A warm, fast-built, not too expensive, but at the same time quite reliable house is the dream of any owner. And if it is still possible to build it almost completely with your own hands, then such a private cottage becomes very attractive for land owners.

But what kind of building will fully meet all these requirements?

Our answer is a frame house.

Frame construction history

Frame house under construction

Frame house under construction

Today frame housing construction most popular in the USA and Canada. It was there that several centuries ago, when developing large areas, the main material for building construction was wood, which was used very economically (in the form of a bar and planks, and not like in Russia, it was accepted by whole logs). At the same time, the buildings needed to be built quickly (in a few weeks or a month, and not in a couple of years) and with a minimum of costs. In addition, those Europeans who mastered the new lands had no opportunity to build brick factories or fill deep concrete foundations literally from scratch.

The lightweight wooden frame construction of the house was a way out of this situation. Over time (and the development of colder northern territories), the walls turned into a real sandwich with an effective thermal insulation material inside.

Of course, this type of construction can be found not only in America, but also in Europe and Scandinavia, where for several centuries one-, two-story houses, and three-, four-story buildings of various purposes have been erected in this way.

But in Russia such house-building (in its current form) became popular only in recent decades.

What is it

Arranging the walls of the frame house

Arranging the walls of the frame house

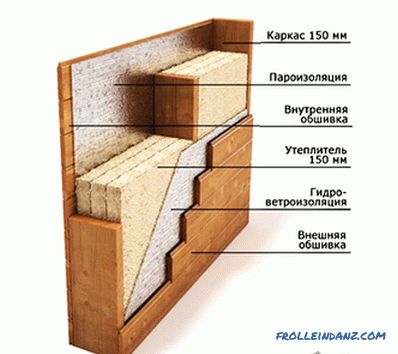

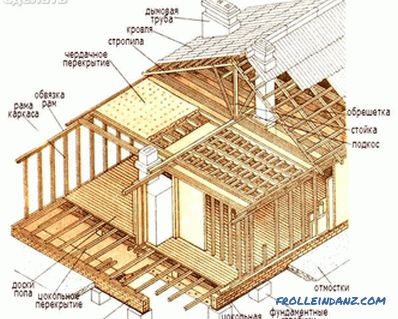

The frame building is a structure consisting of supporting beams and columns (usually wooden, which allows construction to be carried out on their own without the use of special construction equipment), between which there is an insulated insulation. Polystyrene (polyurethane foam, polystyrene foam), mineral wool or "Ecowool" are usually used as a thermal insulation material.

Outside, the insulation protects the cement-shaving plate, OSB plate or moisture-resistant plywood.

"Sandwich" construction of a frame house is relatively easy (compared to brick or small block buildings) and therefore does not require the construction of a cumbersome strip foundation (you can restrict yourself to a solid concrete slab or columnar base).

The Foundation, besides transferring the load from the whole building to the ground, also raises the structure above ground level, thereby preventing moisture from penetrating into it (this is especially important for frame houses having wooden elements).

Construction

Filling of the base for the frame house

Filling of the base for the frame house

There are two options for the construction of frame houses:

- the house is assembled from prefabricated elements manufactured in the factory;

- the building is erected “on site” from separate materials that are assembled into a single structure only at a construction site.

We will consider the second option:

Any construction begins with the development of the project, frame housing construction in this case is no exception, since it is much easier to foresee all the nuances and dimensions first paper and do not suffer then with the adjustment of materials directly on the construction site. A suitable model project can be found on the Internet, but if you want to build something very individual, it is better to order the project documentation in the project group or in an organization engaged in the construction of such houses. The project must have foundation drawings, floor plans, facade and cuts, as well as roofing and floor plans.

Device for the frame of the frame house

Device for the frame of the frame house

In accordance with the project, the foundation of the building is initially performed. Most often choose the column type, whose elements on top are connected by a grillage into one rigid structure. Work on the construction of this type of foundation can be done independently (with the help of one or two assistants).

When casting a grillage (or one continuous reinforced concrete slab, which will be the basis for the frame), it is necessary to check the horizontal position of its upper surface.

