The frame houses are very reliable and durable. At the same time during their construction requires a minimum of materials and effort. Therefore, to build a frame house with your own hands is quite possible. At the heart of the house is a light wooden frame, for the exterior of which different materials are used. Despite the ease of construction of this type of house, there are some peculiarities and rules of construction.

At the heart of the frame house is a light wooden frame, for the exterior of which various materials are used.

Frame house with your own hands 6x8: step by step instruction

For the construction of this type of house you need a non-grounded place, preferably with a good drainage system. The project of the house should be made on the basis of how you plan to use the house: the whole year or only seasonally. The space between the shields, which is filled with insulation, allows you to live comfortably in the house and in winter.

For work, prepare all the necessary materials and tools:

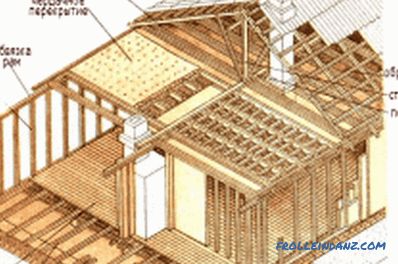

Elements of the frame house construction.

- insulation (mineral wool or polystyrene foam);

- roofing material (ondulin, slate, tiles);

- concrete;

- waterproofing material;

- wood preservative;

- wall paneling or siding for exterior finishing;

- board 40x100 mm for walls, rafters and pediments;

- rebar, channel, pipe, angle, nails;

- self-tapping screws;

- edged boards;

- jigsaw;

- circular saw;

- big pincers,

- construction level,

- screwdriver;

- hammer;

- nail catcher;

- tape measure;

- hacksaw;

- ax;

- concrete mixer.

The frame of the house is usually made of wood. Mostly used oak or larch. Corner joints mounted on the thorn-groove technology. It is necessary to customize building materials as carefully as possible, avoiding gaps. Since wood is rotting, metal fasteners should not be used. Otherwise, the house will be shattered. The best option fasteners - pins of wood.

Outside, the frame must be sheathed with boards that are set at an angle to give the structure strength and rigidity. "Tightly" you should not nail the casing, since in the first year the tree will swell from moisture or shrink in the heat.

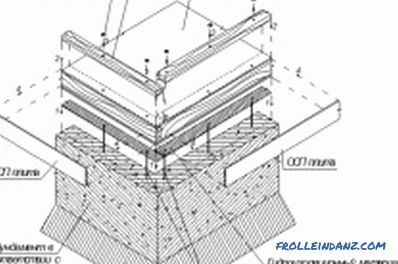

Construction of the foundation

Scheme of the foundation of a frame house.

Construction of the house begins with the construction of the foundation. In this case, suitable columnar, precast or shallow tape. Choosing the type of foundation, you need to decide on its parameters, which depend on the following factors:

- soil type and level of its freezing;

- groundwater level;

- future weight houses.

When digging the pit, please note that its depth should be 15-20 cm below the soil freezing depth. To calculate the approximate weight, for example, a 1-storey 6x8 house, the perimeter (28 m) is multiplied by 1 7, it turns out 47.6. For the 2-storey - 47.6 * 2, the result - 95.2.

Before building the foundation, decide what elements it will consist of, their dimensions, the method of reinforcement, the composition of the concrete solution.

If a columnar foundation is chosen, its main elements are pillars and grillage. The pillars are arranged in 1.5 m increments. The composition of the concrete is determined by such factors as air temperature and groundwater level.

Floor plan of the frame house.

At temperatures above + 5 ° C, concrete B15-B25 is used, in which the main components, sand and cement, are mixed in a ratio of 3: 1, plus crushed stone is added as a filler. Water is added until a homogeneous plastic consistency is formed. If the foundation is erected at a temperature below + 5 ° C and a concrete mixer is used in the manufacture of the mortar, an antifreeze additive is added to the composition.

