Sustainable yields in many regions of our country can only be obtained using protected farming technologies. Polycarbonate is the best material for greenhouses and greenhouses. Buildings of this kind are often erected by owners of personal plots and agricultural enterprises on their own without the involvement of specialists. In such circumstances, a natural question arises, how to choose the best polycarbonate greenhouse in terms of price-quality ratio. The range of panels on the market is large and not all of them are suitable for the construction of such structures.

What kind of polycarbonate is best suited for greenhouses?

To make an informed decision on this issue, it is necessary to understand the properties and technical characteristics of this material. The industry produces two types of polycarbonate: monolithic and cellular, the latter is just used for the construction of greenhouses. Such panels in their parameters best meet all the requirements that apply to roofing materials for such structures.

Before entering the market of cellular polycarbonate, silicate glass and polyethylene film were used for these purposes.

The use of cellular polycarbonate has several advantages over the above listed materials:

1. A small proportion of the sheet.

Depending on the type of panel, its mass is no less than an order of magnitude lower than that of a glass sheet of the same size.

2. High mechanical strength.

Cellular polycarbonate does not crumble into separate fragments like glass upon impact and is not prone to rupture like a polyethylene film.

3. Resistance to climatic conditions.

High material resistance to climatic influences: significant fluctuations in temperature, rain and snow.

4. Low thermal conductivity.

Low thermal conductivity and, as a consequence, excellent insulating properties, which significantly reduces the cost of heating the greenhouse.

5. Translucency and UV protection.

The excellent translucency of the panels in certain types is over 86% and reliable protection from hard ultraviolet radiation.

6. High ductility of the material.

Material plasticity: during installation, it can bend to a certain diameter and stay in this position for a long time.

Cellular polycarbonate is durable, provided that the panels are properly selected and installed, the service life is 10 years or more without significant changes in properties.

An important factor in favor of the choice of cellular polycarbonate as a material for greenhouses is the financial side of the matter. It is much cheaper than glass, and given its high durability, its use is more advantageous than using plastic film. In addition to the direct effect of the choice of cellular polycarbonate as a material for greenhouses, there are side effects.

The use of these panels allows the use of supporting frames with a smaller margin of safety, which will save considerable funds in the construction of such structures. Cellular polycarbonate due to its unique technical characteristics is becoming increasingly common in the construction of greenhouses.

Device and main characteristics of cellular polycarbonate

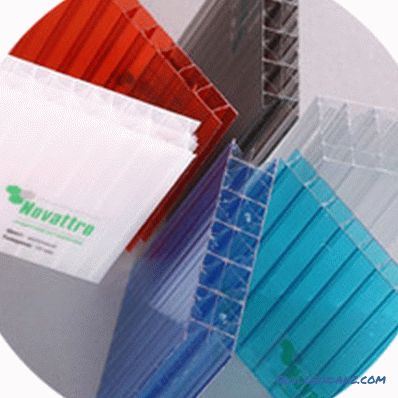

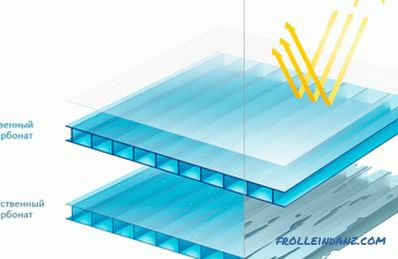

The uniqueness of the properties of cellular polycarbonate is determined by two main factors: the cellular structure and the chemical composition of the material. Polycarbonate of this type is a multi-layered panel with transverse partitions, ensuring its sufficient strength and rigidity. Cells in the cross section of the sheet may have a rectangular and triangular shape in different combinations.

The total number of layers in a material can be from two to four depending on its thickness and type.