While the foundation is gaining the strength you need (it takes about a month), you can buy material for building a house (the required number and dimensions should be calculated according to the project):

- waterproofing material

- lumber (the length and size of the section depends on the size of the premises and the thickness of the wall);

- various fasteners for assembling the frame (screws, nails, anchor bolts, etc. .);

- antiseptic and fire retardant for wood;

- insulation;

- plywood, OSB or DSP for lining;

- material to assemble the roof of a building (waterproofing, lumber, roofing material, insulation);

- super-diffusion membrane for vapor barrier walls, plus a simple vapor barrier.

Mounting the corner stand of the frame

Mounting the corner stand of the frame

Do not forget to prepare a tool for working with wood, and also building level, roulette, punch and other necessary "little things".

The next stage is the processing of all the lumber used in the construction of the house with antiseptics (this will reduce the rate of wood decay) and fire retardants (the wood will be able to resist the effects of fire longer, and you will have a few extra minutes to leave the burning building) .

Installation of the binding beam

Installation of the binding beam

Now you can proceed to the construction of walls. Let's start with laying the bottom trim:

- we place ruberoid on the top of the foundation;

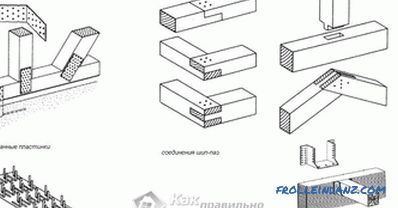

- then follows the bottom trim, which can be joined at the corners in one of the popular ways, additionally strengthening the junction with nails or anchor :

- we check the horizontal perimeter, as well as the correspondence of the diagonals and angles,

- we attach the timber to the base with anchor bolts with a step of not more than 1 meter;

- again we check the horizontal position, angles and diagonals.

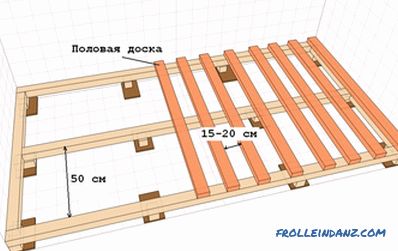

Next, we proceed as follows:

Methods of fastening a timber

Methods of fastening a timber

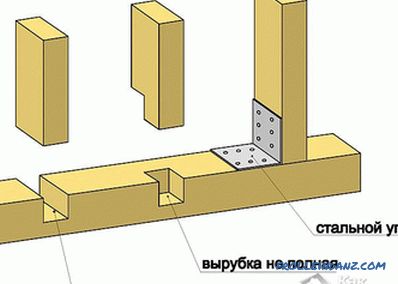

- Install the vertical frame posts, starting with the corner pieces. Connect them to the bottom trim with the help of reinforced steel corners:

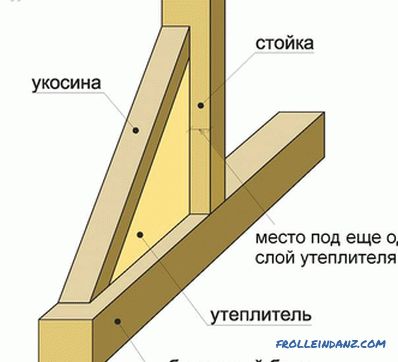

- In order for the pillars not to move, fasten them diagonally on one side with a board.

- Do not forget the window and door openings, since the distance between the vertical supports in these places will differ from the usual (in the plane of the wall without openings).

Fastening the racks with the steel angle

Fastening the racks with the steel angle

- Secure the top trim bar with using steel corners.

- Check the verticality and horizontal position of all elements.

Frame construction technology

Frame construction technology

- Secure each rack with a permanent bar from a small bar cross-sections:

- Install and fix the ceiling beams with steel corners.

- Perform a truss structure, batten, lay the roof covering.

- Fill the house frame with plywood, OSB or DSP from the outside.

- Secure the vapor barrier membrane with a construction stapler (later you will nail the crate over it and fix the siding).

- In the space between vertical supports firmly lay insulation.

- Close the vapor barrier insulation by attaching it to the frame posts with a stapler.

- Fill the inside of the structure with plywood, DSP or OSB.

Video: features of the Scandinavian house building technology

Video: about Canadian construction technology

Photos

The frame house on two floors

The frame house on two floors

Tying using steel angle

Tying using steel angle

With facing the block house

With facing the block house

Cladding with clapboard

Cladding with clapboard

House on a wooden frame

House on a wooden frame

If your budget allows, order the construction of a turnkey frame house. Alternative options can be at home from SIP panels, from sandwich panels, from a bar.