After completing concrete work, wait at least 7 days. After removing the formwork, make sure that there are no defects in the foundation. When found, they must be corrected. Before building the house, perform work on waterproofing. To do this, as a rule, put 2 layers of roofing material and proceed to the assembly of the frame.

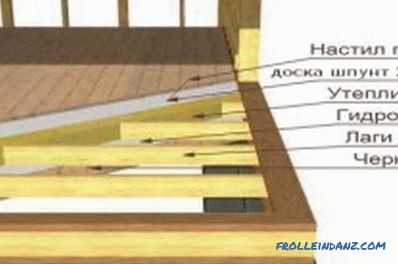

The first stage of construction: piping and floors

The construction of the house begins with paving. The first row of bars is laid on the foundation, along the perimeter of the building and in the places of the bearing walls. Pre-wood is treated with antiseptic. The bottom strapping is attached to the foundation in the following way:

Assembly scheme for frame walls of a frame house.

- On pins with a diameter of 10 mm. They are embedded in the corners of the base or corner piles when casting. A hole is drilled in the timber and fixed to the pin with the help of a nut.

- Anchor bolts with a diameter of 16 mm, which are driven into the frozen foundation at least 100 mm. Bars with each other are fixed with nails 150 mm.

After tying, you need to lay the floor logs and install the vertical posts of the frame.For the log, you need to use boards of 50 x 150 mm, observing a step of 60 cm. In the boards for log, 2 holes are made and logs are attached to the harness on the pads of 26 cm. After this, the draft floor is mounted, for this, take the unedged board. Lay the bars on the floor. In the resulting squares you need to lay the insulating material (foam). Cover the floor with planed boards of 40x150 mm. They should be sealed with staples and wedges, then nailed to the lags. Try to make the floor completely flat. Even small irregularities will lead to a distortion of the whole house.

The second stage - the construction of walls

This stage involves the assembly of the walls of the future house:

The roofing scheme of the frame house.

- First, the bottom trim is made of bars with grooves, between which you need to keep a distance of about 50 cm. This figure depends on the width of the insulating material that will be laid in the frame. The length of the groove should be equal to the width of the board, fixed in it. It will take 2 sets of such bars for the top strapping.

- Next you need to prepare boards, the length of which corresponds to the height of the ceiling. Approximately this is 2.4-2.7 m. Boards are fixed in slots and fastened with temporary braces, this will add rigidity to the frame. To do this, use 2 short stitches for each rack or 1 long - for a few. Having completed the assembly of frame boards, proceed to the installation of boards on the interior partitions.

- Using the grooved bars, we assemble the top trim. It is attached to each rack with 2 nails, which must enter to a depth of at least 10 cm.

- After this, the framework must be reinforced with permanent stubs, the old ones are dismantled. They should be 2 at the top and bottom. They give the structure more strength.

The next step in construction is to fix the ceiling beams. To do this, take a bar 50 * 15. They are fixed, combining with vertical racks. Work is carried out inside the house. The beams are fastened with steel brackets, steel corners, using the technology of cutting grooves and strengthening them with nails.

Door and window openings must be prepared immediately.

In the future, depending on when the house will be used, install single frames or double-glazed windows with double or triple glazing.

The final stage is the construction of the roof of the house

For convenience and safety, you can mount a temporary floor using thick plywood. The first thing raised rafters. To do this, take the bars 50 x 150, their edges are joined end connection at an angle of 50 °. Next you need to make a roof crate. Ondulin, professional sheet, etc.

are suitable for roofing. Next, you can proceed to the frame of the frame and exterior and interior decoration of the house. To finish the exterior walls, you can use siding. It is durable and easy to maintain.

The frame house is built rather easily with its own hands. However, all rules must be followed. Despite the fact that the house of this type is being built quickly, do not rush. It is better to think over each stage of work in advance.

Didn't find the answer in the article? More information on the topic:

-

Quality furniture from shields with your own hands

Furniture from the boards with their own hands. Preparatory work. Full production of a bed from the first to the last step. The time after which you can begin operation.