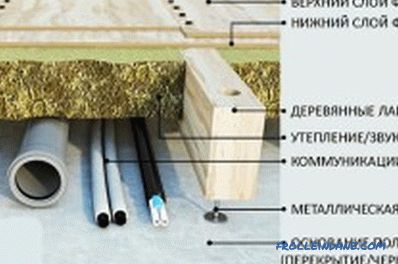

- building capacity for the construction in the subfield of various communications, electrical wiring and engineering systems;

- good heat retention and protection from extraneous sounds;

- reducing the load on old floors in a residential building;

- ability to build ceilings in several levels.

The floor device on the logs has a weak technological basis.

Such structures are characterized by the fact that they are mounted on any shape, in its quality can be bars, brick, roofing material. They are fixed using anchor bolts with one of the most basic methods.

In order for the floor to acquire perfect indicators of evenness, it is necessary to use a laser level. Other tools will not give the desired results. The weak point of such a base will be a frame anchor or a nail made of polypropylene, which simply will not sustain the mass of the entire device. As a rule, after 3 months, such a construction begins to weaken, squeaks appear.

Schemes of modernized wooden floors with logs.

The skilled foreman should carry out the installation of the floor on the logs, because such work requires experience and is notable for its particular jewelery and subtlety of the process. Lay such a structure on the lining material of different dimensions and unequal thickness, observing the norms of construction and adhering to the same level, not every person can.

However, even if the floor is laid incorrectly, it can always be disassembled, while the materials will remain intact. Mount a new facility is not difficult.

Lags, plywood, and floor boards are taken for wooden floors. Wood raw material is characterized by absolute purity from the point of view of ecology, it does not change for a considerable period of time. The gap between the floor and the base contains an air cushion, there is a constant air circulation, due to which the integrity and excellent condition of the materials will be ensured.

Adjustable floors: characteristics

Adjustable floor assemblies.

Floor repair associated with adjustable structures, characterizes the positive qualities of a conventional cement screed, dry option and classic wooden foundations. However, the disadvantages are also inherent. As for the assembly, it is carried out in a short time, there is no any dust, dirt, wet surface.

As a result, the foundation acquires strength, smoothness, it is ready to lay any floor covering. The floor, trimmed with wood, has a warmer base and allows for communication of any kind.

Adjustable designs are based on a simple method of installation work. In the process of using the laser level, you can get flawless indicators regarding the smoothness of the surface. The anchor used in repair fixes the structure as tightly as possible. Lags and plywood are fixed with washers, lock nuts, which provides a good result. Specialist assistance in this case would be superfluous. Assembling the floor resembles the construction of a conventional structure, the stages of work are simple and clear.

Adjustable floors actively use wood as materials, and, as you know, such a base guarantees excellent coating quality, which is manifested in its excellent performance, which distinguishes it from gypsum, cement and expanded clay.

After making some comparison, you should decide what is best. However, often the arrangement of the floors depends on certain conditions, operation and your capabilities. The choice is yours. Good luck!