The main technical characteristics of the most common types of polycarbonate are presented in the table:

| Sheet thickness, mm | 4 | 6 | 8 | 10 | 16 | 20 | 25 |

| The length and width of the panel, mm | 6000 (12000) * 2100 | ||||||

| Specific material weight, kg / m 2 | 0.8 | 1.3 | 1.5 | 1 , 7 | 2.7 | 3.0 | 3.5 |

| Sheet thermal conductivity, m 2 * ° C / W | 0.24 | 0.27 | 0.28 | 0.29 | 0.42 | 0.56 | 0.68 |

| Light Transmission,% | 83 | 82 | 8280 | 76 | 51 | 58 | |

| Sheet bending radius is minimal , m | 0.7 | 1.05 | 1.5 | 1.75 | 2.8 | 3.5 | 4.4 |

| Change in properties during artificial aging of the material, the conditional | 10 | 20 | 30 |

years The analysis of the data in the table allows us to draw some conclusions, facilitating the process of selection of material for greenhouses.

The most essential characteristics for cellular polycarbonates used in the construction of greenhouses are the following:

- light transmission;

- thermal resistance to heat transfer;

- specific weight;

- mechanical strength;

- service life.

A simple comparison of the parameters for different types of panels allows you to uniquely determine the direct dependence of the listed characteristics on the sheet thickness. Based on the results of this study, we can conclude that the performance characteristics of this material will directly depend on this parameter.

Optimum polycarbonate thickness for different types of greenhouses

The determining factor in which polycarbonate to choose for a greenhouse is the panel thickness, on which its technical characteristics directly depend. One of the most important indicators for the roofing material of the greenhouse is the light transmission. Panels with a thickness of more than 10 mm absorb and dissipate from a quarter to half of the light flux. This circumstance will adversely affect the illumination of greenhouses and will be the reason for lower yields.

The second most important factor for greenhouses is the thermal resistance of a material to heat transfer, which increases with increasing thickness of polycarbonate. This reduces the cost of heating the greenhouse and, accordingly, the cost of production. But, as mentioned above, the increase in thickness will adversely affect the light transmission. The next characteristic of the panel taken into account when determining its optimum thickness is mechanical strength.

Often, in order to save greenhouse production, 4 mm polycarbonate is used. This is quite acceptable if the panels are really high-quality and their thickness corresponds to the nominal value. Some manufacturers in order to reduce costs allow the reduction of this parameter to 3.5 - 3.8 mm. This is imperceptible to the eye, however, during operation, premature destruction of the material under wind load or due to accumulation of snow mass is possible. From the use of such polycarbonate is better to refuse.

When determining the optimum thickness of the cellular polycarbonate, the following factors are taken into account:

- The design features of the framework (radius of curvature of the arcs and the distance between them, as well as between the transverse profiles).

- Climatic zone of the region where the greenhouse is being built.

- The presence of a heating system and the period of use of the structure for its intended purpose.

As practice shows, cellular polycarbonate 4, 6 and 8 mm thick is used for greenhouses. In some cases, 10 - mm panels are used for fairly large permanently existing agricultural facilities. Thicker sheets reduce light transmission and greatly increase the load on the frame, which makes their use impractical.

The protective properties of polycarbonate against ultraviolet radiation

Polycarbonate itself is susceptible to the destructive influence of ultraviolet rays, which under long-term exposure destroy the polymer. To protect against such photochemical processes, on one or both surfaces of polycarbonate, using a coextrusion method, apply a layer of a light-stabilizing substance.

The thickness of this coating is from 0.0035 to 0.006 mm and this is quite enough to protect the sheet from destruction. The protective layer is applied during the production of the material and as a result, it is partially diffused into the substrate.The interpenetration of the light stabilizer and polycarbonate eliminates their delamination, which contributes to an increase in the service life of the material.

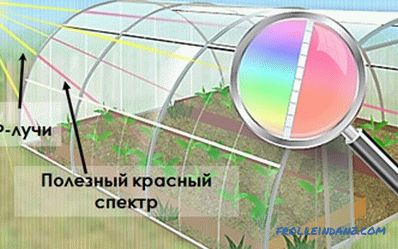

1. Cellular polycarbonate provides reliable protection of plants from exposure to the most dangerous for them hard ultraviolet. Radiation from this part of the spectrum is absorbed and scattered by the panels.

