A foam block house is a great solution for every developer. Such a structure differs among buildings of other materials with a relatively low cost, minimal construction time, resistance to rotting, as well as fire. The walls of the blocks are warm and reliable. In this article we will tell you how to make a house out of foam blocks with your own hands.

Foundation

Foundation Layout

Foundation Layout

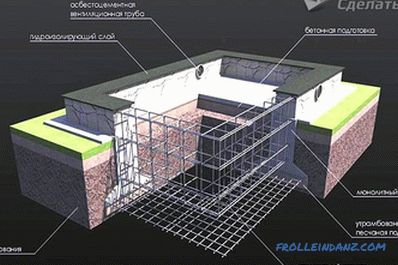

The first step is to create a foundation that can withstand the house from foam blocks:

- We make calculations of the width and depth of the formwork system. The width is equal to the cross section of the structure under construction, and the lower point depends on the climatic conditions of the area and the degree of soil freezing. The depth of the foundation must be at least 500 mm.

- Next, a trench is dug, the depth of which is about two meters.

- Coarse sand (300 mm) is laid at the bottom of the trench. Then the sand cushion is moistened with water and well compacted.

- To impart accurate forms to the foundation, formwork is placed, and strips of roofing material are fixed.

- A fastening belt of reinforcement is installed along the perimeter of the trench.

- Then you can fill the foundation with a special solution (5 parts of rubble, sand - 3, and cement - 1).

- We move the formwork, increasing the construction of the foundation. During pouring, asbestos pipes are arranged for laying the sewers in the places determined by the scheme.

- The concrete mortar should be compacted every 50 cm.

- The foundation "ripens" for at least a month. During solidification, we cover it with ultraviolet radiation and periodically moisten it with water.

- A moisture-proof material should be rolled over the concrete structure.

- From the outside, a blind area is constructed, its width is from one to two meters, and its height is 150 mm. This is done so that natural rainfall is diverted from the first floor or basement. It should be divided into sections to prevent various deformations or ruptures.

Masonry of walls

Masonry of walls from foam concrete

Masonry of walls from foam concrete

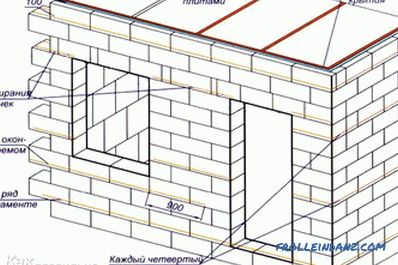

Blocks of foam concrete exceed brick in terms of heat saving and sound insulation, but at the same time, large-scale patching between foam blocks reduces these parameters to a minimum, and "thermal gaps" are formed.

Scheme of foam concrete wall During masonry, it is necessary to comply with all building standards for erection, in other words, to reinforce places under the door and window openings, supporting lintels, etc. using fiberglass weaves. Thus, the house of foam blocks can be insulated.

Scheme of foam concrete wall During masonry, it is necessary to comply with all building standards for erection, in other words, to reinforce places under the door and window openings, supporting lintels, etc. using fiberglass weaves. Thus, the house of foam blocks can be insulated.

It is very necessary to stack the 1st row, checking the verticality and horizontal position of the structure with a water level. Fix the roughness is easy, as the foam blocks are well processable - cut, planing and much more.

Reinforcement of the house from foam blocks

Reinforcement of the house from foam blocks

Holes 0.3 * 0.3 m are cut to install the reinforcement on the surface of the foam block using a circular saw. After which they are filled with a special adhesive solution. In the planking form on the top row of blocks, a reinforcing screed of 0.2 m is made.

Externally, insulation is performed with glass wool insulation or 5 cm wide polystyrene foam. This is necessary for the walls to "breathe." The first row is laid using cement mortar, the second - on a special glue. The height of the base should be 0.4 m.

Next, the mineral webs are fixed outside with plastic anchors. Above them should be fixed wind and hydroprotective material. The front wall is placed on the cement mortar with the principle of a spoonwork. At the same time, the tychkovy row is placed every four rows of spoons. In order to increase air circulation, it is necessary to separate the front masonry and the main wall by 5 cm intervals.

For brick cladding, it is necessary to connect the front masonry blocks with flexible anchors and fiberglass material every 5 rows (with the use of non-bending materials, cracks may form).

Facing the house from foam blocks with facing brick

Facing the house from foam blocks with facing brick

Heat-efficient blocks can be used to build any structure which combine in themselves at the same time three layers: expanded clay concrete, expanded polystyrene and concrete. From the outside, dye is added, and the front side resembles the texture and color of any stone or facing material.

Overlaps

Overlap

Overlap

The design of the overlap is made according to the finished scheme, which gives understanding of the interaction of the beam load, the span size and section bars. You can use boards connected with screws. The ends are sawn off at a certain angle - 60 degrees. Then there is an antiseptic treatment and wrapping with bitumen.

The final beam beams are initially laid, then the rest. Beams of 200 mm and more are placed on the wall structure. The sub-basement should be insulated with a special film and insulation. Above the bars fastened metal crate. Then superimposed mesh of fiberglass and mineral insulation. On the top floor are fastened sheets of plywood and balzatovolokno. At the end we cover the floor with chipboard sheets.

The roof of the house of foam blocks

The roof of the house of foam concrete

The roof of the house of foam concrete

It is necessary to build a tough construction, using bar crate and complementing it with truss trusses. Between the rafters should follow a certain distance - from 600 to 900 mm, the dimensions of the rafters range from 50 to 150 and from 100 to 150 mm. They are installed at an angle of 20 degrees.

Galvanized iron is better suited for skate, but endova makes a good one. To continue the "life" slate roof, you need to paint it with water dispersion coating. In this case, the service life of the roofing material can be increased by 1.5 times.

Installing slate coating

- The boards are fastened at right angles to the rafter legs. Their dimensions are 2.5 * 10 cm and spacing - 0.2 m.

- Then, angular edges of the slate are cut. This is done in order to prevent the layering in their docking.

- Next you need to make holes at a distance of 0.1 m from the edge. Note that the diameter of the hole must be greater than the diameter of the nail.

- With the help of nails with a round cap slate is attached.

- It is necessary to begin to nail slate from the bottom row. Holes are prepared in advance.

A house made of foam blocks is warm, reliable and stable. In this structure you can live with the same comfort as in the brick. The building withstands the vagaries of the weather and is capable of comfortable living in it.

Video

In this video you will learn the features of the laying of foam concrete blocks, and you will find out how it differs from aerated concrete.