Ultraviolet rays are trapped by a layer of photo stabilizing substance, and this is quite enough for reliable protection of plants from harmful radiation.

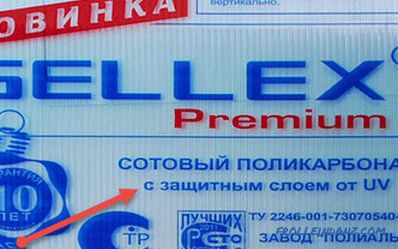

2. Information on the presence of a light-stabilizing layer is reflected in the documentation and on the packaging film. Determining by eye the presence of a protective coating is impossible and one should not believe in unscrupulous suppliers claiming to introduce such additives into the melt of granulate during panel production.

Thus, they are trying to sell low-quality material suitable only for internal work.

Sheet size is most suitable for the greenhouse

The industry produces two main types of panels, dimensions that depend on the thickness of the sheets. The size of a sheet of polycarbonate is 2100 mm wide and 6000 and 12000 mm long, with a tolerable deviation from the nominal value in the transverse direction of not more than 3 mm in the longitudinal direction not exceeding 10 mm. This must be considered when choosing a roofing material for the greenhouse.

In order to make rational and most complete use of the material without cuttings and residues in the manufacture of greenhouse frames, the following factors should be taken into account:

1. The length of the arcs of the power structure is recommended to be equal to 3, 4, 6 and 12 m, which will avoid the transverse joints between the individual sheets.

2. The distance between the bearing elements is chosen so that the joints fall on the profiles. This significantly increases the strength of the roof of the greenhouse.

3. In the manufacture or selection of finished arcs is taken into account the minimum allowable radius of curvature, which depends on the thickness of the sheet.

4. When constructing greenhouses with pitched roofs and vertical walls, their sizes should be calculated so that the sheet of 6 or 12 m is divided without residues.

Accounting for all the above recommendations will allow you to build a solid and durable greenhouse, which during the operation does not require repair and any additional costs.

Please note that the installation of polycarbonate on the frame of the greenhouse is carried out in such a way that the cells go along the slope. At the ends of the greenhouse, the sheet is fixed so that the honeycombs run vertically. This will ensure the removal of condensate from the cells and extend the service life of the material.

Polycarbonate sheet color for greenhouses

Honeycomb polycarbonate manufacturers offer a wide range of panels in different colors. The choice of polycarbonate sheet color for the greenhouse arrangement is determined primarily by the purpose of this structure. It produces plants that need sunlight of a certain spectrum and intensity.

For greenhouses and greenhouses, transparent cellular polycarbonate with maximum light transmission is used. For panels with a thickness of 4 and 6 mm, this figure is up to 85%. The use of colored sheets is impractical because it adversely affects the development of plants and, ultimately, crop yields.

The procedure for selecting polycarbonate in the store

Before you go to the store to buy this material, you should decide which polycarbonate is needed for the greenhouse.

The customer must know the following characteristics of the panels he needs:

Sheet thickness . Usually for the construction of greenhouses used polycarbonate honeycomb thickness from 4 to 10 mm, and its value is determined by the project. When choosing a material, it is possible to measure this parameter with a caliper. A significant deviation from the declared value to the lower side, as a rule, indicates a low quality sheet.

The presence of a light-stabilizing coating . Particular attention should be paid to the presence of a protective coating against ultraviolet radiation from the purchased polycarbonate. This can only be verified by documentation and this information can be found in the certificate of conformity. In addition, the protective film indicates which side of the sheet should be facing the sun.

Material color . For the installation of greenhouses it is necessary to use only transparent polycarbonate.

The required number of panels of different sizes . Check with the seller that you need the size of the material.

Acquisition of high-quality cellular polycarbonate will allow building a reliable greenhouse suitable for seasonal or year-round use.It should be remembered that cheap materials are usually made from recycled or poor quality raw materials and in violation of technology. Little-known manufacturers also often offer products of dubious quality. Experts recommend buying cellular polycarbonate of those brands that have proven themselves on the positive side.

Video: How to choose high-quality polycarbonate